Novel bearing cap finished product box conveying rack

A technology for covering finished products and transporting frames is applied in the field of new bearing cover finished frame transport frames, which can solve the problems of laborious moving of workers, heavy weight of finished frames, low work efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

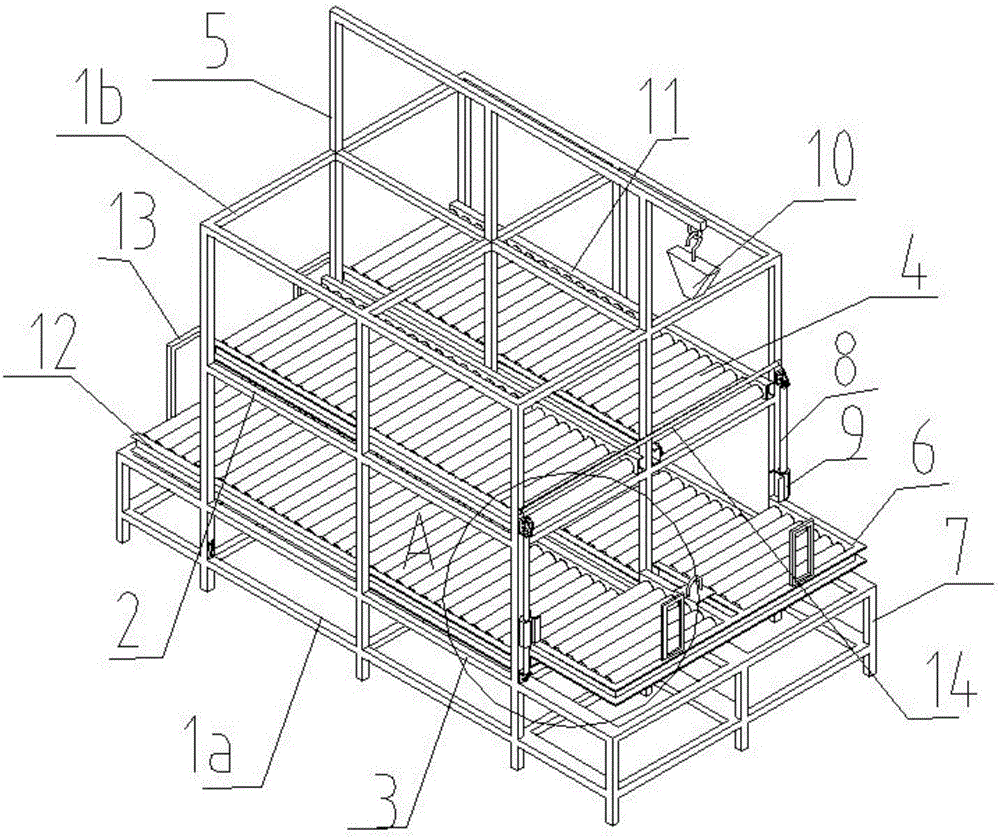

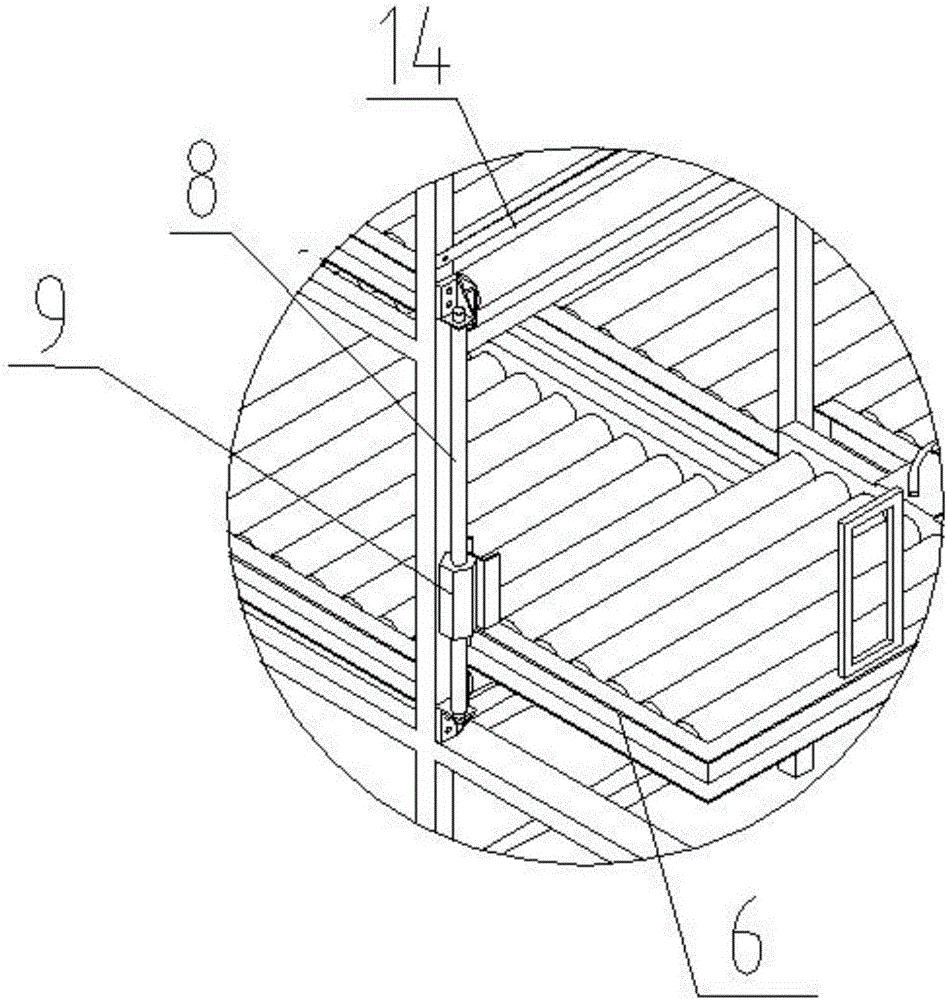

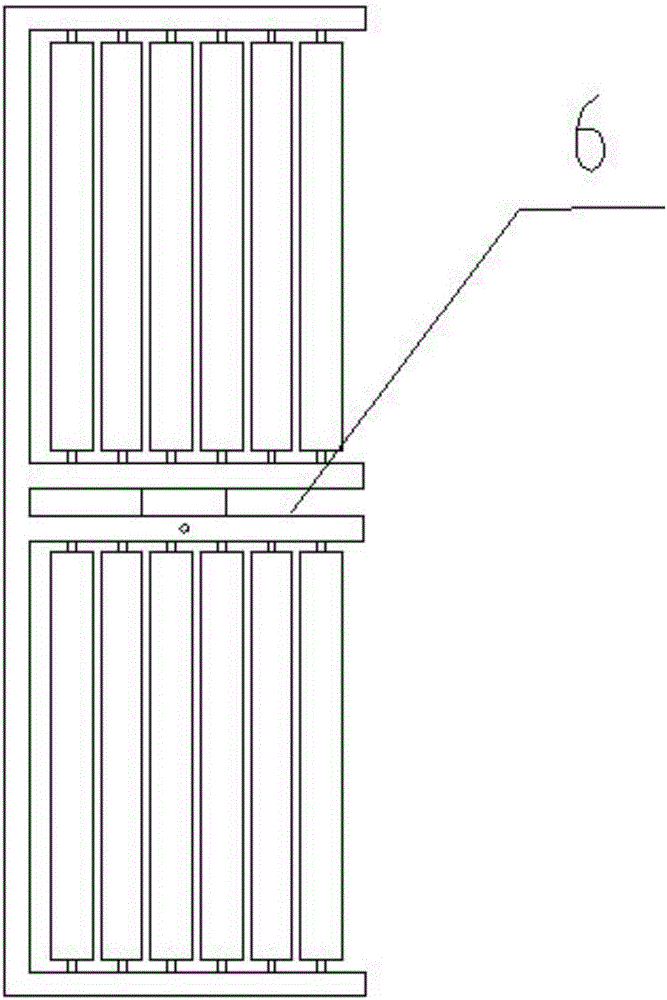

[0019] Such as Figure 1-5 Shown: the novel bearing cover finished product frame transportation frame of the present invention is made up of vertical frame, upper frame 2, lower frame 3, roller 4, electric hoist hanger 5, lifting frame 6, lifting frame supporting frame 7, lifting frame guide rail 8, Sleeve 9, electric hoist 10, upper roller table 11, lower roller table 12, railing 13 and empty frame bar 14 are formed.

[0020] The stand includes an upper rectangular frame 1a and a lower rectangular frame 1b, between the upper rectangular frame 1a and the lower rectangular frame 1b is an upper frame 2 and a lower frame 3, and the four corners of the upper rectangular frame 1a and the lower rectangular frame 1b are connected by columns respectively A column is also connected between the left and right sides and the middle of the front side of the upper rectangular frame 1a and the lower rectangular frame 1b, and the lower ends of all the columns extend downward to become support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com