Copper processing horizontal-continuous-casting automatic feeder

An automatic feeding device and horizontal continuous casting technology, applied in the field of copper processing horizontal continuous casting, can solve the problems of copper water bursting safety, static pressure instability, liquid level instability, etc., to ensure liquid level, avoid manual operation, structure well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

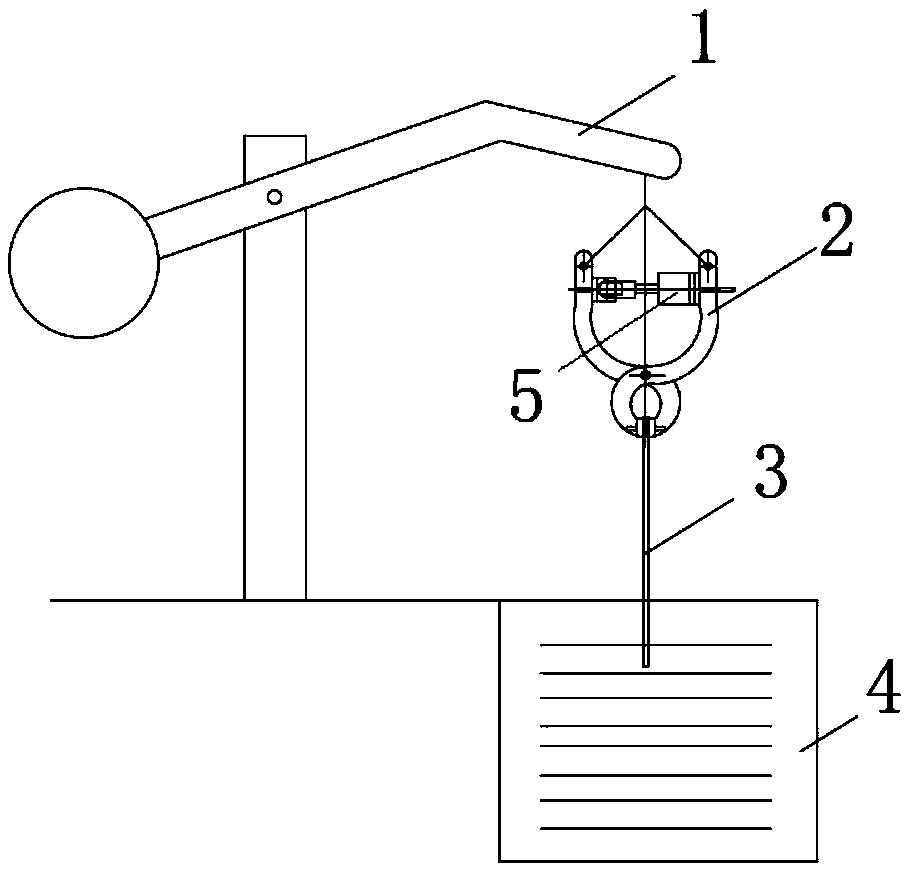

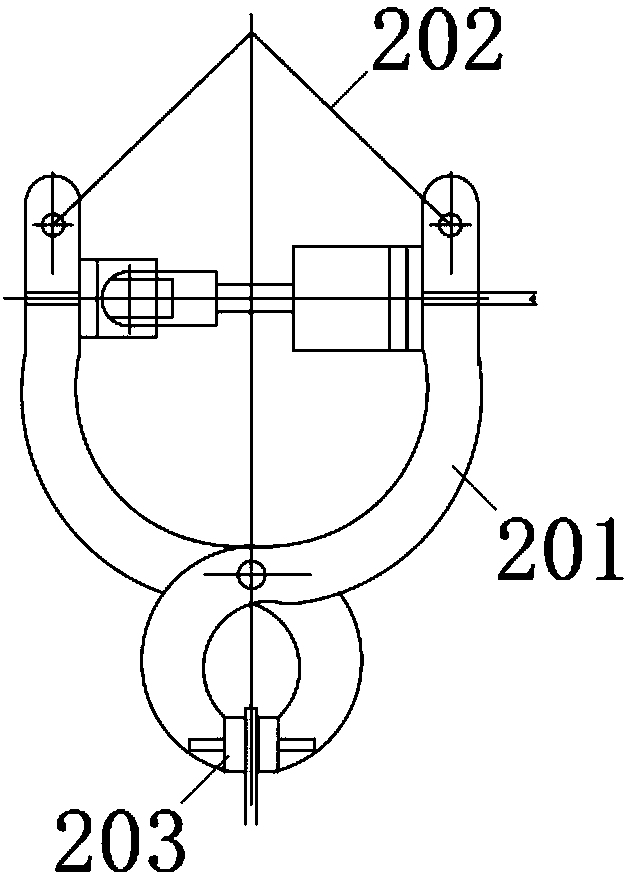

[0021] Such as figure 1 and 2 As shown, the copper processing horizontal continuous casting automatic feeding device includes a support, a balance crane 1 and a pneumatic clamp 2 for clamping or releasing an electrolytic copper block 3 .

[0022] The balance hanger 1 is rotatably arranged on the bracket. The bracket includes two parts, the upper bracket and the lower bracket. The lower part of the upper bracket and the upper part of the upper bracket are connected by a vertical shaft. The bottom of the upper bracket and the end of the rotating shaft are provided with gears, and the corresponding gears on the lower bracket are provided with drive motors, and the output shafts of the drive motors are provided with drive wheels meshed with the gears.

[0023] The balance crane 1 is hinged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com