Grating external cavity semiconductor laser and quasi-synchronous tuning method

A technology of semiconductors and lasers, applied in the field of conductor lasers, can solve problems such as the complexity of mechanical systems, unfavorable laser structure design, adjustment and application, and increased instability factors, so as to achieve large room and space, easy adjustment, and simple adjustment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be described more fully hereinafter with reference to the accompanying drawings, in which exemplary embodiments of the invention are illustrated.

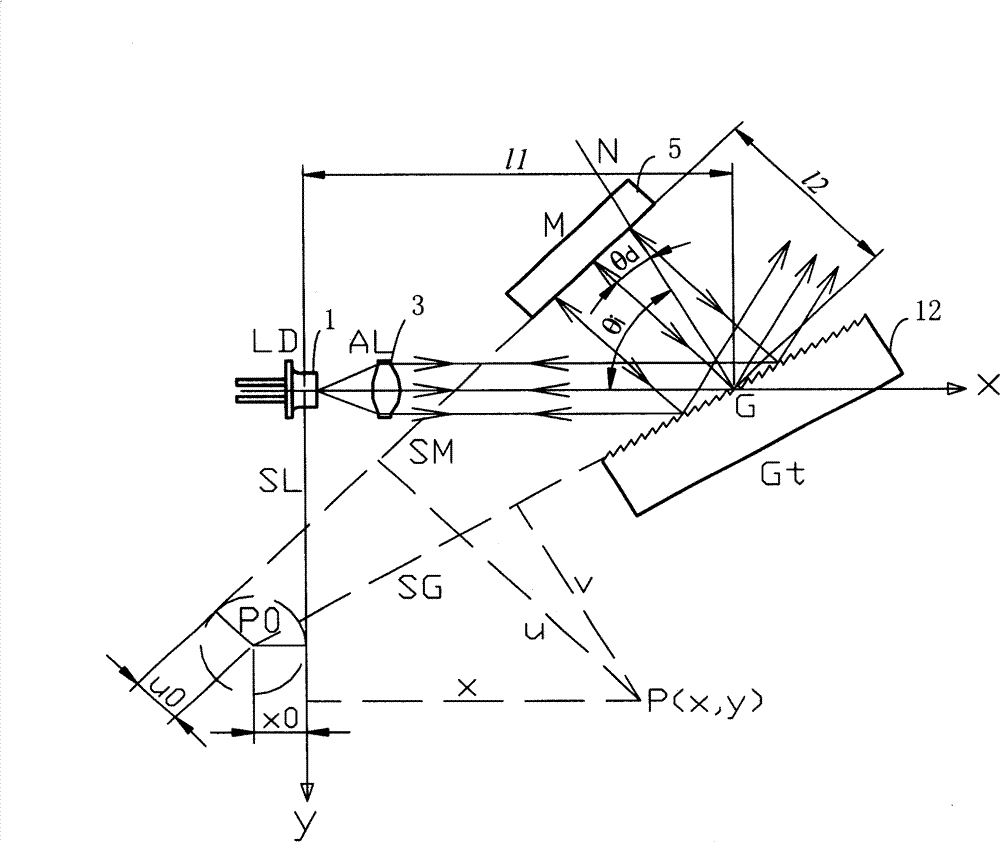

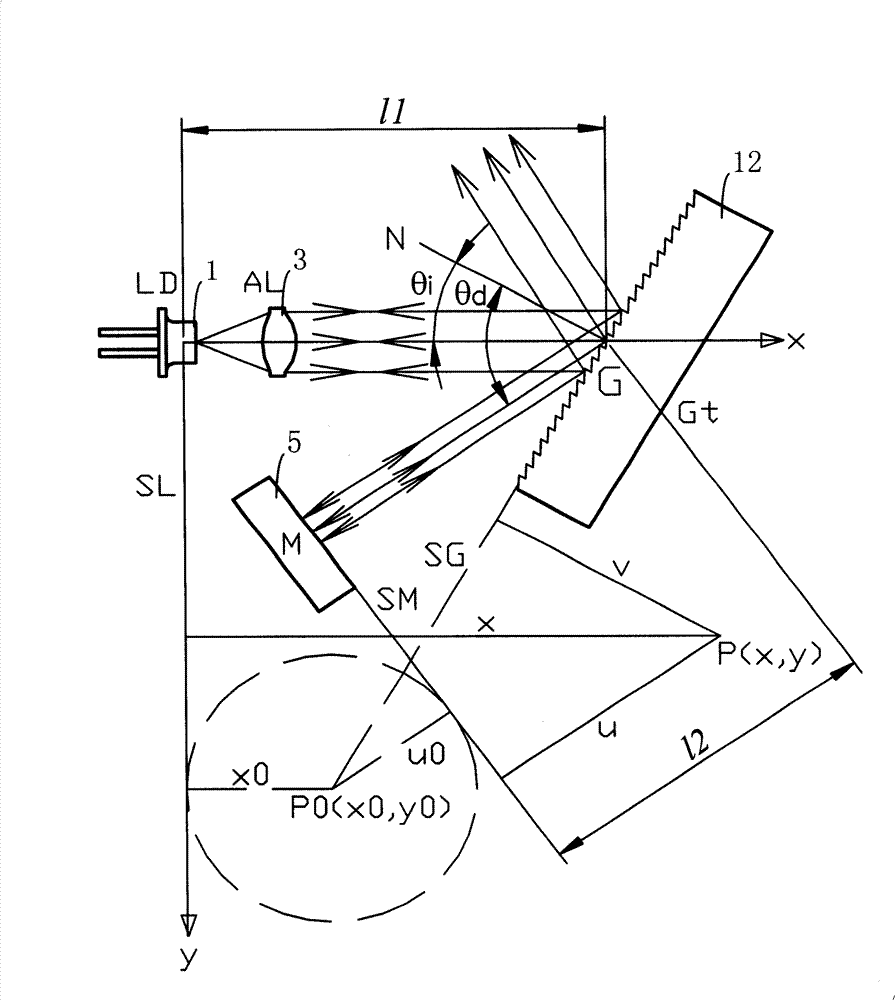

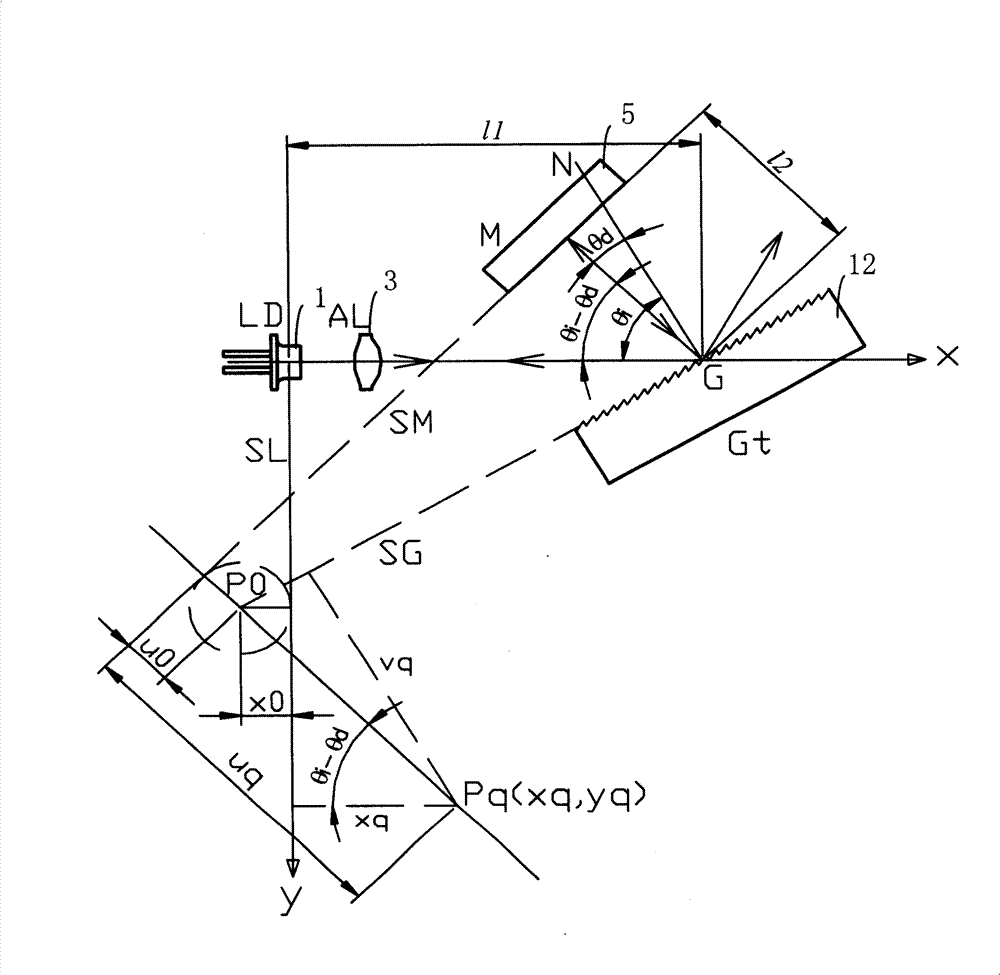

[0052] The invention proposes to adopt quasi-synchronous tuning method to realize continuous tuning of laser frequency, which includes conventional synchronous tuning conditions. The quasi-synchronously tuned grazing incidence (Littman) structure grating feedback external cavity semiconductor laser structure of an embodiment of the present invention is as follows image 3 As shown, it includes: semiconductor laser tube (LD) 1, aspheric collimator lens (AL) 3, grating (GT) 12 and feedback mirror (M) 5.

[0053] image 3 Among them, N represents the normal line of the grating; θi represents the incident angle of the light beam emitted by the semiconductor laser tube 1 and collimated by the collimator lens 3 on the grating; θd represents the diffraction angle of the light beam on the grating. G deno...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com