Acoustic fluid sensor

A fluid sensor and acoustic technology, applied to scientific instruments, using sound waves/ultrasonic waves/infrasonic waves to analyze fluids, instruments, etc., can solve the problems of poor quality factor and sensitivity performance of acoustic fluid sensors, weak local field strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0102] This embodiment provides a specific embodiment of the acoustic fluid sensor.

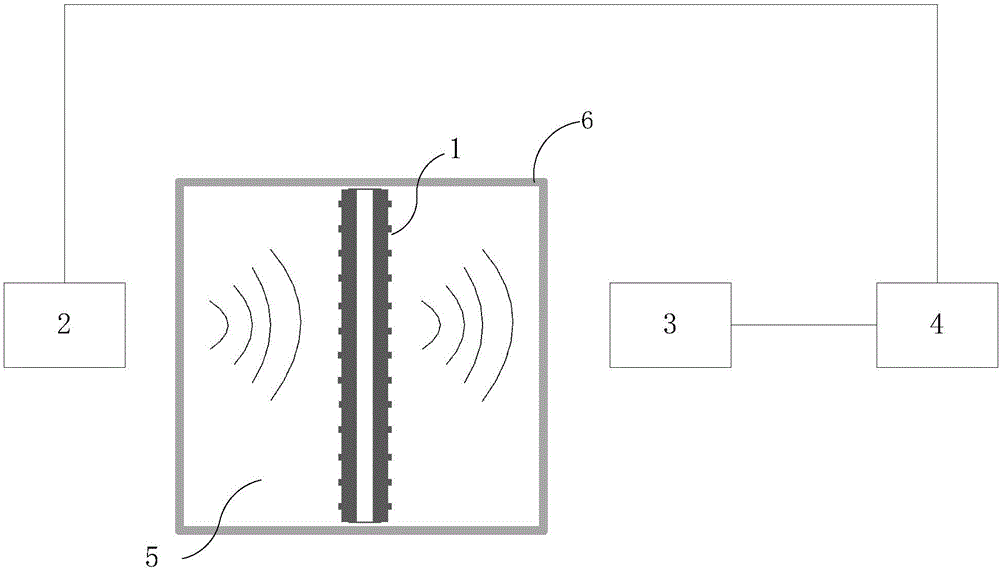

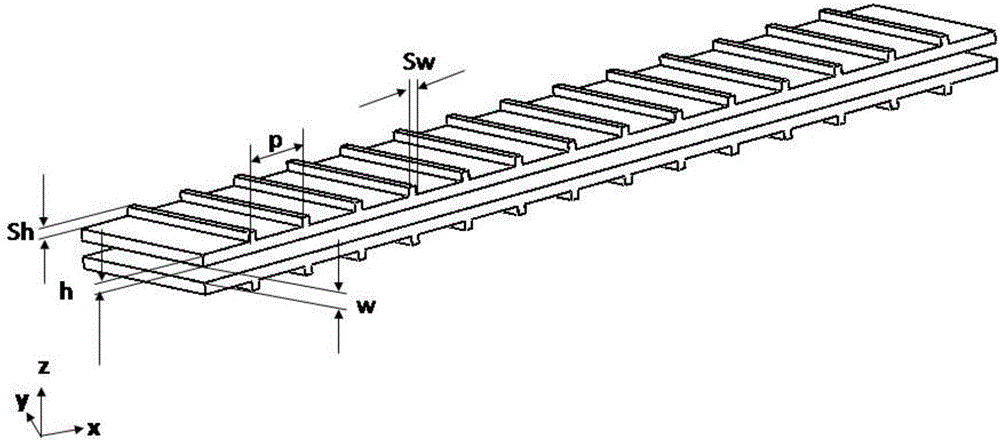

[0103] Figure 4 is a three-dimensional schematic diagram of the acoustic fluid sensor, Figure 5 is the top view of the acoustic fluid sensor.

[0104] like Figure 4 , Figure 5 As shown, the acoustic fluid sensor includes: an experimental container 100 , an ultrasonic emitting device, a slit double-plate acoustic device 300 , an ultrasonic receiving device, and a computing processing device 500 .

[0105] The ultrasonic emitting device includes a signal generator 201 , a power amplifier 202 and an ultrasonic emitting probe 203 .

[0106] The ultrasonic receiving device includes an ultrasonic receiving probe 401 and an analog-to-digital conversion circuit 402 .

[0107] The slotted double-plate acoustic device 300 includes two substrates 301 having the same structure. The shape of the substrate 301 is a rectangle, and a plurality of parallel convex strips 302 are arranged on the front...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonance frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com