Hydraulic design method of axial-flow type heavy metal pump

A hydraulic design, heavy metal technology, applied in axial flow pumps, components of pumping devices for elastic fluids, non-variable pumps, etc., can solve the problems of no heavy metal pumps, less research on heavy metal pumps, etc., and achieve reliable operation , the effect of good hydraulic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

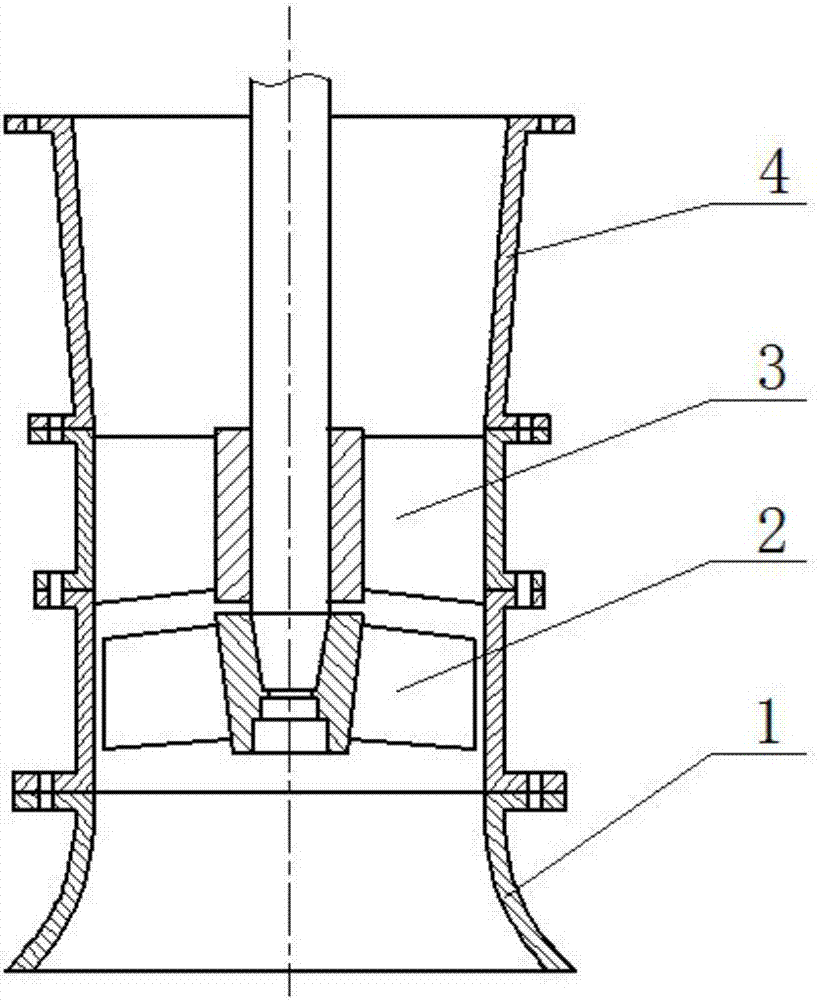

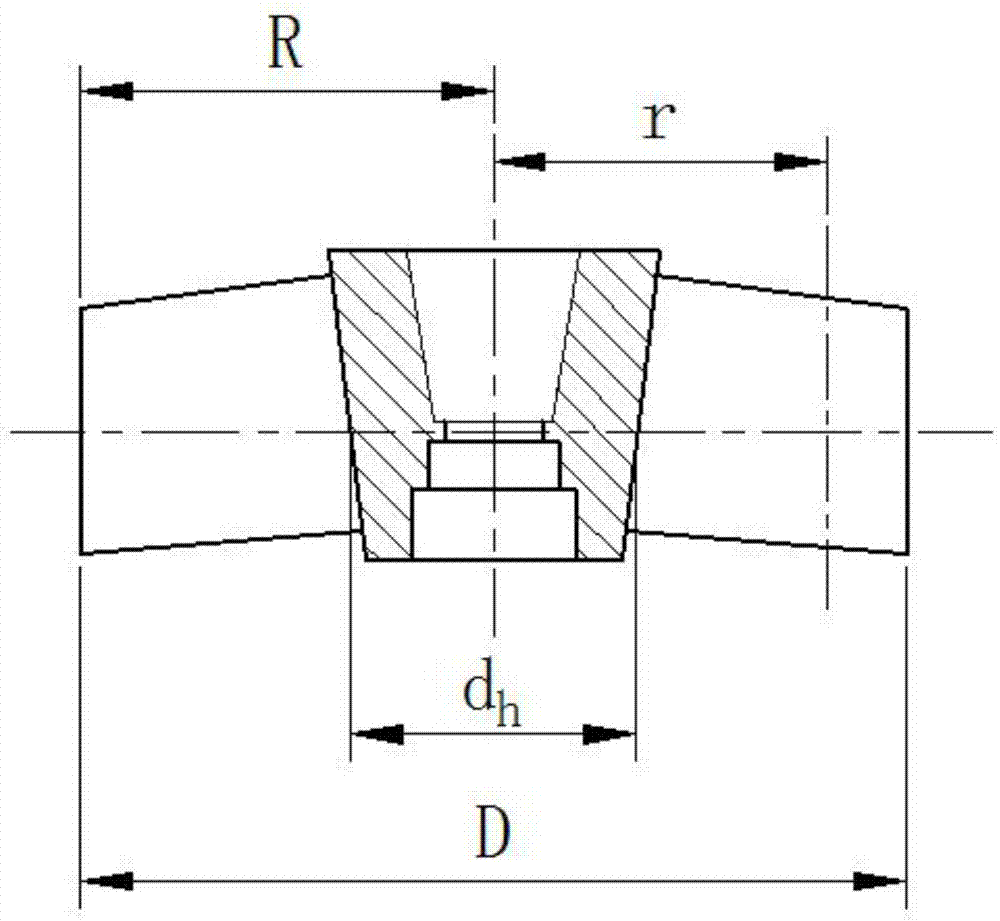

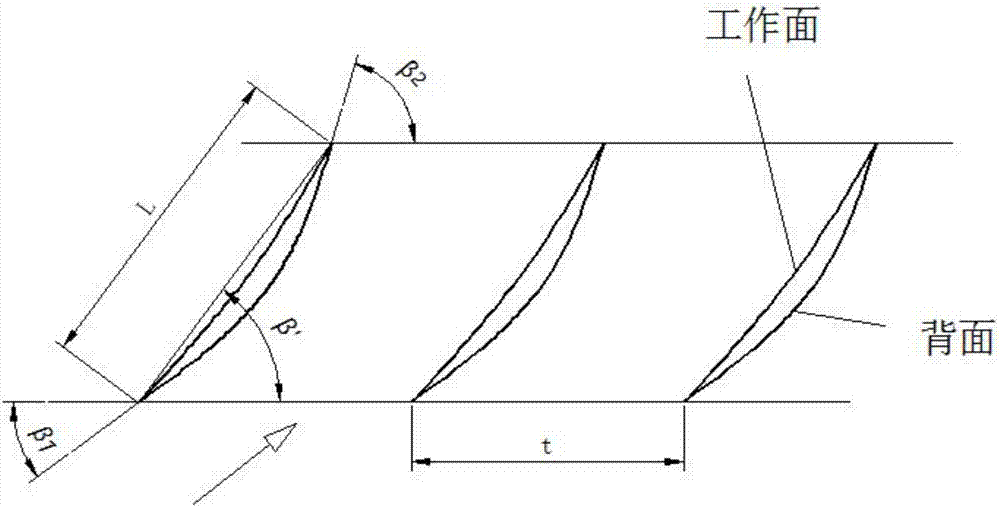

[0052] Figure 1 to Figure 5 It is a schematic structural diagram of an embodiment of the present invention and a schematic cross-sectional diagram of each flow-passing component. The invention provides a hydraulic design method of an axial-flow heavy metal pump. The axial-flow heavy metal pump works under extreme high-temperature conditions, and the conveying medium is high-temperature liquid metal. The main flow-through components are composed of a suction chamber (1), an impeller ( 2), the guide vane (3) and the diffuser tube (4) are composed of four parts. The structural parameters of the heavy metal axial flow pump include the outer diameter of the impeller D, the hub ratio, the airfoil placement angle, the leaf density, the number of guide vane blades, The cone angle of the guide vane body, the distance between the inlet side of the guide vane and the outlet side of the impeller, the length of the diffuser tube and the divergence angle of the diffuser tube are used for h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com