Rail vehicles with bridge elements for bridging the gap between doors and platforms

A rail vehicle and component technology, applied in the field of rail vehicles, can solve the problems of height difference, inflexibility of step steps, inability to always completely bridge the edge of vehicles and platforms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

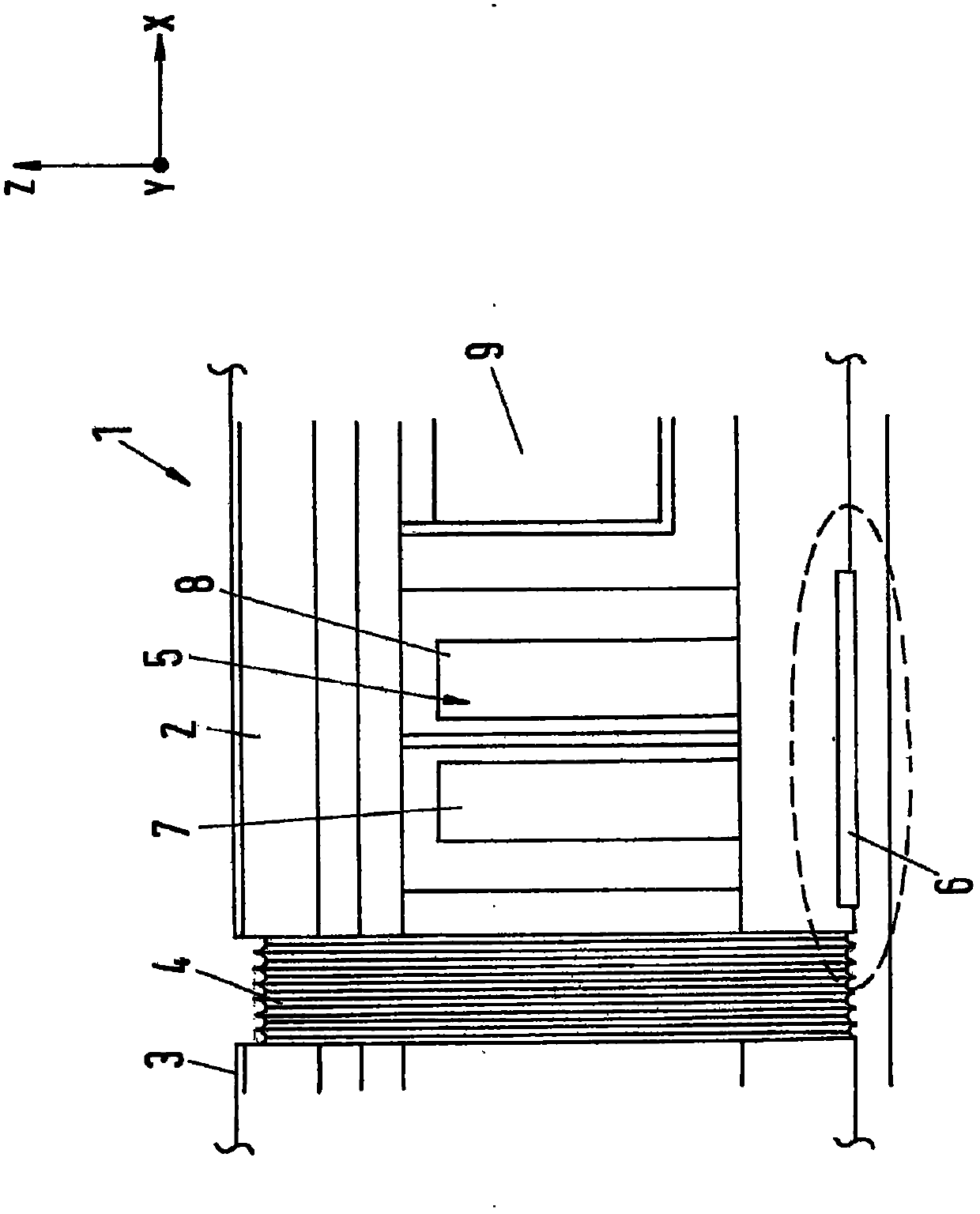

[0013] figure 1 A rail vehicle 1 is shown in partial detail, here a railroad track consisting of modules 2, 3

[0014] tram. The modules are connected by bellows 4 in the region of the not shown swivel-pitch hinges. exist

[0015] Below the door 5, a bridge element 6 is mounted on the rail vehicle 1 from the outside

[0016] Door. The bridge element 6 extends over the entire width of the door or the opening behind the door. observer's view

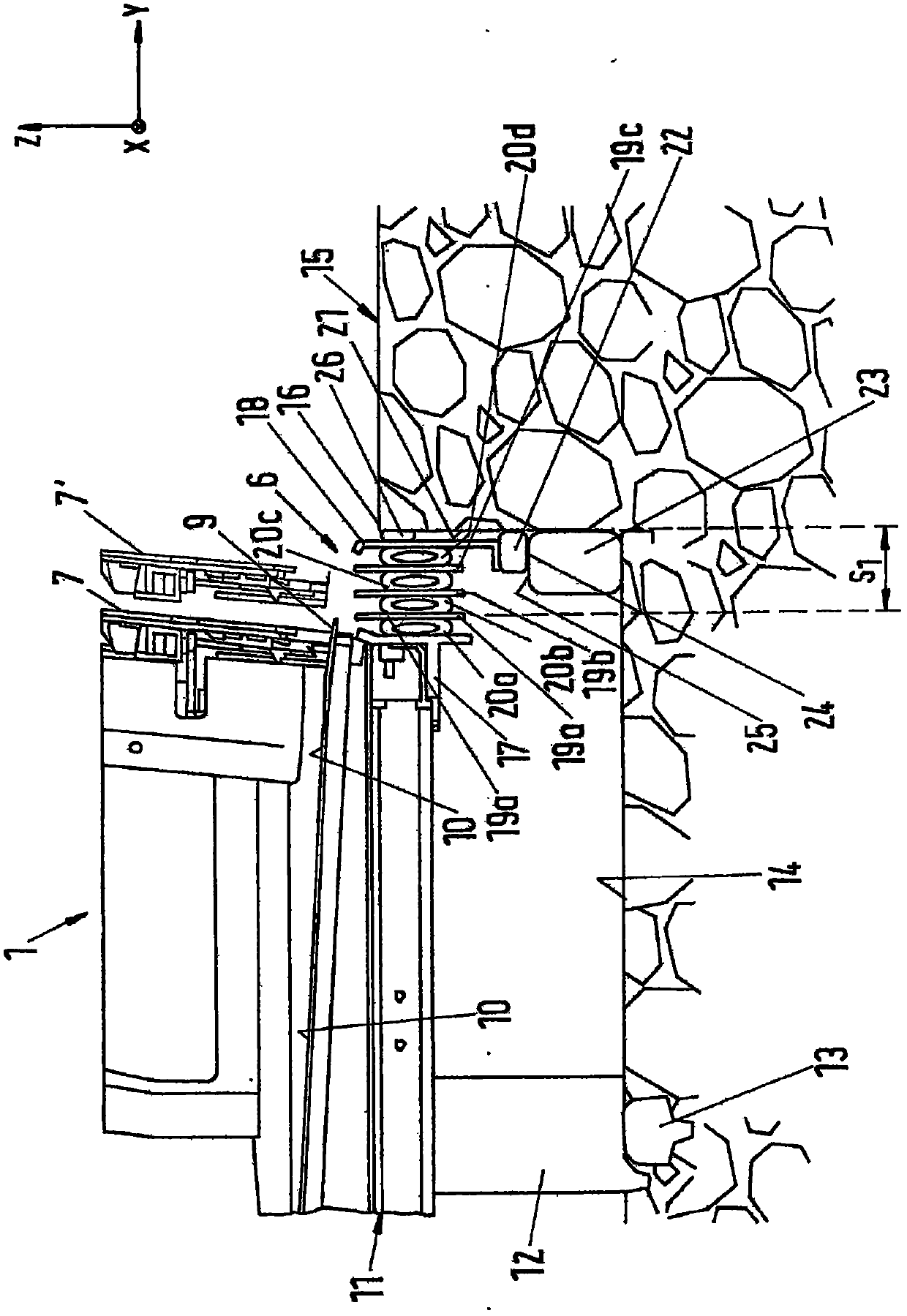

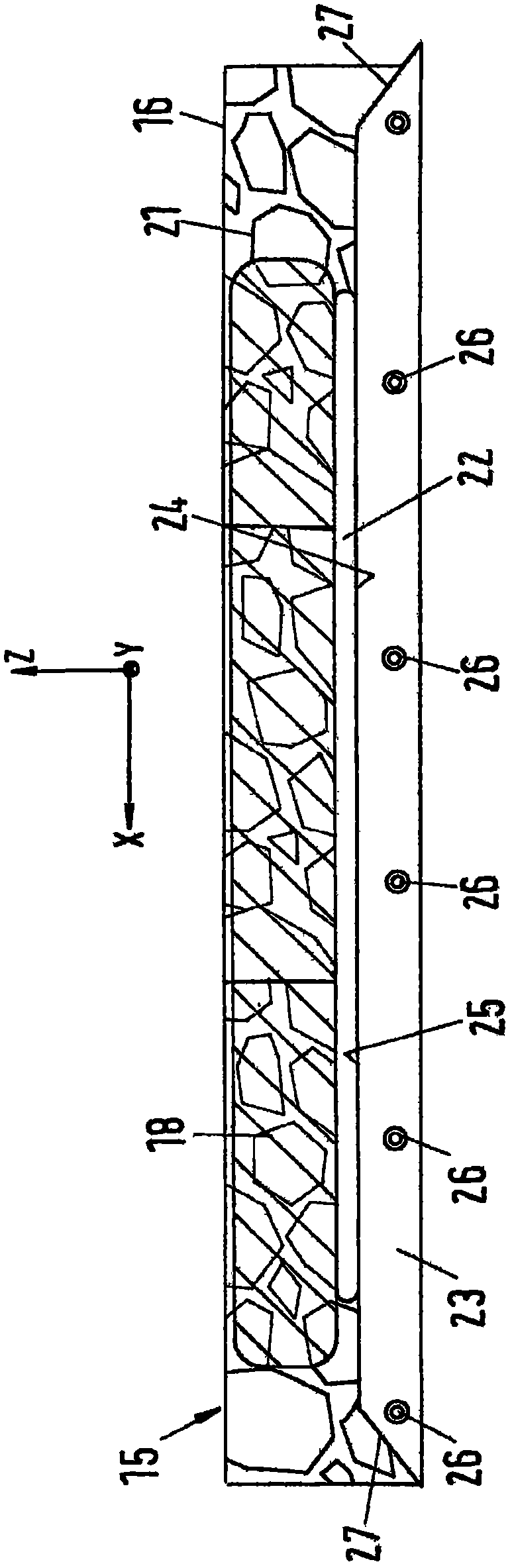

[0017] online figure 1 The center falls onto the end side of the bridge element 6 . exist figure 2 shows a rail vehicle in the area of the gate

[0018] 1 cross section. A closed door leaf 7 is shown in cross section, for example in figure 1 Middle left door leaf. Open

[0019] The door leaf and the door leaf moved to one side are indicated with the reference numeral 7'. to open, figure 1 The door leaf 7 in the

[0020] Move towards the observer and towards the bellows 4 side. figure 1 The door leaves 8 in the correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com