Rotary compressor

A rotary compressor and compressor technology, applied to rotary piston/oscillating piston pump components, mechanical equipment, machines/engines, etc., can solve the problem of poor air suction at 90' of the pump body and affect the performance of the compressor, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

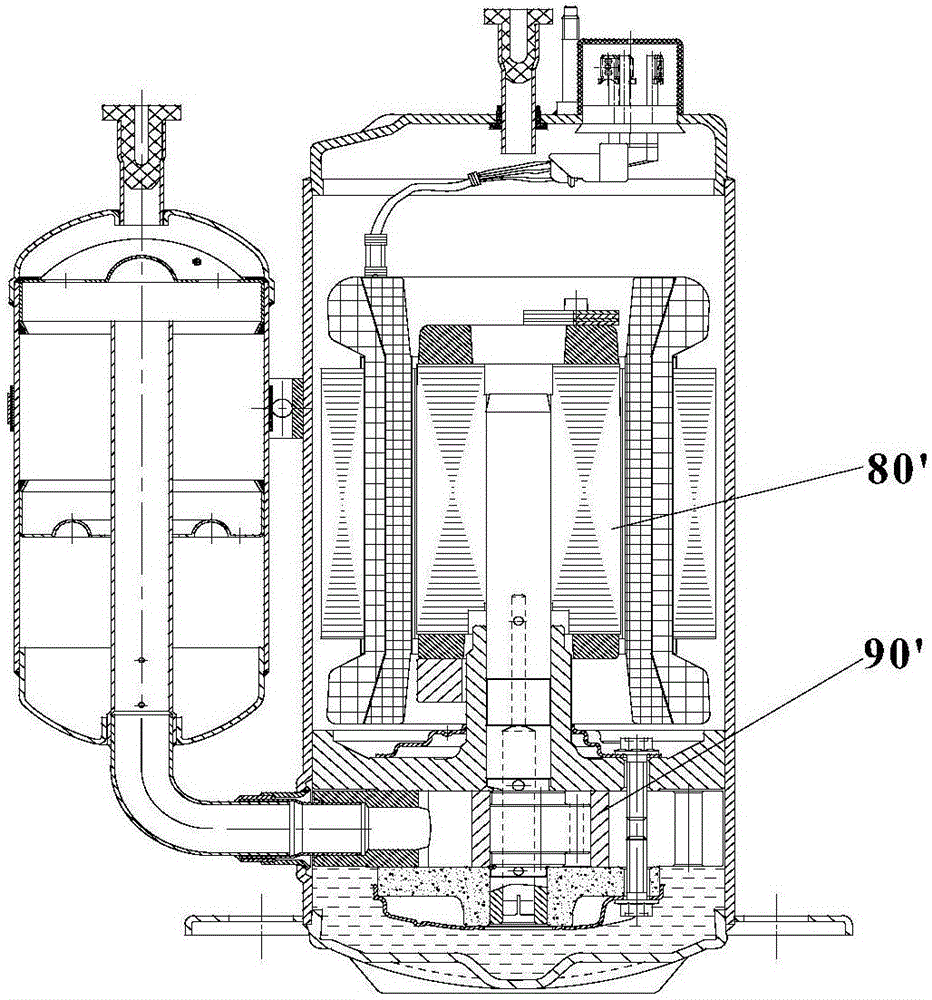

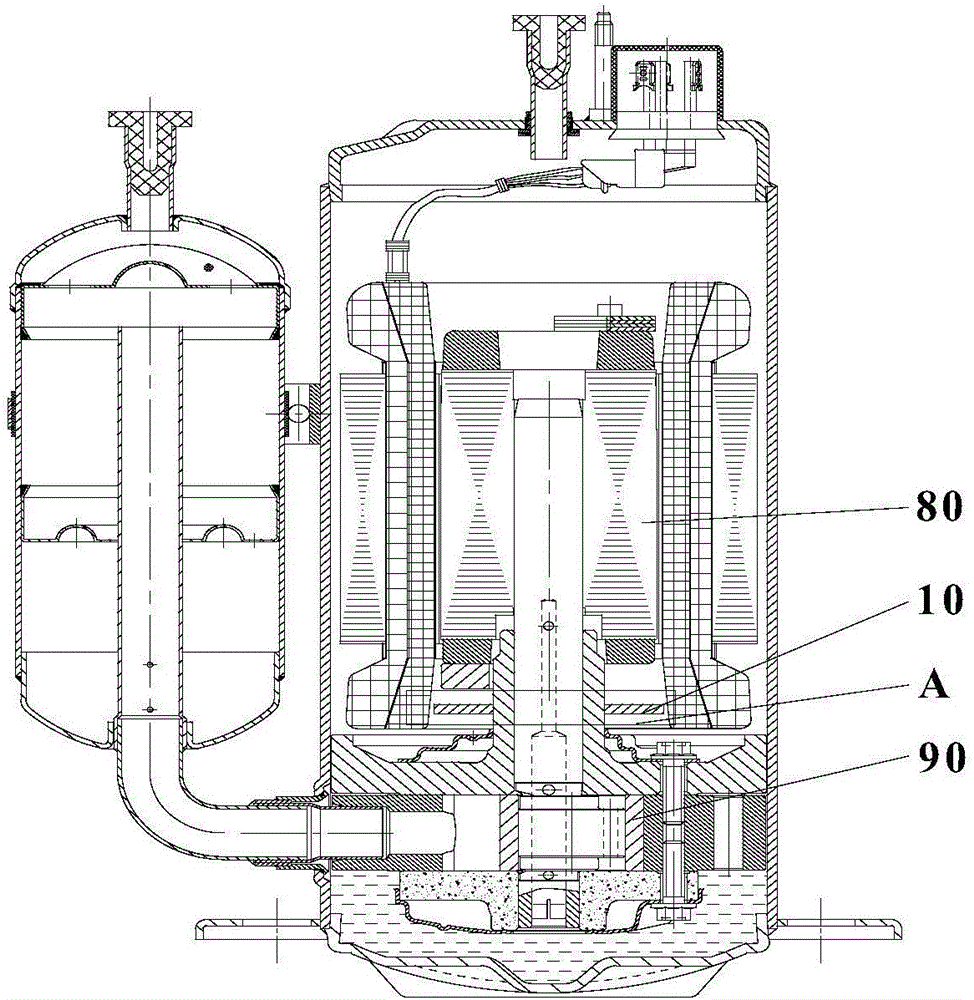

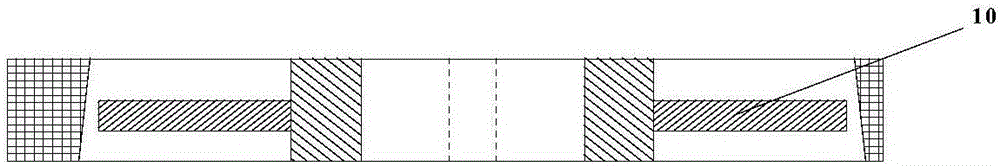

[0045] like figure 2 and image 3 As shown, the embodiment of the present invention provides a rotary compressor, including a rotor 80 and a pump body 90, the rotary compressor also includes a partition 10 for separating the rotor 80 and the pump body 90, and the partition 10 is arranged on the rotor 80 and pump body 90 between.

[0046] The separator 10 is set to separate the rotor 80 from the pump body 90, which can prevent the impact of the exhaust gas from the pump body 90 on the rotor 80, prevent the exhaust gas from the pump body 90 from impacting the rotor 80, and avoid the axial runout of the crankshaft and the rotor 80. Thereby reducing or avoiding the generation of noise and achieving the purpose of eliminating abnormal sound. The above partition 10 can be made of metal o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com