Crack-free electronic beam welding method for titanium metal material and stainless steel

A technology of electron beam welding and titanium metal, which is applied in the direction of electron beam welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of easy cracks, low strength, and poor toughness of titanium metal materials and stainless steel, and achieve improved toughness, Improve the strength and toughness, reduce the effect of thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

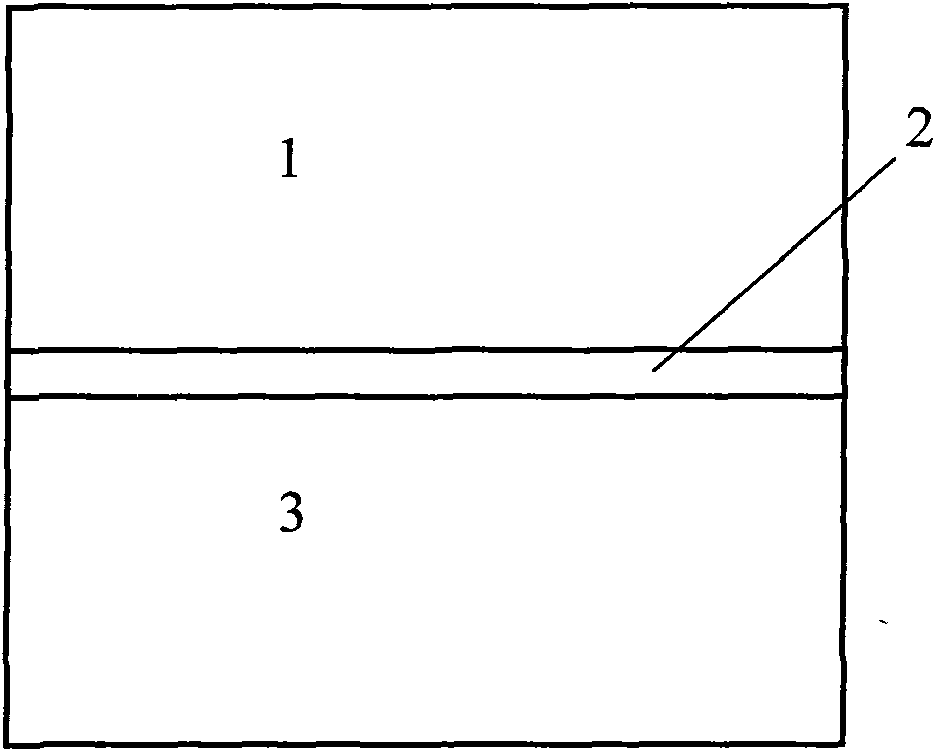

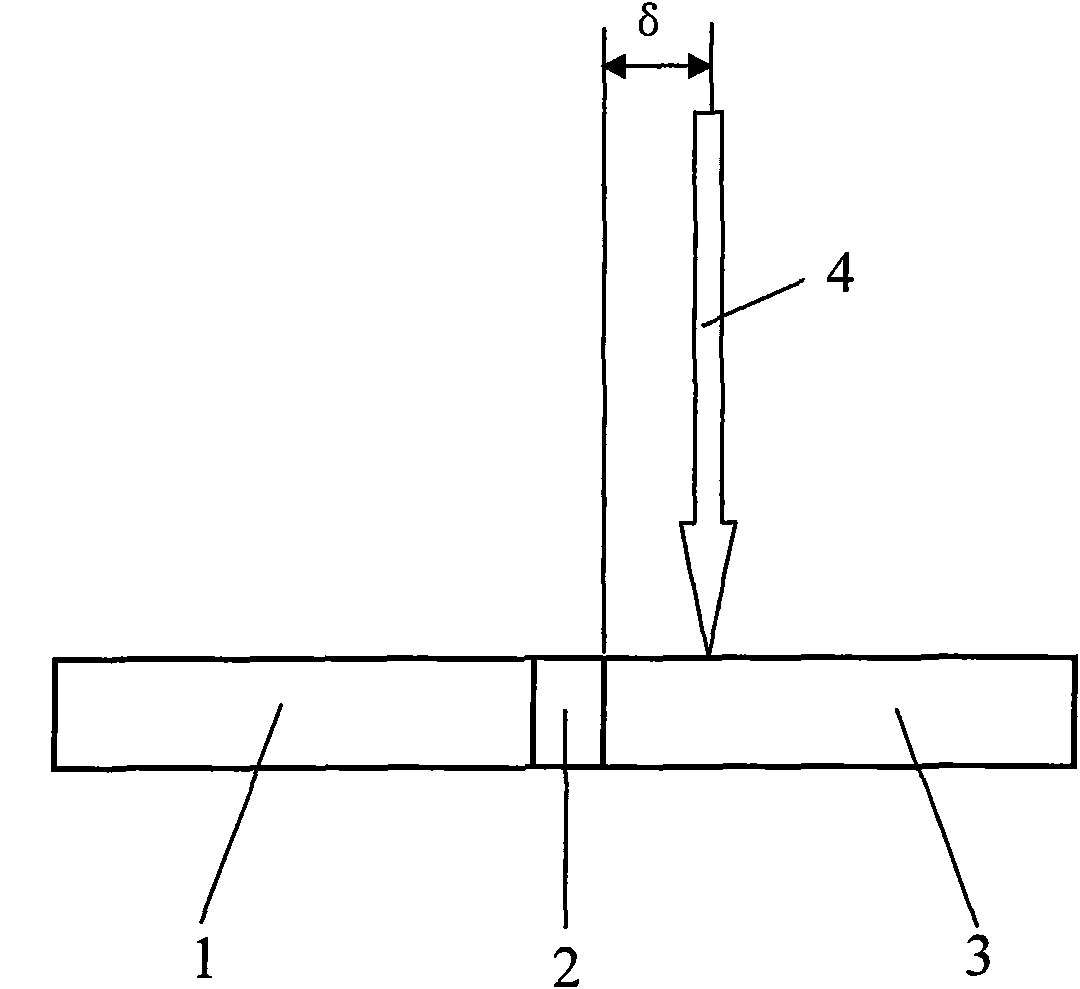

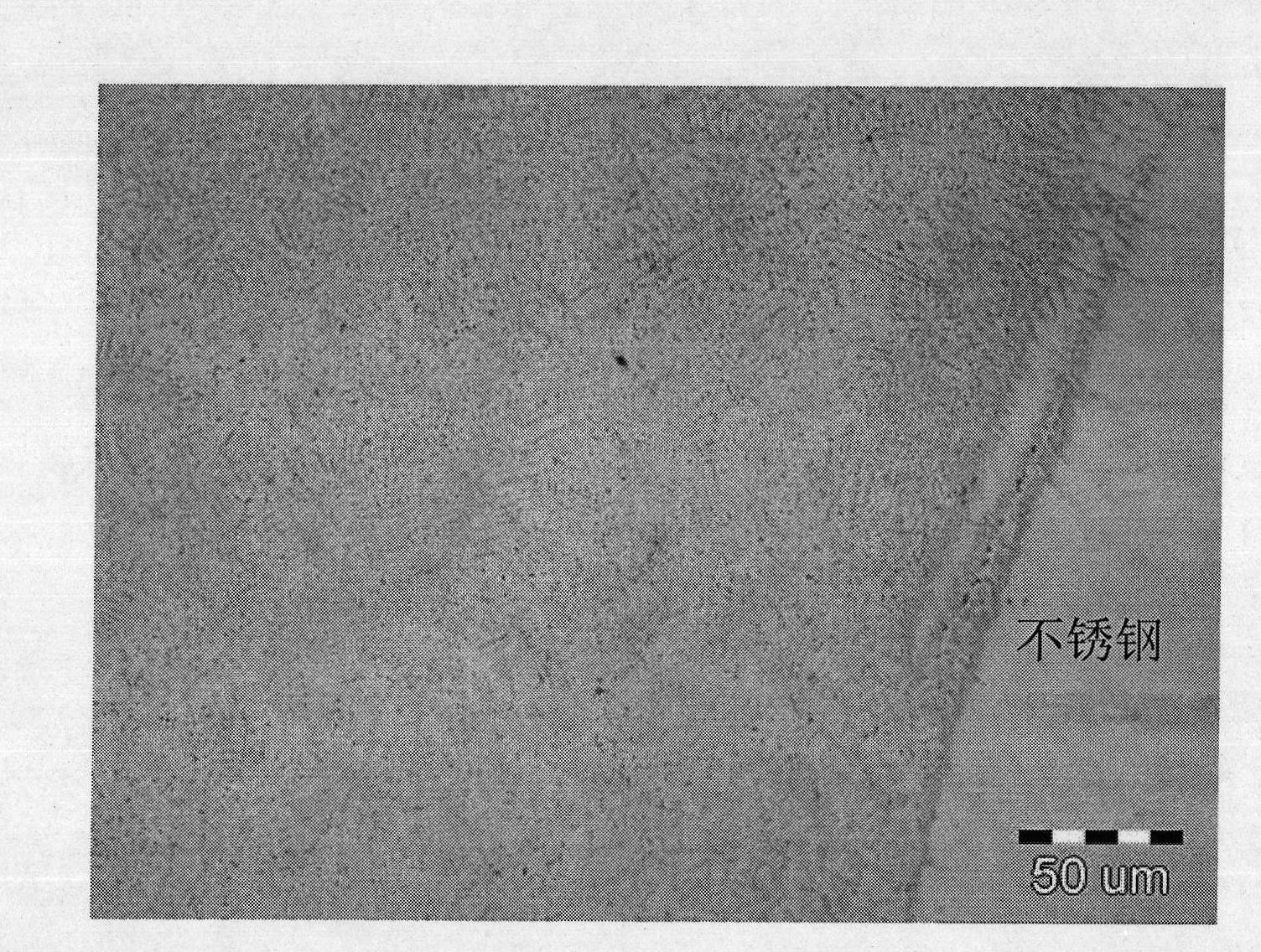

[0012] Specific implementation mode one: (see figure 1 , figure 2 ) The welding method of the present embodiment is realized according to the following steps: One, placing the copper plate 2 with a thickness of 0.5 mm to 2.0 mm and a purity >= 99.95% (quality) as an intermediate layer between the titanium metal material plate 1 to be welded and the stainless steel plate 3 2. Fix the parts to be welded rigidly on the fixture, and use tungsten inert gas welding to fix them by spot welding at both ends, so that the middle layer copper plate 2 is respectively connected to the butt joint surfaces of the titanium metal material plate 1 and the stainless steel plate 3 The gap is 0.05mm ~ 0.25mm; 3. Put the fixed parts to be welded in acetone for 5min ~ 30min ultrasonic cleaning, then pickle, and then dry; The parts are fixed in the electron beam welding vacuum chamber for electron beam welding, and the vacuum degree of the vacuum chamber is 10 -5 Pa~10 -4 Pa, when welding, the el...

specific Embodiment approach 2

[0013] Specific implementation mode two: (see figure 1 , figure 2 ) The difference between this embodiment and the specific embodiment 1 is: the thickness of the copper plate 2 in step 1 is 0.7mm-1.5mm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0014] Specific implementation mode three: (see figure 1 , figure 2 ) The difference between this embodiment and the first embodiment is: the thickness of the copper plate 2 in the first step is 1.0 mm. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com