Shunting conveying device and method

A technology of shunt conveying and conveyor belt, applied in the direction of conveyor objects, transportation and packaging, can solve the problem of low production efficiency of single-line conveying, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

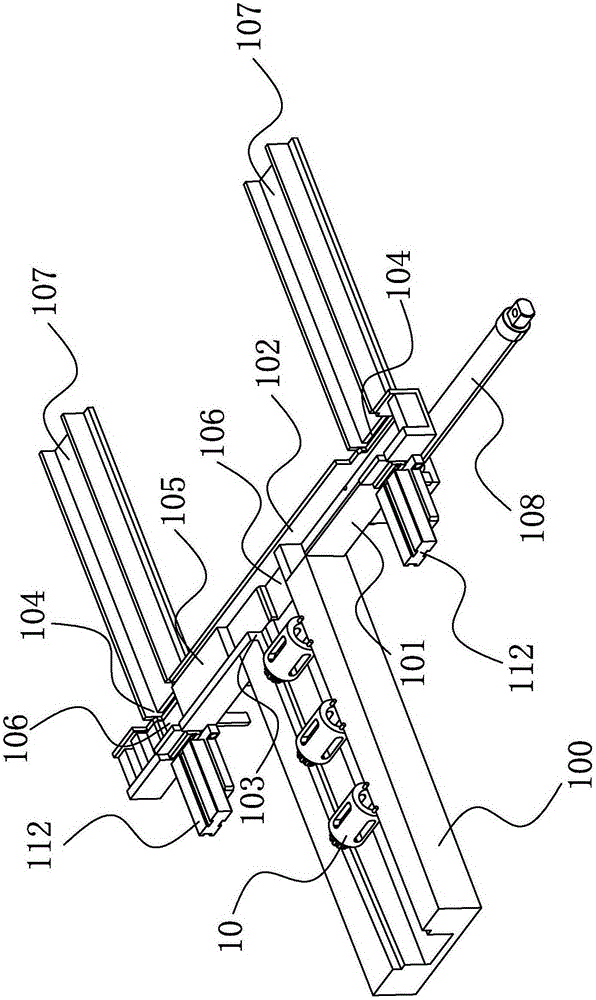

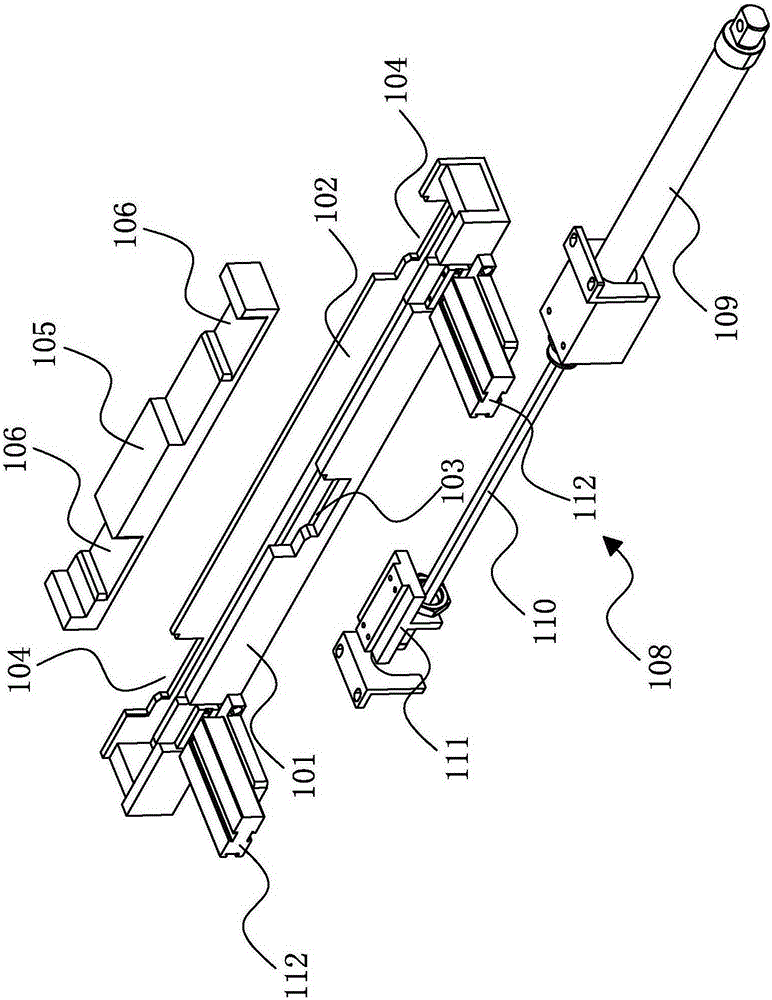

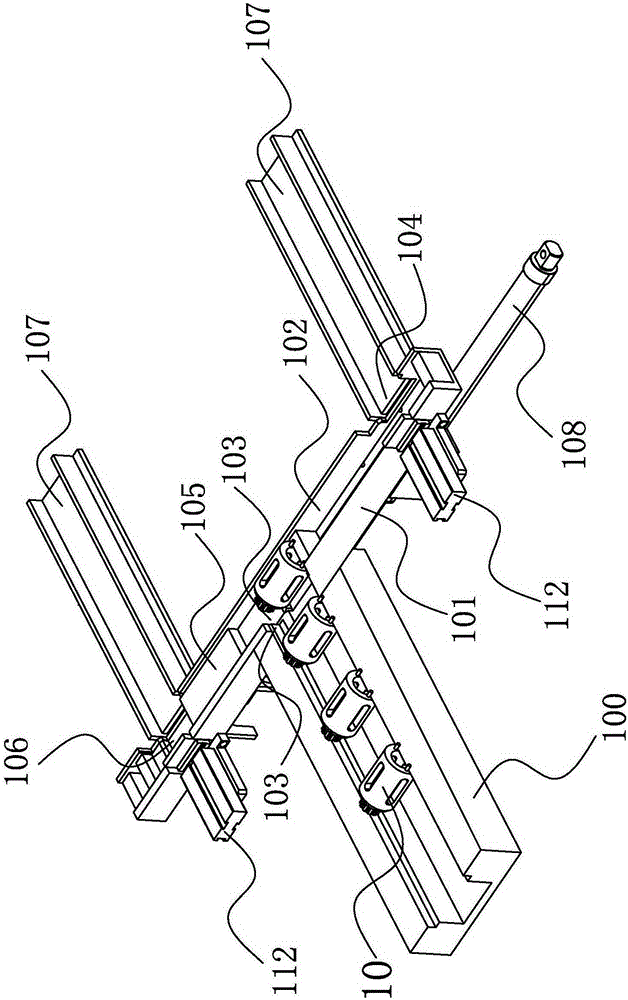

[0038] see figure 1 and figure 2 shown, where figure 1 A structural schematic diagram of a preferred embodiment of the material distribution conveying device of the present invention is shown, figure 2 A partial exploded schematic diagram of a preferred embodiment of the material distribution conveying device of the present invention is shown.

[0039] In a preferred embodiment, the present invention provides a shunt delivery device, which includes:

[0040] A material tank 100, in which several materials 10 to be conveyed are placed side by side;

[0041] The base 101 is provided with a slide groove 102, one side of the slide groove 102 has a feed port 103, the feed port 103 is connected to one end of the material tank 100, and the other side of the slide groove 102 has two discharge ports 104;

[0042] The slider 105 is arranged in the sliding groove 102. The slider 105 has two clamping parts 106 for clamping the material 10. When one of the clamping parts 106 correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com