A sorting device for thermal insulation microbeads

A particle classification and microbead technology, which is used in solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc. It can solve problems such as non-uniformity, low water absorption, and impact on the quality of insulation boards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

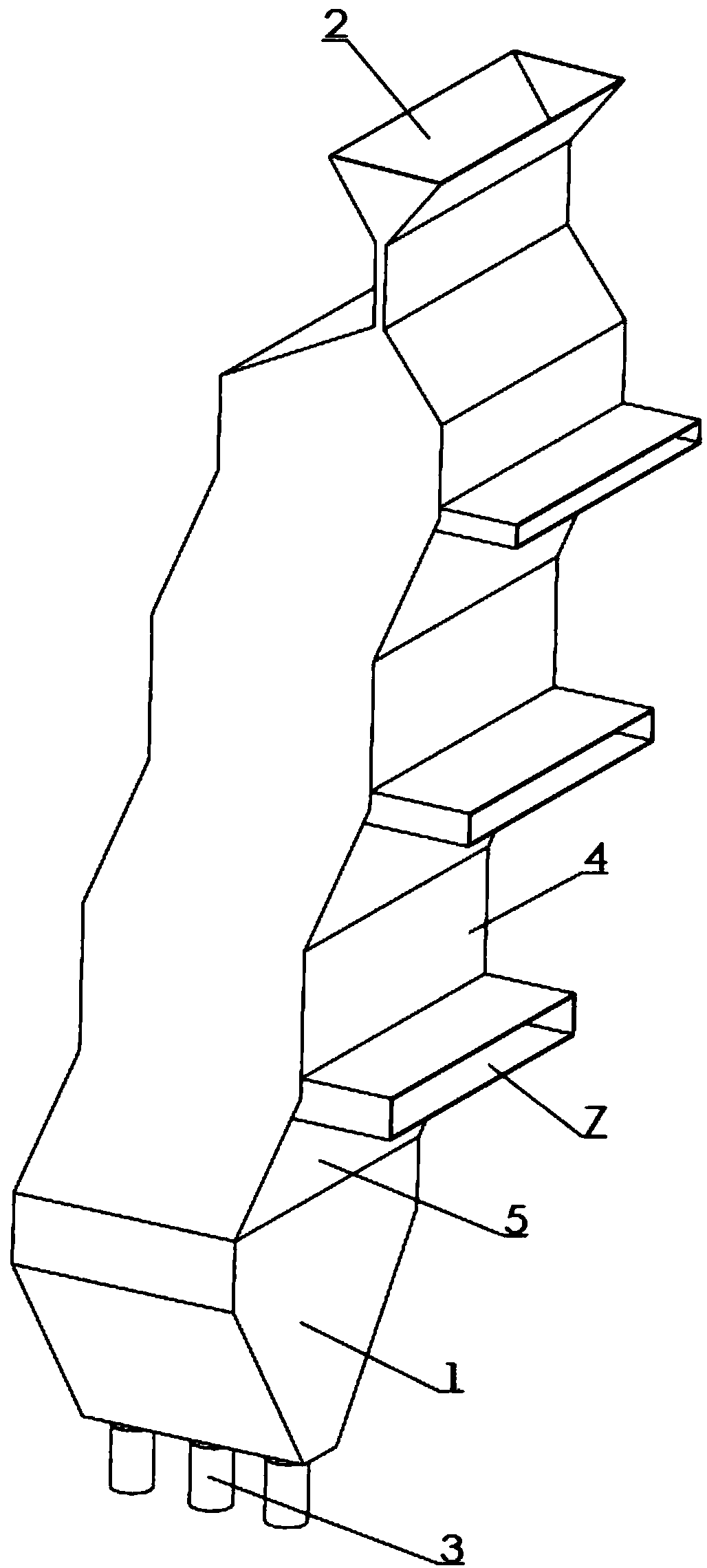

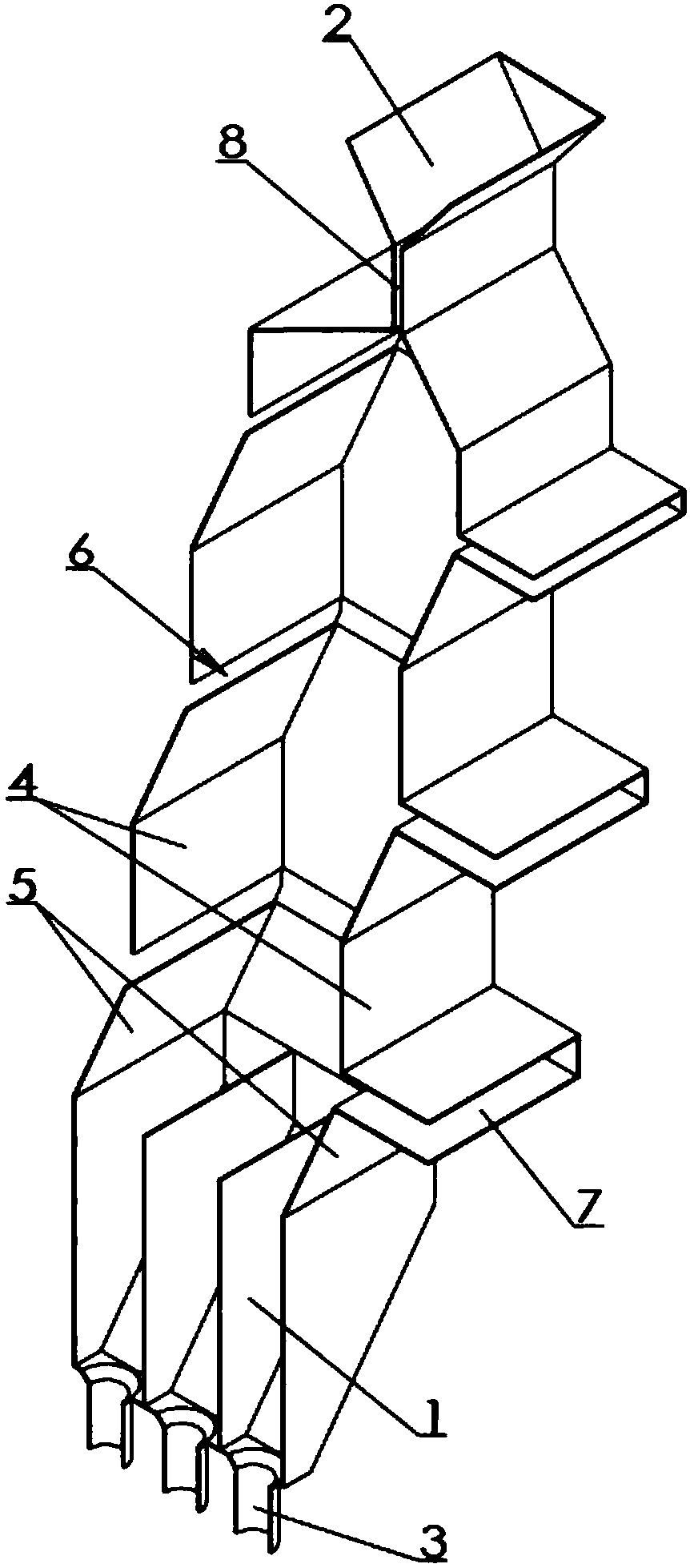

[0013] Examples of the present invention figure 1 , 2 As shown, the thermal insulation microbead particle classification device is provided with a receiving hopper 1, a grading flow channel and a falling hopper 2. The horizontal section of the receiving hopper is rectangular, and the open bottom of the upper part of the receiving hopper is connected with a discharge pipe 3. The receiving hopper At least two, and three in this embodiment. The actual number can be determined according to the different sizes of raw materials. Each hopper is aligned front and rear and arranged in the left and right directions to form a hopper group. The left and right width of each hopper is smaller than the front and rear length. The graded flow channel is provided with at least two levels of direction-changing flow channels arranged up and down. This embodiment is three-level, and the number can be adjusted more specifically. The vertical side walls before and after the direction-changing flow c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com