Welded synthetic resin body, and production method therefor

A technology of synthetic resin and manufacturing method, applied in other household appliances, household components, applications, etc., can solve the problems of tumor protrusion, outstanding performance, impact, etc., and achieve the purpose of inhibiting tumor protrusion into the oil circuit and inhibiting tumor protrusion to the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

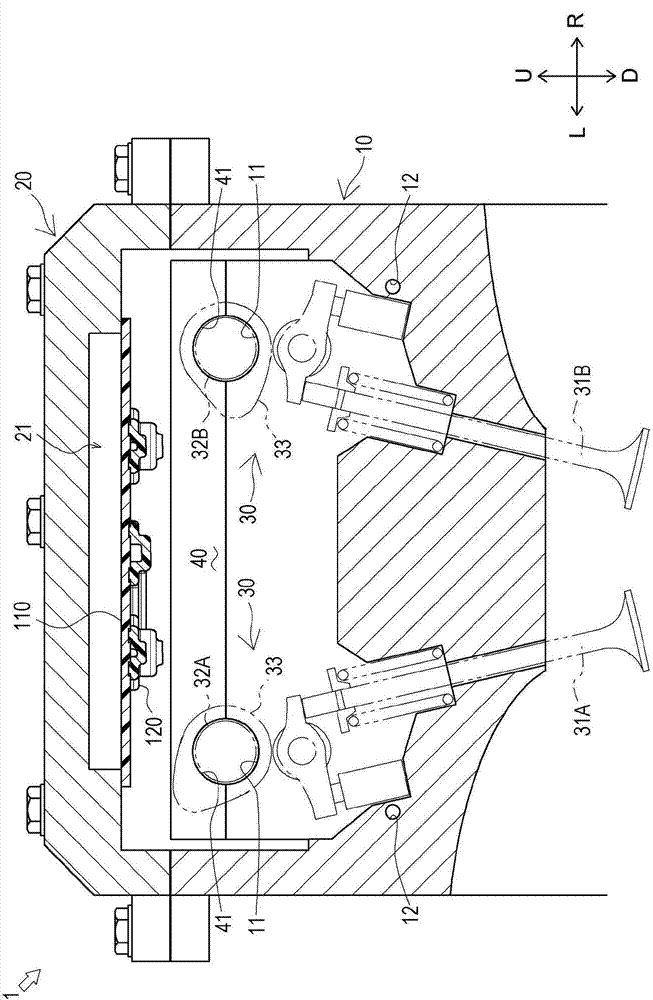

[0042] In the following, the directions indicated by arrow U, arrow D, arrow F, arrow B, arrow L and arrow R in the figure are respectively defined as upper direction, lower direction, front direction, rear direction, left direction and right direction to carry out illustrate.

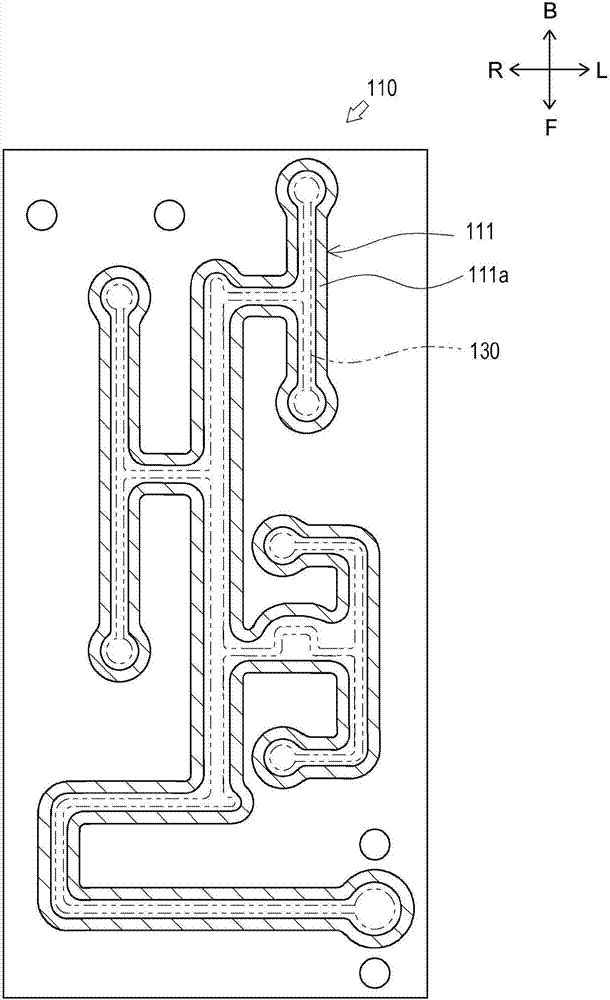

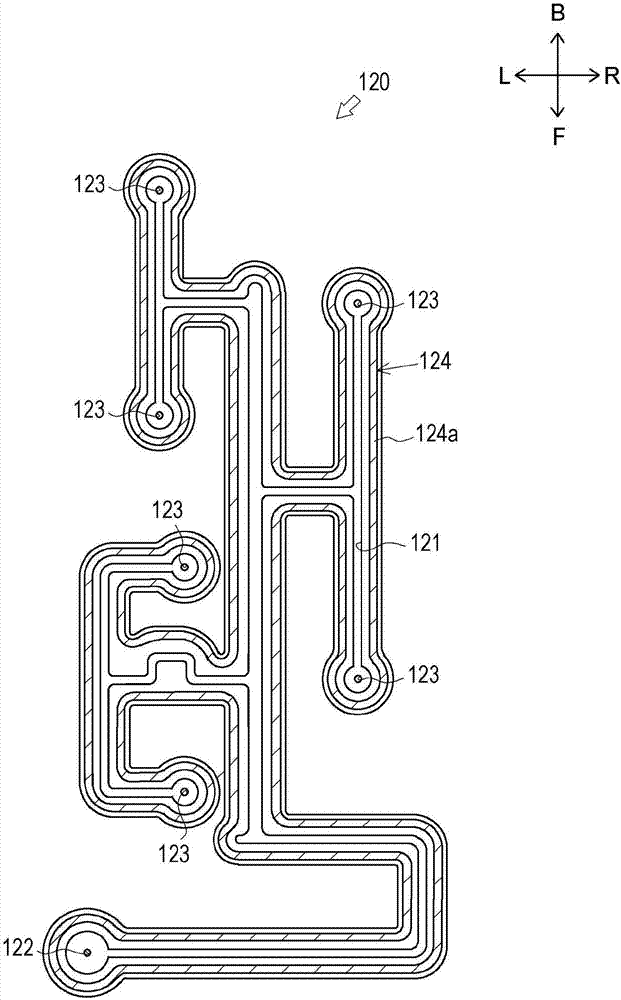

[0043] first use figure 1 , the configuration of the engine 1 including the baffle plate 110 and the oil passage forming member 120 according to one embodiment of the present invention will be described.

[0044] The engine 1 of the present embodiment includes valve mechanisms 30 , which will be described later, on the intake side and the exhaust side, respectively. Since the structure of the valve mechanism 30 is substantially the same on the suction side and the exhaust side, in the following, for the convenience of description, the structure on the exhaust side ( figure 1 The structure shown on the left side) will be described, and the structure on the suction side will be omitted appropriately ( ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com