Measuring device and measuring method of glass fiber water resistance

A glass fiber and measuring device technology, applied in the field of detection, can solve the problems of long time and slowness of normal temperature test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

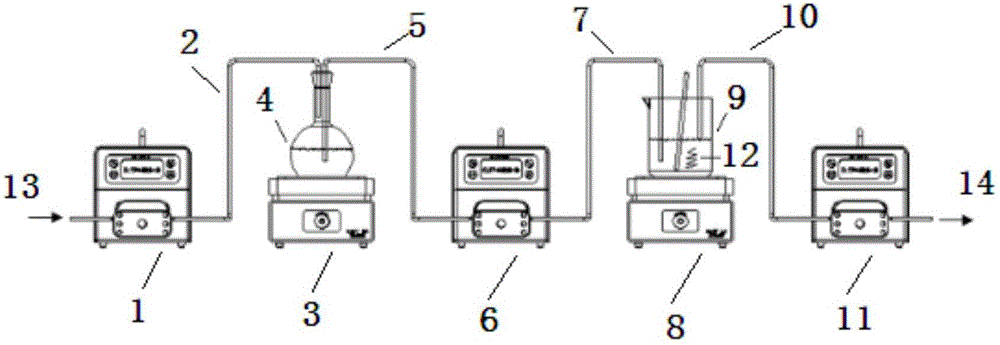

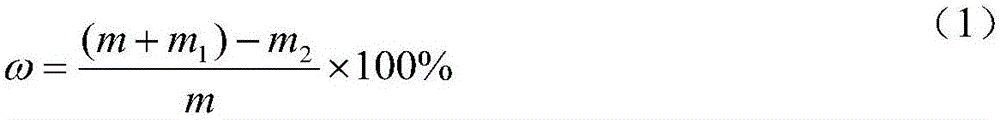

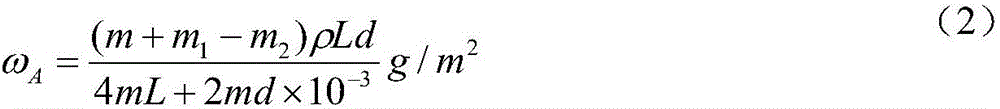

[0063] Determination of water resistance of medium-alkali glass fiber, the medium-alkali glass fiber (CC13-4800) used is produced by Ma'anshan Feilong Fiberglass Composite Material Co., Ltd., and its density is 2.54g / m 3 , a diameter of 15 μm; Type B samples take two parallel samples, the masses are respectively m=1.9283g and m’=2.3293g; the sintered filter with constant weight in step (5) is respectively m 1 =94.7317g,m 1 '=90.3650g; the mass sum of the sintered filter and sample dried to constant weight in step (6) is respectively m 2 =96.6537g,m 2 '=92.6863g; the flow rate of the water in and out of the first peristaltic pump, the second peristaltic pump and the third peristaltic pump is 40mL / min;

[0064] The mass loss rates of two parallel samples taken for type B samples are:

[0065] ω = ( m + m 1 ) - m 2 ...

Embodiment 2

[0074] Determination of water resistance of alkali-free glass fiber, the alkali-free glass fiber (E150-2400) used is produced by Shanghai Leke Pipe Industry Co., Ltd., and its density is 2.6g / m 3 , a diameter of 23.9 μm; Type B samples take two parallel samples, the masses are respectively m=2.3242g and m’=2.0041g; the sintered filter with constant weight in step (5) is respectively m 1 =93.9554g, m 1 '=93.2446g; the mass sum of the sintered filter and sample dried to constant weight in step (6) is respectively m 2 =96.2693g,m 2 '=95.2400g; the flow rate of the water in and out of the first peristaltic pump, the second peristaltic pump and the third peristaltic pump is 30mL / min;

[0075] The mass loss rate of two parallel samples for type B sample is:

[0076] ω = ( m + m 1 ) - m 2 m ...

Embodiment 3

[0086] Determination of water resistance of alkali-resistant glass fiber, the alkali-resistant glass fiber (ARC13-2400) used is produced by Peixian Huaying Glass Fiber Factory, and its density is 2.8g / m 3 , a diameter of 13.2 μm; Type B samples take two parallel samples, the masses are respectively m=2.0254g and m’=2.0013g; the sintered filter with constant weight in step (5) is respectively m 1 =94.7236g, m 1 '=93.9583g; the mass sum of the sintered filter and sample dried to constant weight in step (6) is respectively m 2 =96.7254g, m 2 '=95.9565g; the flow rate of the water in and out of the first peristaltic pump, the second peristaltic pump and the third peristaltic pump is 30mL / min;

[0087] The mass loss rate of two parallel samples for type B sample is:

[0088] ω = ( m + m 1 ) - m 2 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap