Heat exchanger components and air conditioners

A technology of heat exchangers and air conditioners, applied in heating methods, household heating, household heating, etc., can solve problems such as tight buckles, inconvenient disassembly, and unfavorable maintenance, so as to improve production efficiency and realize The effect of automating production and reducing the number of constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the accompanying drawings and examples.

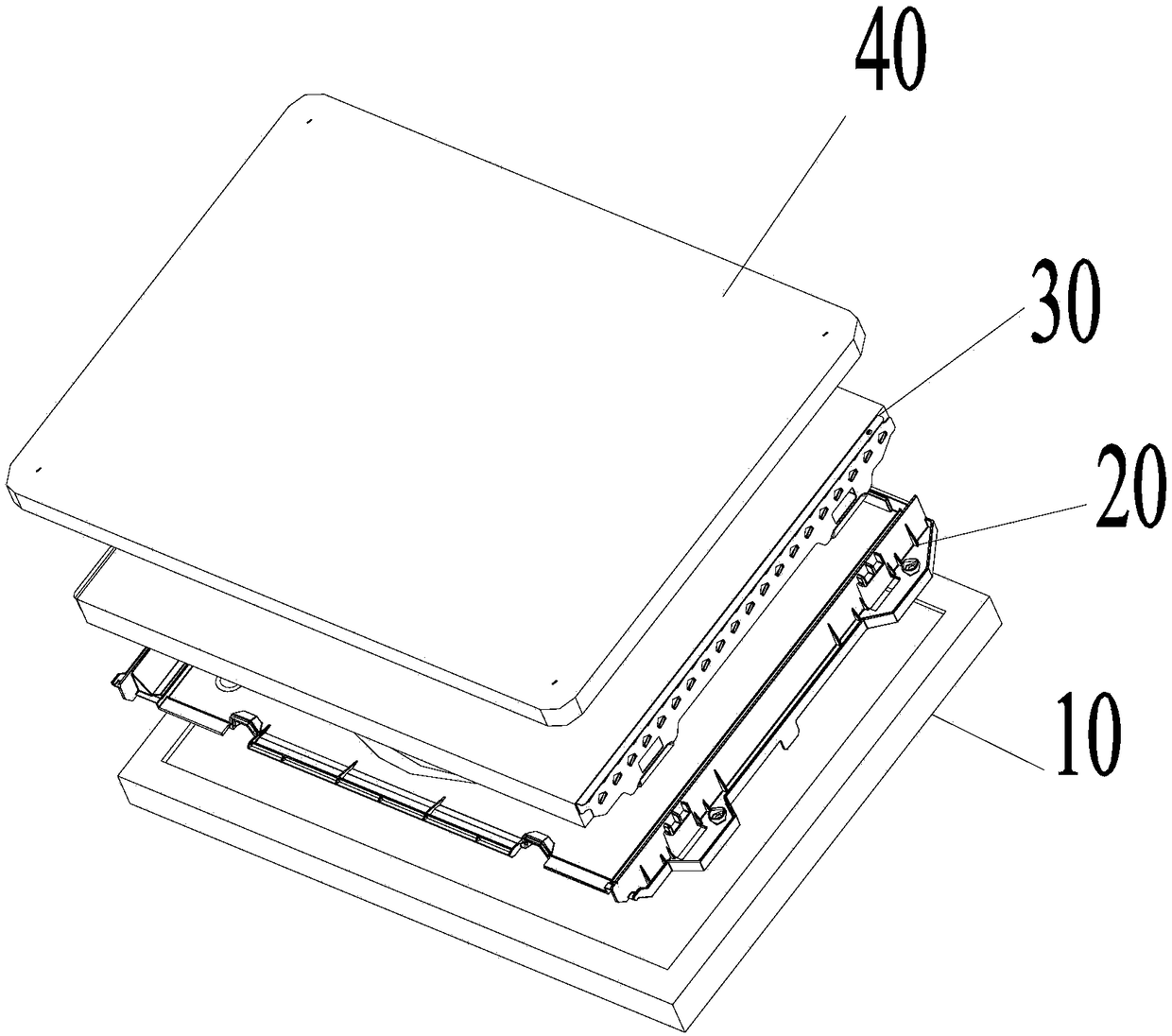

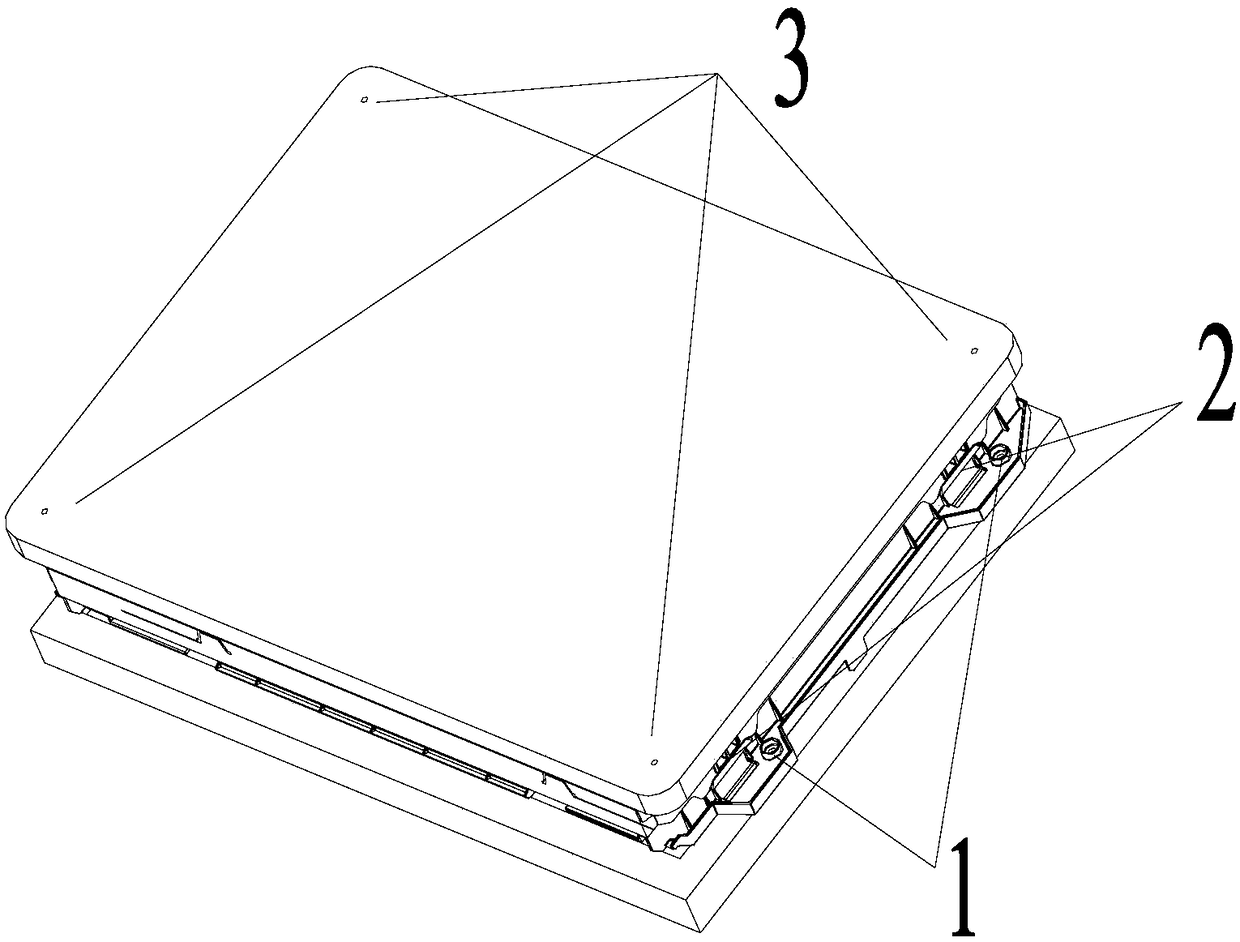

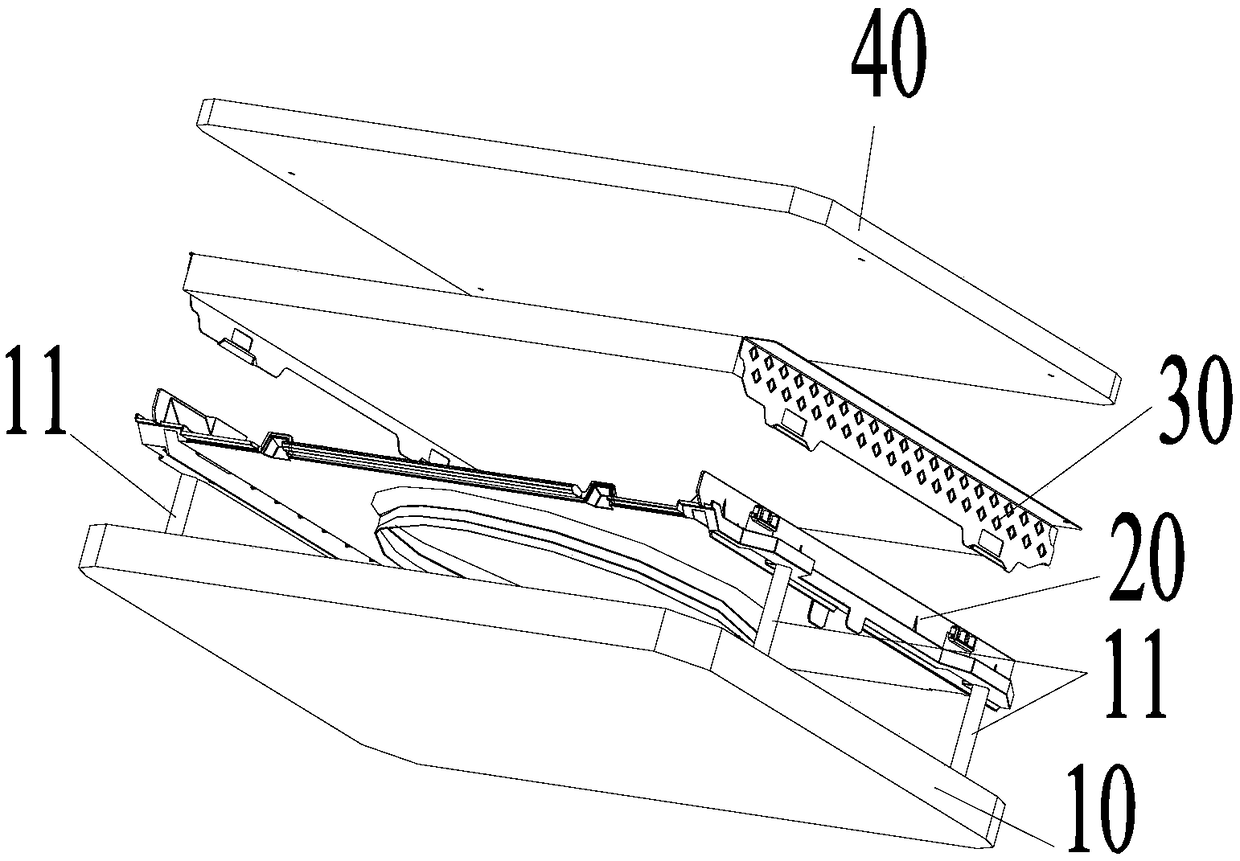

[0021] Such as Figures 3 to 5 As shown, the heat exchanger assembly according to the present invention includes a bottom shell 10, a flow guide ring 20, a heat exchanger 30 and a top cover 40, the bottom shell 10 is provided with a fixing column 11, the flow guide ring 20, the heat exchanger 30 And the top cover 40 is provided with a fixing hole 12 that cooperates with the fixing column 11, and the fixing column 11 is penetrated in the fixing hole 12 to fix the bottom shell 10, the guide ring 20, the heat exchanger 30 and the top cover 40, thereby reducing constraints Quantity is more conducive to realizing automated production, improving production efficiency, and improving the convenience of after-sales maintenance.

[0022] Specifically, the number of fixing posts 11 can be 4 to 8 as required, and at least some of the fixing posts 11 are distributed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com