Treatment method for high-cavitation peripheral pump impeller

A treatment method, the technology of the vortex pump, which is applied to the components of the pumping device for elastic fluid, pumps, pump components, etc., can solve the problems of reducing the service life of the impeller, uneven flow velocity distribution, and potential safety hazards, and achieve the purpose of reducing impact , Improve cavitation performance, weaken the effect of mutual impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

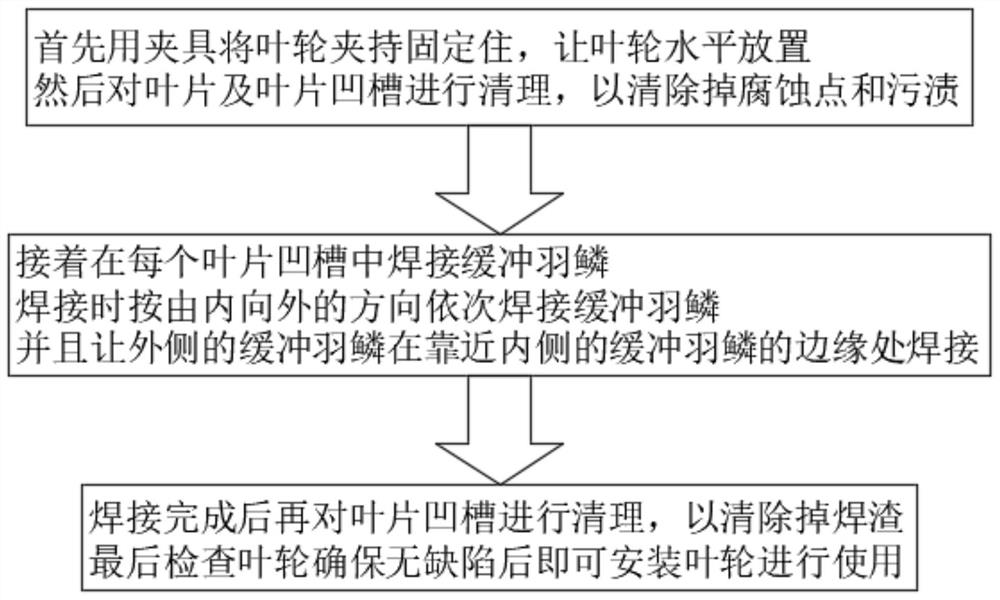

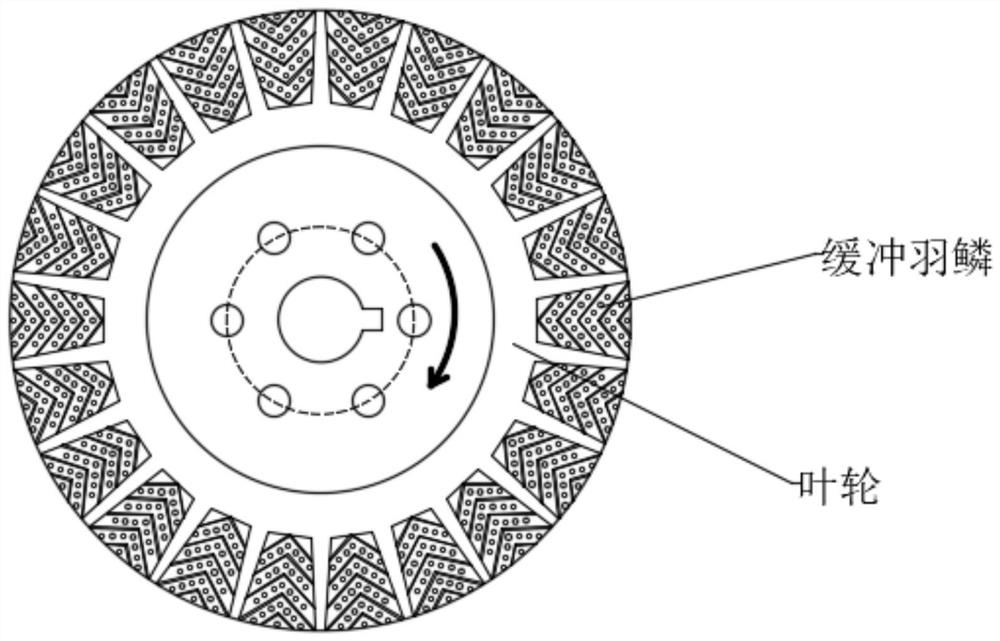

[0048] see Figure 1-8 , a high cavitation vortex pump impeller treatment method, see Figure 1-3 and Figure 5 , including the following processing steps:

[0049] S1, first clamp and fix the impeller with a clamp, let the impeller be placed horizontally, and then clean the blade and blade groove to remove corrosion points and stains;

[0050] S2, then weld the buffer feather scales in each blade groove, weld the buffer feather scales sequentially from the inside to the outside during welding, and let the outer buffer feather scales be welded near the edge of the inner buffer feather scales;

[0051] S3, after the welding is completed, clean the groove of the blade to remove the welding slag, and finally check the impeller to ensure that there is no defect before installing the impeller for use;

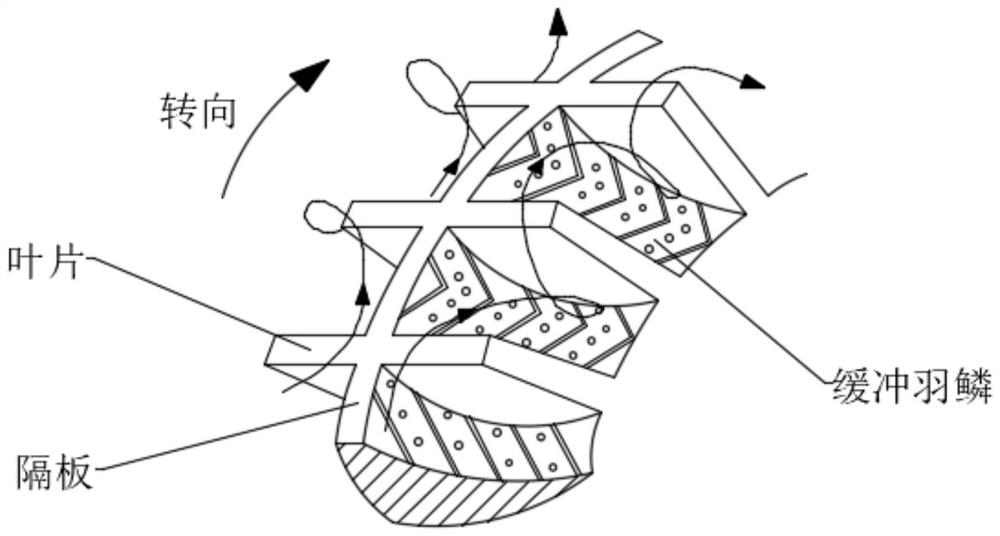

[0052] see Figure 2-4 , the buffer feather scale in the S2 step is a V-shaped structure, which can guide the liquid entering and leaving the blade groove, weaken the mutual imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com