Pneumatic control mechanism and control method for roller groove ironing connection

A technology of pneumatic control and roller groove, which is applied in the field of flat fabric ironing, and can solve the problems of single-group equipment maintenance and single-group equipment that cannot be used and operated independently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

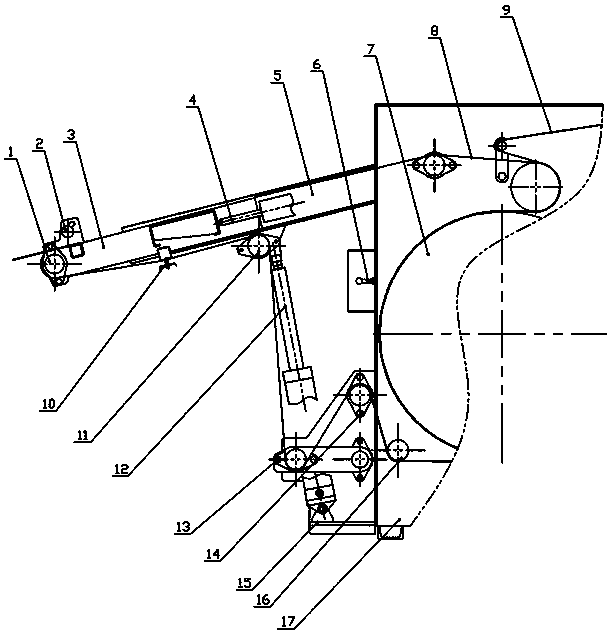

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0023] see figure 1 , the present invention provides a pneumatic control mechanism for the connection of roller groove ironing, which is mainly composed of a main support connecting frame 5, a cloth output shaft 1, a cloth pressing shaft 2, an ironing roller 7, a driving ironing belt 8, and a guide belt 9. Roll frame 17 after roller ironing, telescopic support 3, telescopic cylinder 4, control handle 6, spacer pin 10, guide shaft I 11, lifting cylinder 12, anti-drop swing bar 13, guide shaft II 14, lifting cylinder Bracket 15 and guide shaft III 16 form.

[0024] The front end of the main support connecting frame 5 is provided with a telescopic support 3, and the telescopic support 3 is connected to the telescopic cylinder 4, and the lower air inlet of the telescopic cylinder 4 is provided with an air inlet valve. The bottom of the main support adap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com