Double-station automatic belt head mechanism

It is an automatic and belted technology, which is applied to tires, other household appliances, household appliances, etc. It can solve the problems of high cost of traveler, influence on use, and low efficiency, so as to reduce labor intensity, improve automation level, and protect from damage. damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

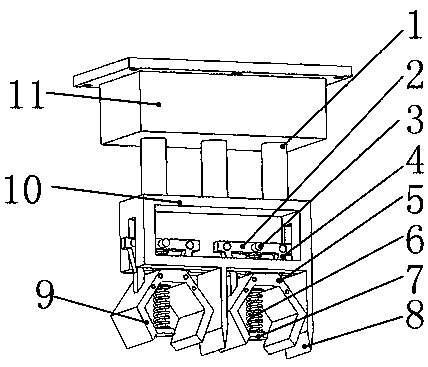

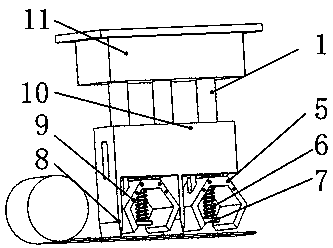

[0013] The specific structure and implementation mode of the present utility model will be further described below in conjunction with the accompanying drawings.

[0014] The structural composition of the present utility model is as figure 1 and figure 2 shown. The double-station automatic belt head mechanism consists of a cylinder (1), a swing rod (2), a link pin (3), a connecting rod (4), a splint body (5), a return spring (6), and a return rod (7) , Cutter (8), clamping plate (9), clamping plate support frame (10), cylinder box (11) forms.

[0015] Bolt holes are left above the cylinder box (11) to connect with the external support, the cylinder box (11) and the cylinder (1) form the power source of the mechanism, and the cylinder (1) can be pushed to move vertically back and forth through the pneumatic device. The cylinder (1) is connected to the splint support frame (10), and the swing rod (2) is installed on the splint support frame (10), and the two swing rods (2) a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com