Automatic sheet material stripping structure

An automatic stripping and sheeting technology, applied in the direction of labels, packaging, labeling machines, etc., can solve the problems of manpower consumption, LOGO10 dirt and damage, LOGO dirt, etc., to achieve the effect of solving dirt and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

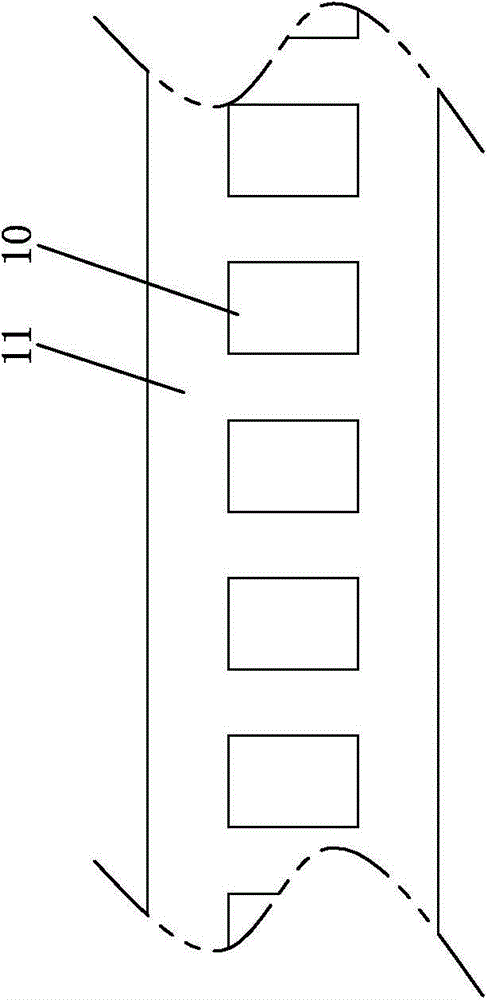

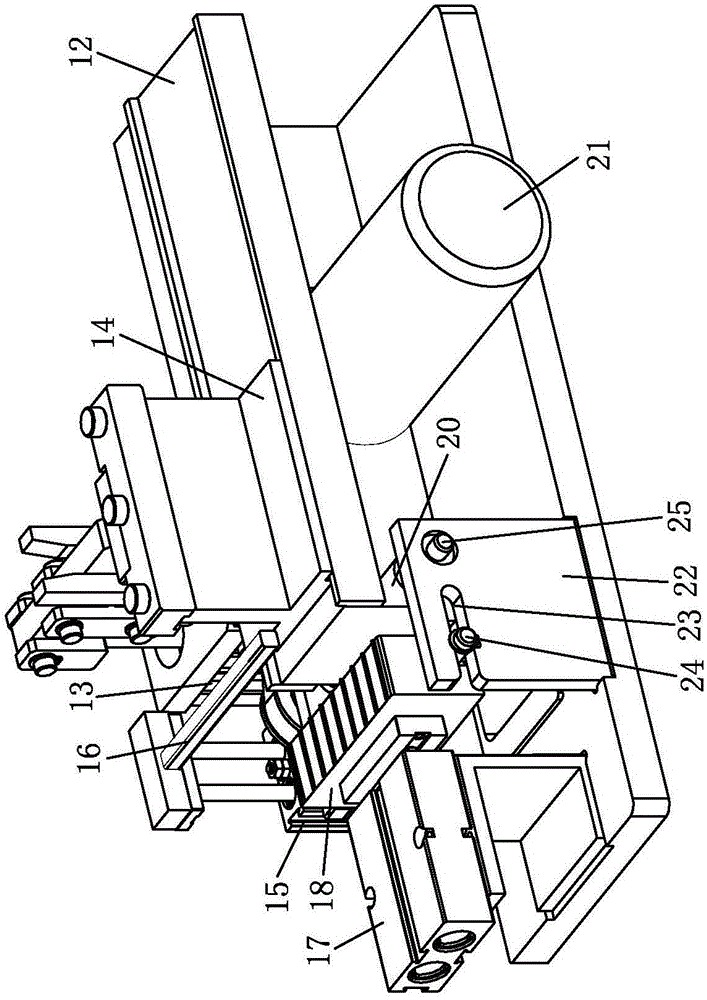

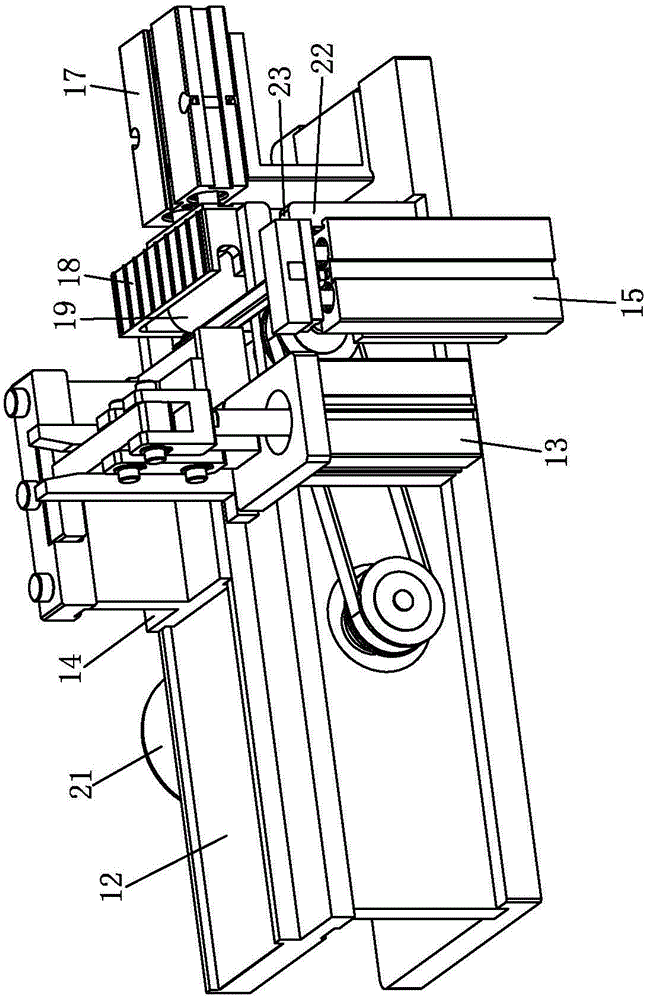

[0023] see figure 1 , figure 2 , image 3 and Figure 4 shown, where figure 1 A schematic diagram of the LOGO pasted on the sheet is shown, figure 2 A schematic diagram showing a preferred embodiment of the sheet material automatic peeling structure of the present invention and an angle, image 3 A schematic diagram illustrating another angle of a preferred embodiment of the sheet material automatic peeling structure of the present invention, Figure 4 A partially exploded schematic diagram of a preferred embodiment of the sheet material automatic peeling structure of the present invention is shown.

[0024] In a preferred embodiment, the sheet material automatic peeling structure of the present invention is used to automatically peel off the LOGO10 from the sheet material 11, and the sheet material automatic peeling structure includes:

[0025] A support frame 12, on which a sheet material 11 is placed, and a plurality of LOGO10 are sequentially pasted on the sheet ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com