Fuel injector and control valve thereof

A technology for controlling valves and injectors, which is applied to fuel injection devices, fuel injection devices with anti-corrosion measures, machines/engines, etc., to achieve reliable functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Some possible implementations of the present application are described below with reference to the accompanying drawings.

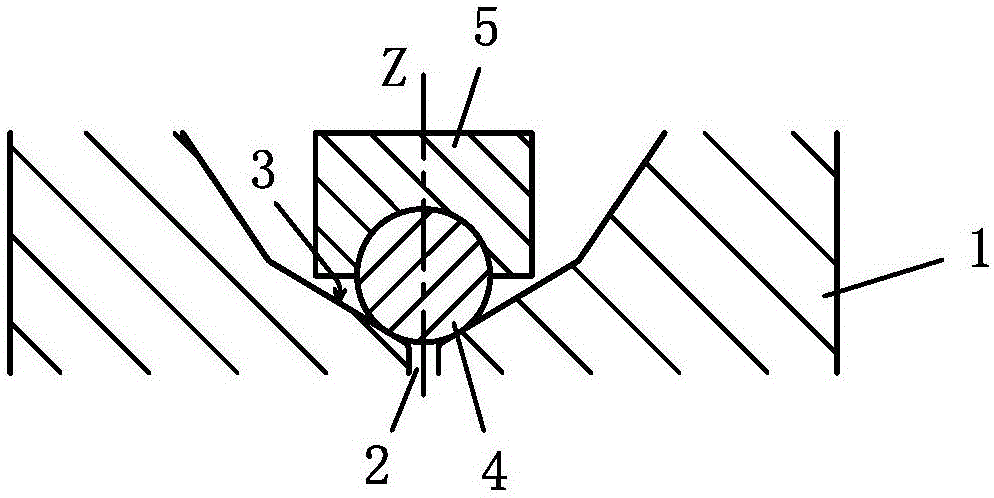

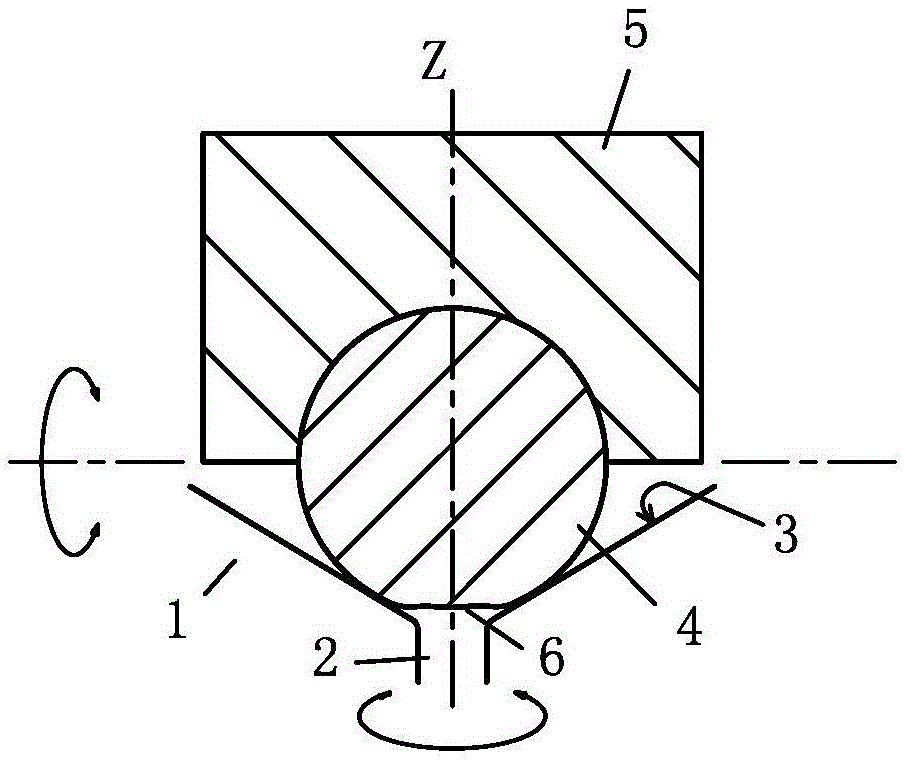

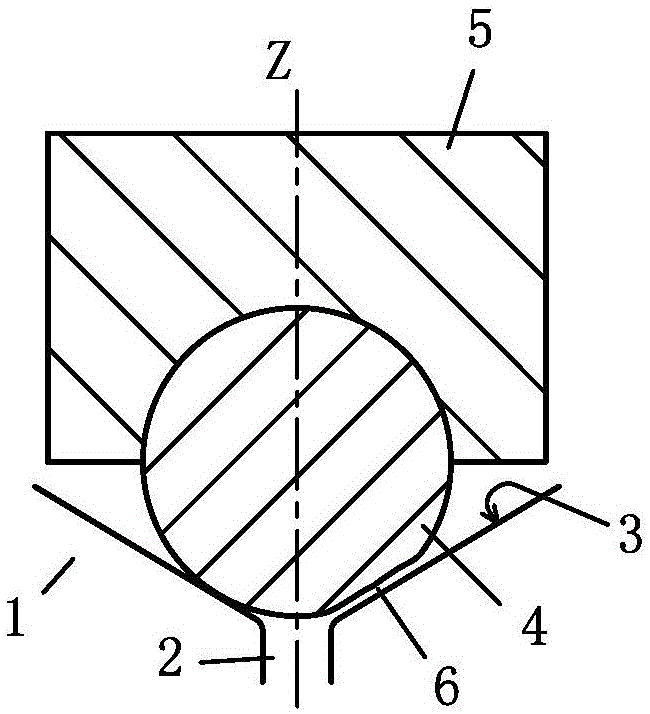

[0025] Figure 4 The middle part shows a fuel injector for injecting fuel into an engine according to a possible embodiment of the present application, especially an injector in a diesel common rail injection system. The fuel injector comprises a control valve and an injection valve assembled together, for example, they may be assembled in a common injector housing 8 (not shown in detail). The improvements of this application relate to control valves, therefore Figure 4 Only the relevant part of the control valve is shown in . The injection valve is combined on the front side of the control valve ( figure 1 the lower side in the center), toward the engine. The control valve is switchable between an open state and a closed state. By controlling the opening and closing state of the valve, the fuel injection action of the injection valve is cont...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap