Tin liquid detection, sumplementation method and device

A detection device and tin liquid technology, applied in auxiliary devices, metal processing equipment, manufacturing tools, etc., can solve the problems of unqualified tin dipping quality, difficulty in controlling the melting amount of tin rods, limited machines, etc., and achieve tin dipping quality Improvement, supplementary accuracy increase, and the effect of expanding the number of machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

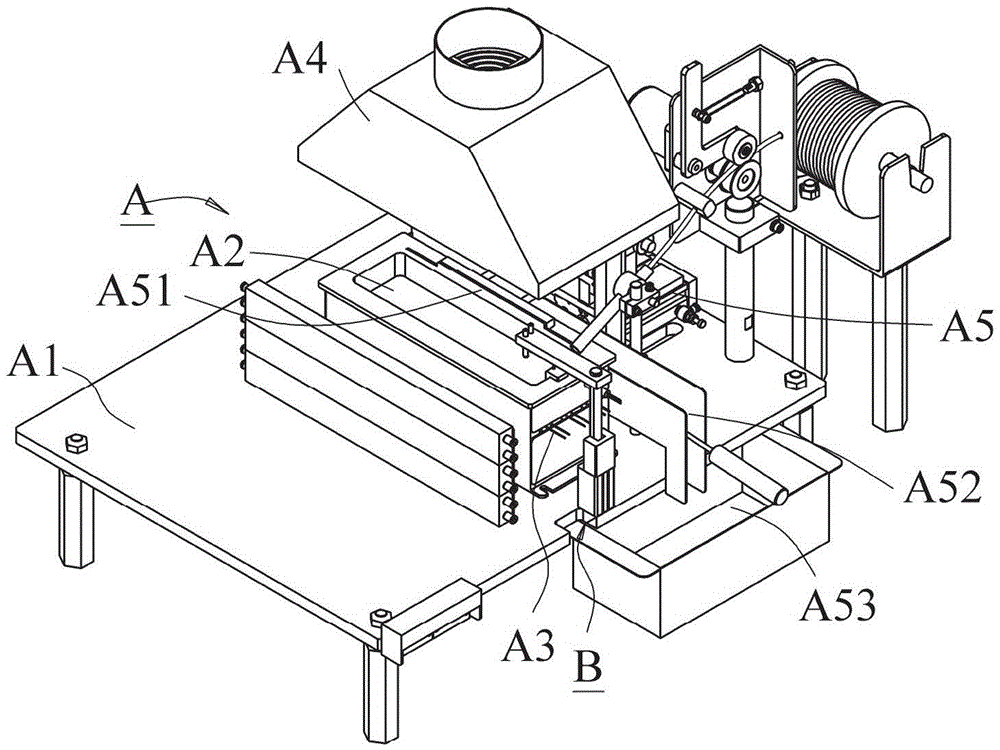

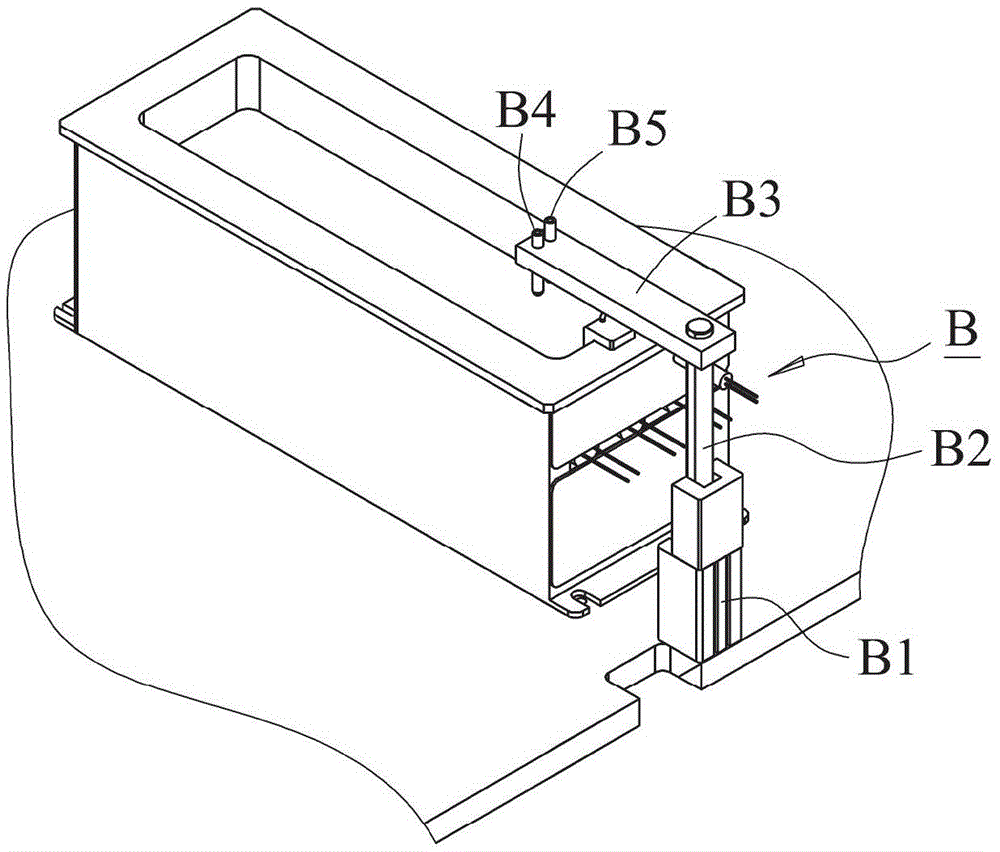

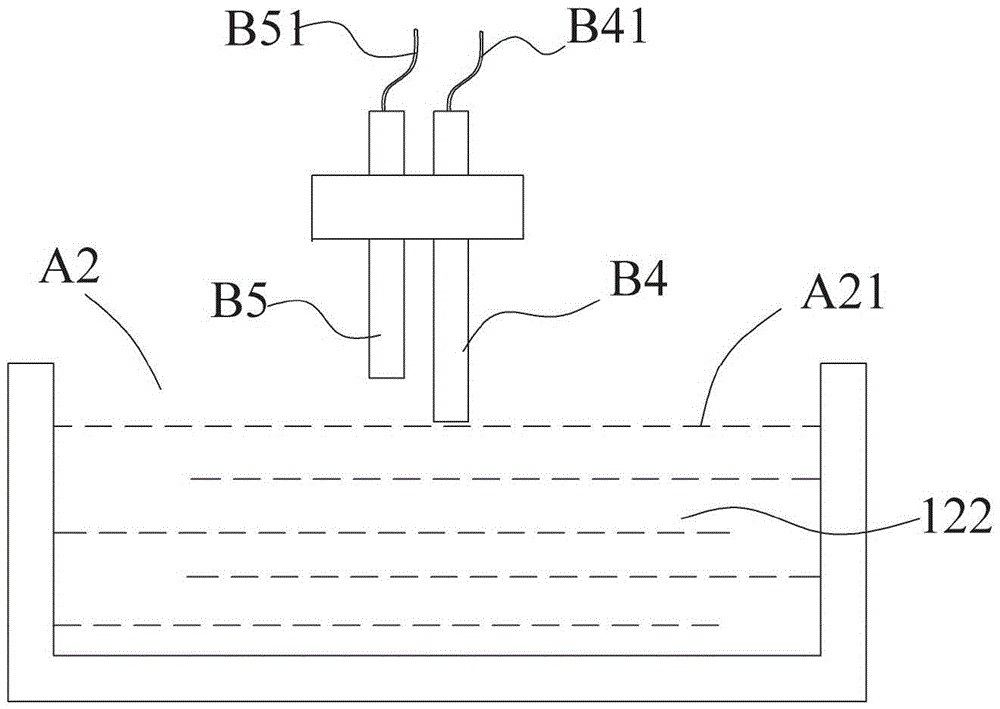

[0042] see figure 1 , 2 The liquid tin detection and replenishment method and device in the embodiment of the present invention can be taken as an example of the liquid tin detection and replenishment device in the figure, including:

[0043] A tin furnace A, roughly in the shape of a rectangle, is set on a base A1, in which there is a furnace chamber A2 to hold liquid tin, and a heater A3 is provided under the furnace chamber A2 to heat the liquid tin in the furnace chamber A2. Heating, an exhaust device A4 is provided above the tin furnace A to discharge the gas evaporated from the flux during the tin dipping process, and a scraping device A5 is installed on one side of the long side of the rectangle of the tin furnace A, and a scraper A51 is used to control the furnace chamber A2 The oxide layer on the surface of the inner tin liquid is scraped and stripped to move back and forth, so as to scrape the oxide layer into the guide groove A52 on the A side of the tin furnace, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com