Pre-stressed foundation with replaceable anchor bolts

A prestressed and anchored technology, applied in infrastructure engineering, construction, sheet pile walls, etc., can solve problems such as difficulty, time-consuming, labor-intensive cost, and inability to realize the reuse of concrete foundations, so as to save maintenance costs and avoid risks. , the effect of eliminating hidden risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

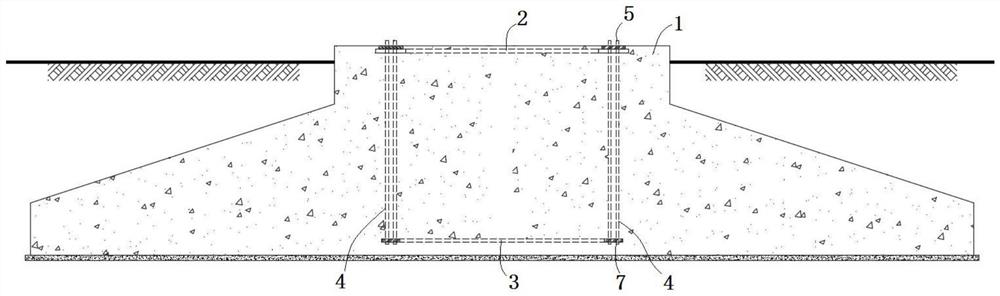

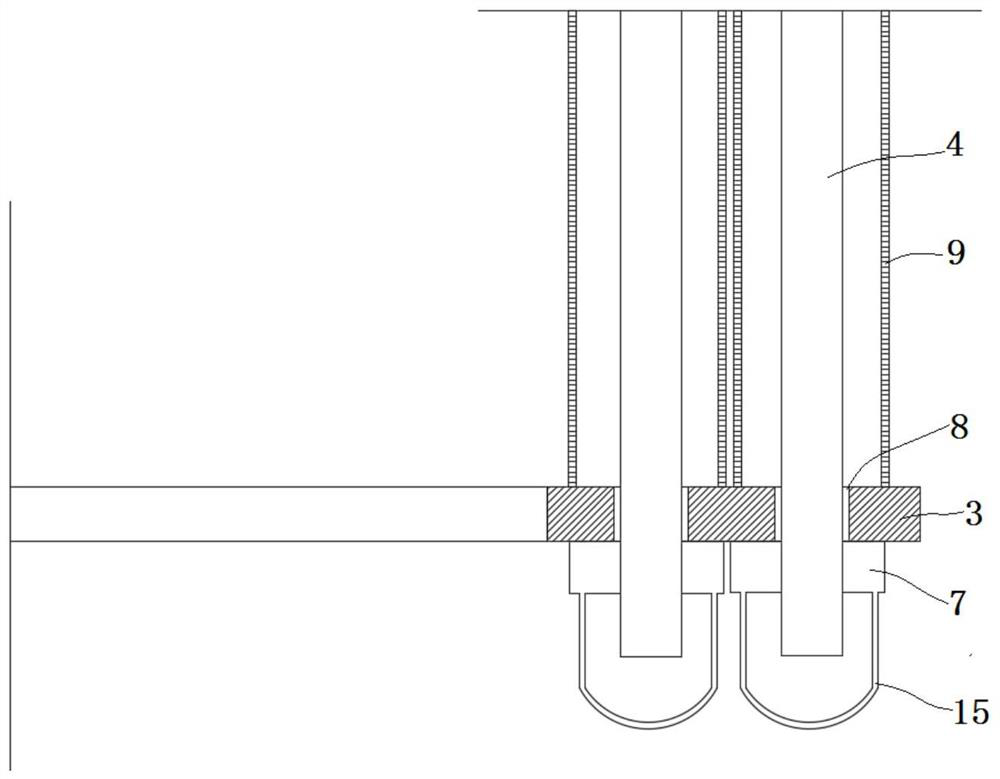

[0032] like figure 1 As shown, a prestressed foundation with replaceable anchor bolts includes a concrete foundation 1 formed by pouring reinforced concrete, and a prestressed anchor bolt 4 assembly embedded in the concrete foundation 1 . The concrete foundation 1 can be a hollow structure, and a manhole can be arranged on the top of the hollow structure for workers to enter into the concrete foundation 1 to perform relevant maintenance work. In this embodiment, the prestressed anchor bolt 4 assembly has a ring structure, and the inner and outer steel formworks are respectively provided on the inner and outer sides of the prestressed anchor bolt 4 assembly to increase the stability of the concrete around the prestressed anchor bolt 4 assembly.

[0033] The prestressed anchor bolt 4 assembly includes an upper anchor plate 2 embedded in the top of the concrete foundation 1, a lower anchor plate 3 embedded in the concrete bottom, and several prestressed anchor bolts 4. The upper ...

Embodiment 2

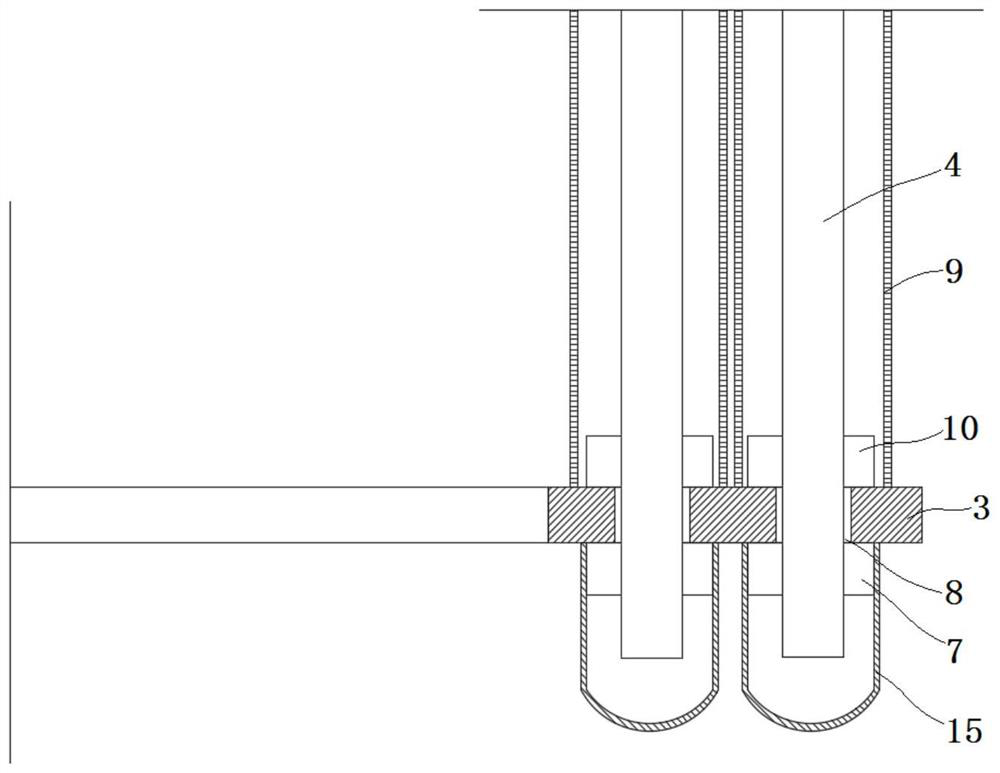

[0038] like image 3As shown, the bottom of the prestressed anchor bolt 4 is provided with a third nut 10 on the upper part of the lower anchor plate 3 . When the anchor bolt breaks, the prestressed anchor bolt 4 broken at the lower part will detach from the lower anchor plate 3 downward due to the reaction force, so that the connection between the prestressed anchor bolt 4 and the lower anchor plate 3 will fail, and the adjacent prestressed anchor bolt at the fracture will be seriously damaged. The support of the bolt 4 is balanced, and the thread of the second nut 7 is easily damaged, and the prestressed anchor bolt 4 cannot be connected again due to thread deformation. A third nut 10 is arranged on the top of the lower anchor plate 3, so that the bottom of the prestressed anchor bolt 4 is fixedly connected to the lower anchor plate 3. When the anchor bolt breaks, the prestressed anchor bolt 4 is locked by the second nut 7 and the third nut 10. On the lower anchor plate 3, ...

Embodiment 3

[0042] like Figure 5 As shown, the inner side or the outer side of the first locking structure 14 is provided with a dismounting thread 16, the direction of rotation of the dismounting thread 16 is opposite to that of the external thread 13, and the thread radius of the dismounting thread 16 is greater than the thread radius of the internal thread 12 .

[0043] The first through hole 6 of the upper anchor plate 2 is provided with a shrinkage cavity structure 17, and the upper part of the shrinkage cavity structure 17 is provided with a second locking structure 18 wider than the aperture of the first through hole 6. The shrinkage cavity The lower part of the structure 17 is inserted into the first through hole 6, and the shrinkage cavity structure 17 is provided with a third through hole 19 through which the prestressed anchor bolt 4 passes. In specific use, the shrinkage cavity structure 17 is installed on the upper anchor plate 2, the shrinkage cavity structure 17 is insert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com