Prestressed rock bolt foundation with replaceable bolts

A rock bolt and prestressing technology, which is applied in the direction of basic structure engineering and construction, can solve the problems of smaller diameter, increased cost, and uneven stress of the bottom flange, so as to improve economic value, save maintenance costs, and replace construction easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

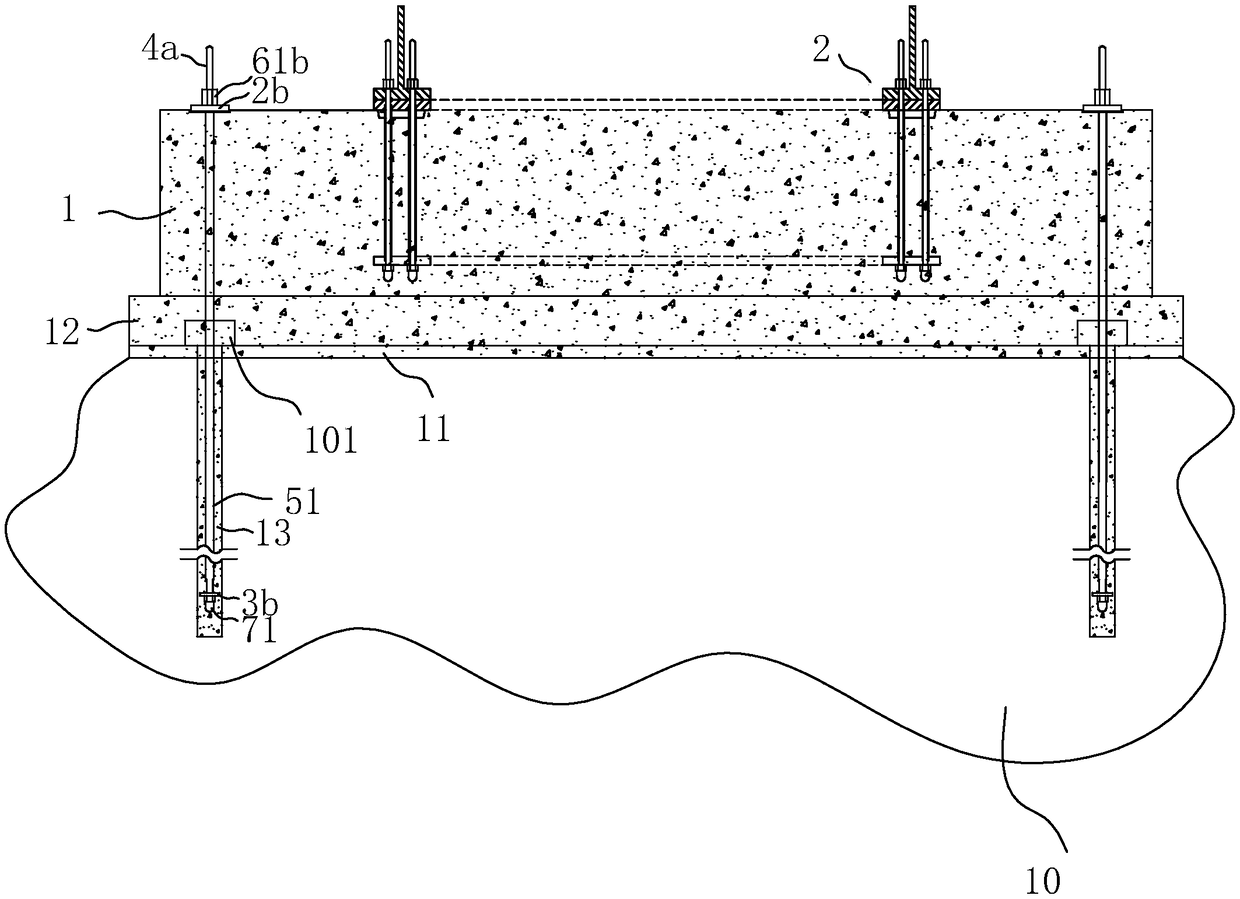

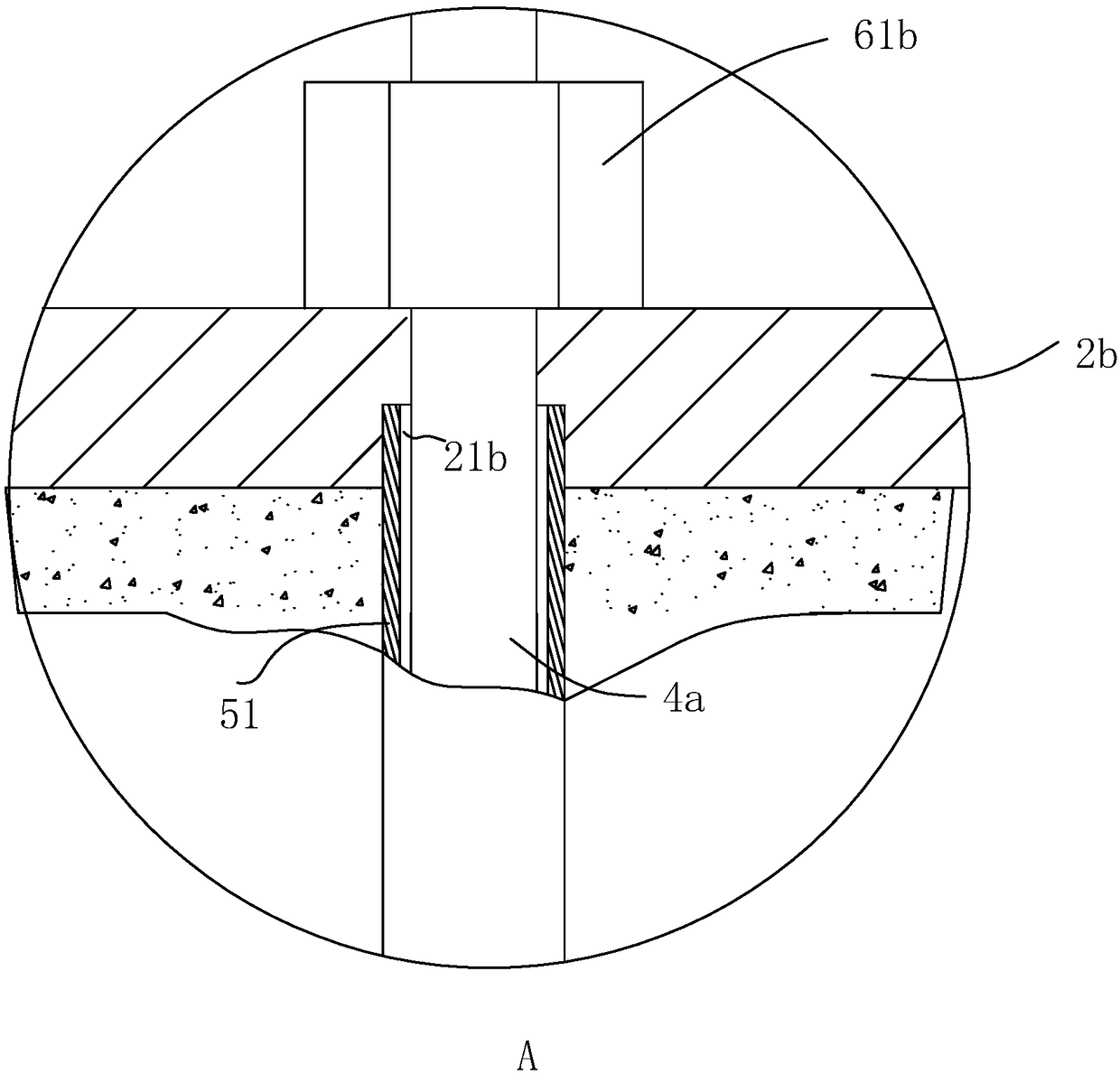

[0052] Embodiment 1, see Figures 1 to 2 As shown, a prestressed rock bolt foundation with replaceable bolts includes a poured concrete leveling layer 11 poured on the rock mass 10, a concrete cushion 12, and a cylindrical concrete cap 1 and embedded in the concrete cap 1 Anchor cage ring assembly 2 in the middle, prestressed rock bolts 4a are distributed around the concrete cap 1, and prestressed rock bolts 4a pass through the top bolt fixing plate 2b, concrete cap 1, concrete cushion 12, polyethylene The benzene plate 101 and the concrete leveling layer 11 are inserted into the prestressed rock bolt hole of the rock mass 10 .

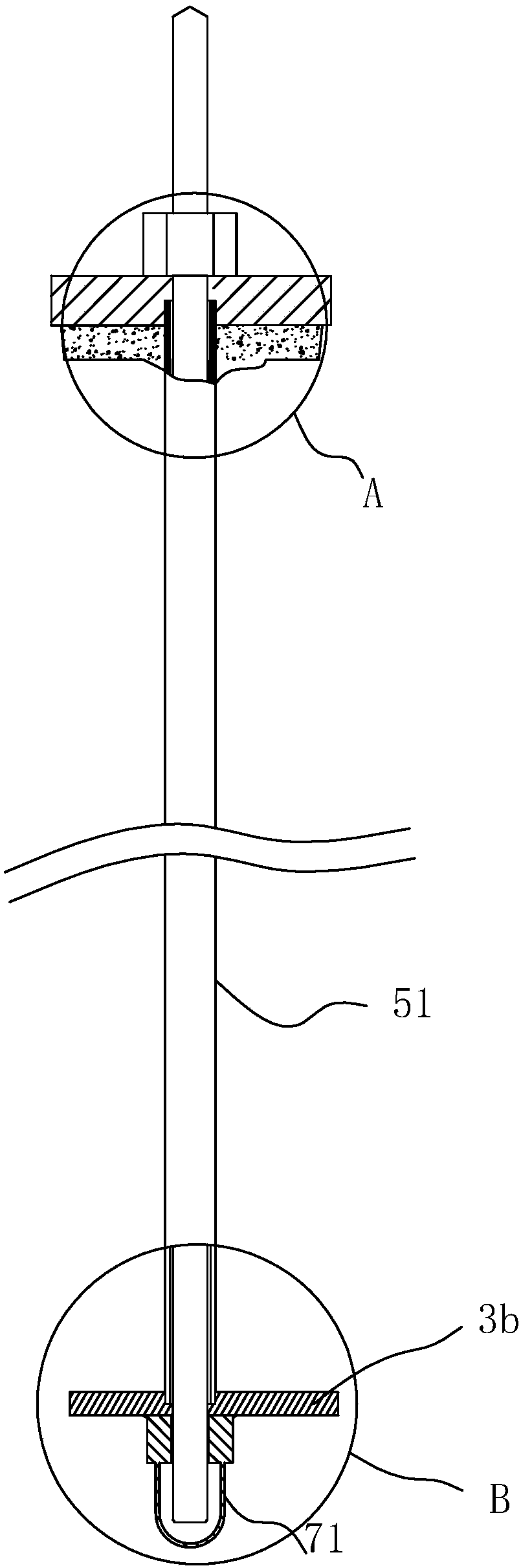

[0053] The outer casing of the prestressed rock bolt 4a is provided with a concrete rigid casing 1 51 for isolation, and the two ends of the rigid casing 51 are sealed and connected.

[0054] The upper end of the prestressed rock bolt 4a is connected to the top bolt fixing plate 2b through the top nut 61b, and the lower end of the prestressed rock bo...

Embodiment 2

[0062] Embodiment 2, see Figure 9 and Figure 10 , a prestressed rock bolt foundation with replaceable bolts. Compared with Embodiment 2, the difference is that the prestressed rock bolt 4a is divided into two parts: the first prestressed rock bolt 41a, the second prestressed rock bolt Rod 42a, connecting sleeve 43, the first prestressed rock bolt 41a and the second prestressed rock bolt 42a are provided with mounting holes 431 on the end face of the connecting sleeve 43, and the rigid sleeve 51 is sleeved on the first prestressed rock bolt On 41a, the lower end of the first rigid sleeve 51 extends into the installation hole 431 , and the diameter of the installation hole 431 is equal to the diameter of the first rigid sleeve 51 .

[0063] In this embodiment, the top end of the first prestressed rock bolt 41a is set in a flat shape, so that it can be taken out with a wrench.

Embodiment 4

[0064] Embodiment 4, see Figure 11 As shown, a prestressed rock bolt foundation with replaceable bolts differs from Embodiment 1 in that in the anchor cage ring assembly 2, the anchor bolt 4b is a double-single structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com