An automatic stripping device

An automatic stripping and material technology, applied in the direction of packaging, transportation and packaging, sending objects, etc., can solve the problems of wasting labor and manpower, low production and processing efficiency, and high labor cost, and achieve the effect of saving manpower and improving production and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

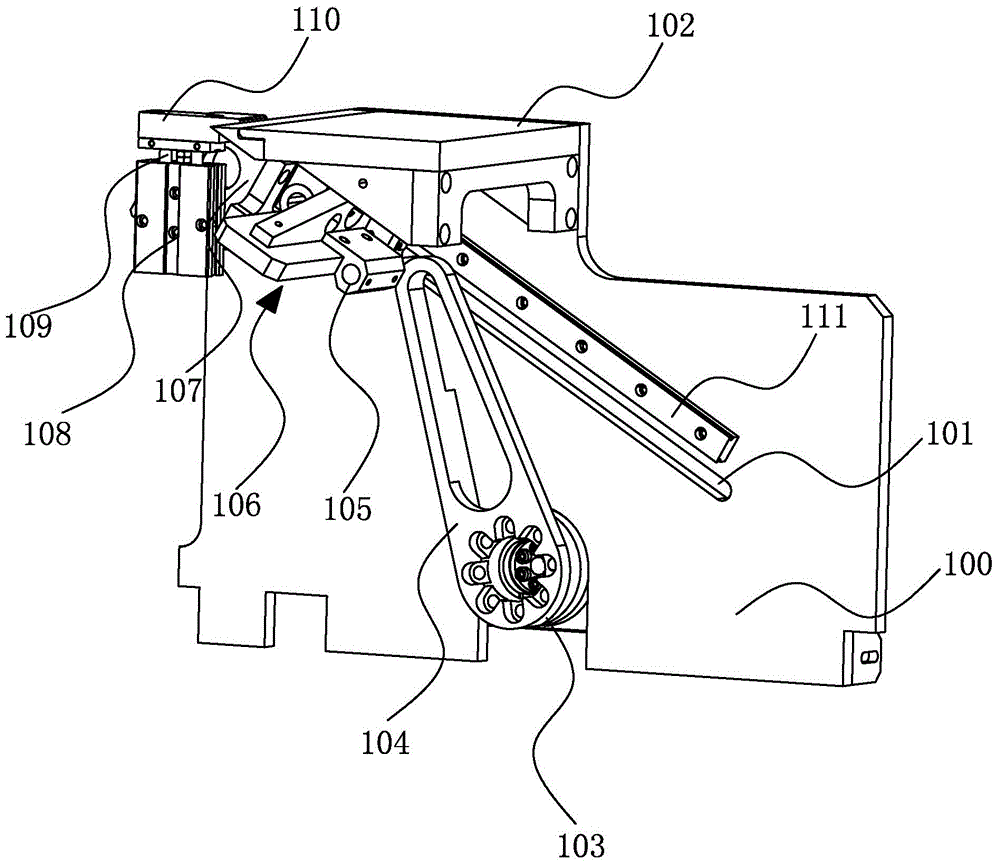

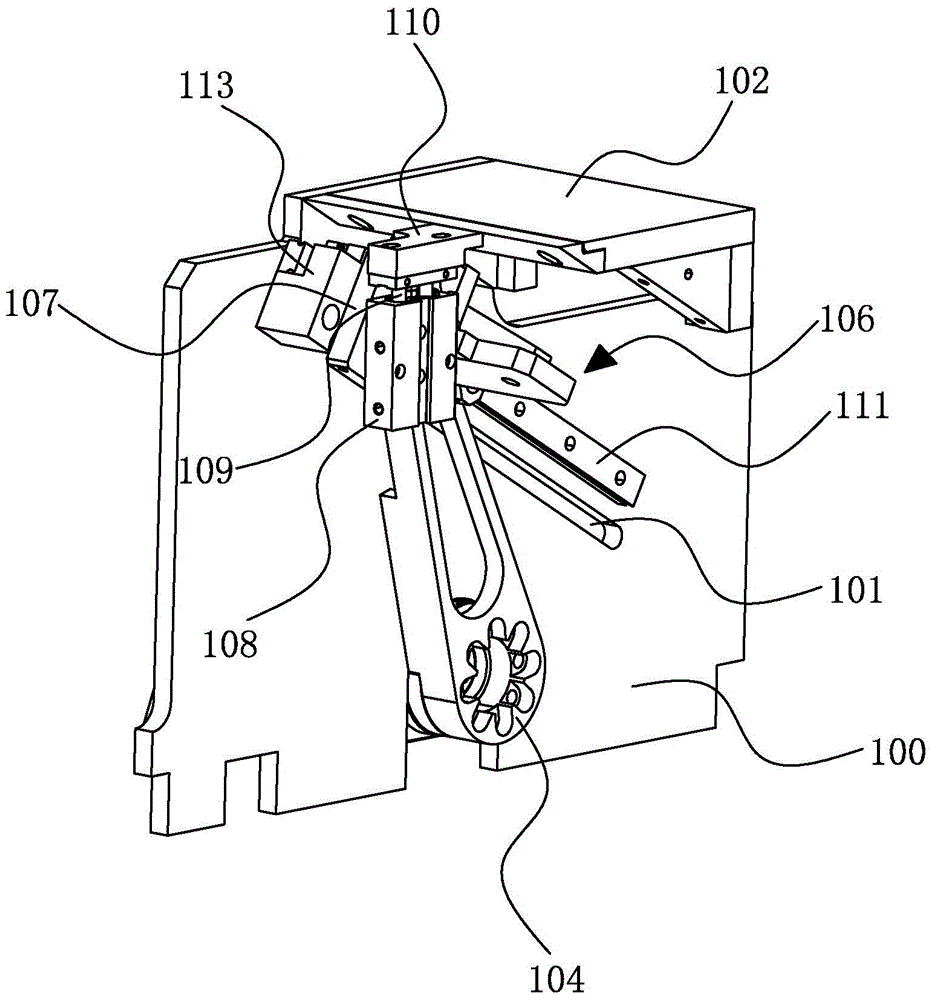

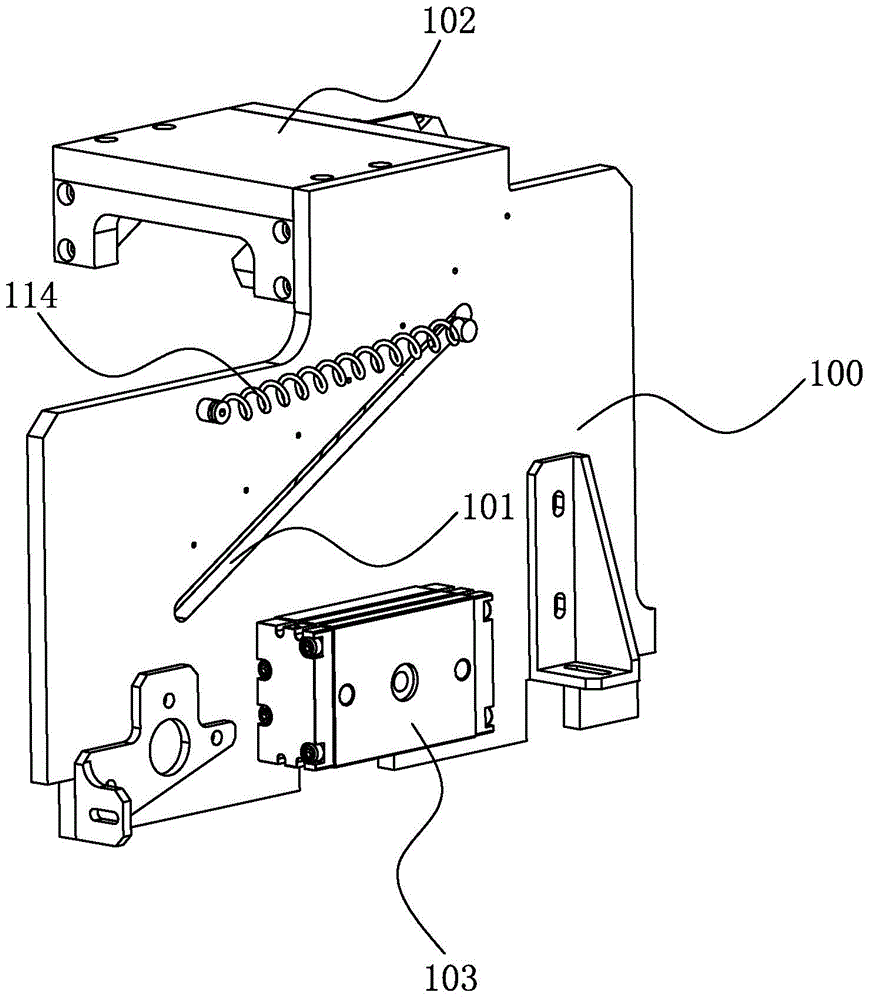

[0032] Please refer to Figure 1 to Figure 4 shown, where figure 1 It shows the schematic diagram of the first angle of the automatic peeling device of the present invention in a preferred embodiment, figure 2 It shows the second angle schematic diagram of the automatic peeling device of the present invention in a preferred embodiment, image 3 It shows the schematic diagram of the third angle in a preferred embodiment of the automatic peeling device of the present invention, Figure 4 A schematic diagram of a clamping cylinder, a clamping block, a supporting plate and a connecting structure in a preferred embodiment of the automatic peeling device of the present invention is shown.

[0033] In a preferred embodiment, the automatic peeling device of the present invention cooperates with the grasping structure to peel off the material with the film, the film can be a release paper, the grasping structure grasps the material, and the grasping structure can For manipulator, d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com