Eccentric bag breaking machine

A bag breaking machine and eccentric technology, applied in packaging, cutting and unsealing, transportation and packaging, etc., can solve the problems affecting the normal operation of the bag breaking machine, damage to the bag breaking blade, and reduced bag breaking efficiency, so as to ensure the working efficiency of bag breaking , reduce the chance of contact, the effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

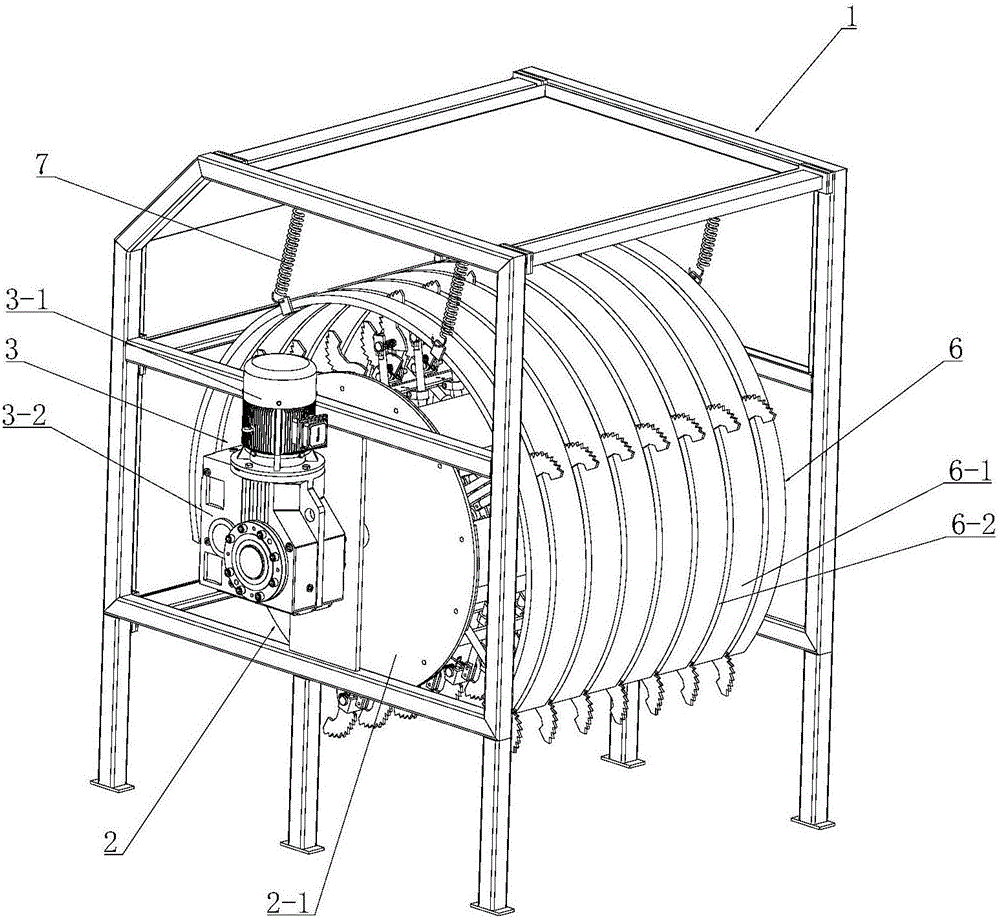

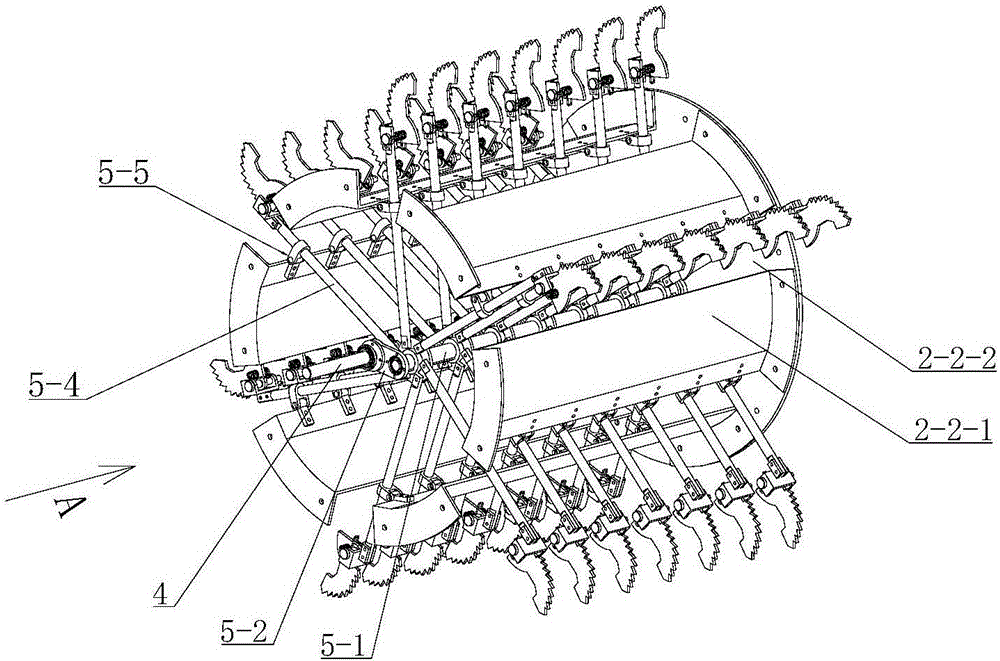

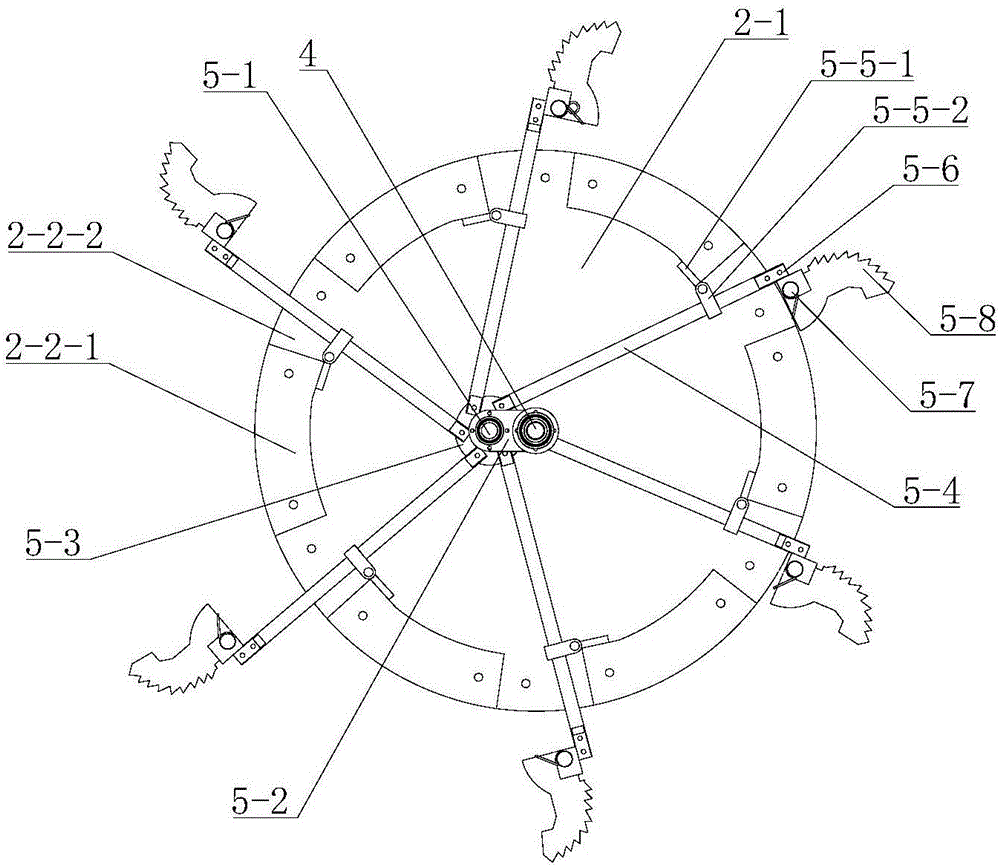

[0024] See Figure 1-7 , an eccentric bag breaking machine, mainly consists of the following parts:

[0025] The frame body 1 is included, and the frame body adopts a frame structure welded by profiles.

[0026] Including a roller 2, the roller is arranged in the frame body, the roller is composed of end plates 2-1 located at both ends and a cylinder 2-2 arranged between the two end plates, and the cylinder is composed of It is surrounded by several arc-shaped column panels 2-2-1 arranged in the same direction, and an opening 2-2-2 is left between every two adjacent column panels. The central positions of the two end plates are provided with connecting sleeves 2-1-1. Specifically, the connecting sleeves can be integrally formed with the end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com