Efficient wood shaving drying device

A drying device and shaving technology, which is applied in the direction of drying gas arrangement, drying solid materials, wood particle drying, etc., can solve the problems affecting the quality of particle boards, the drying effect process, etc., to achieve quality assurance, ensure drying effect, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

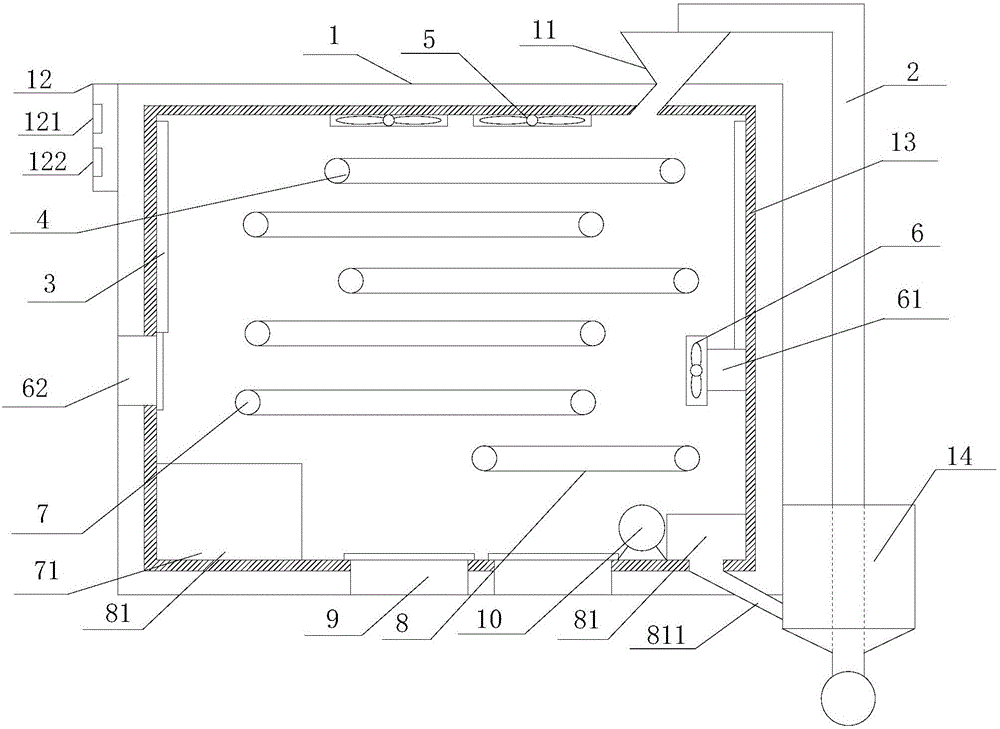

[0019] Refer to figure 1 The present invention is an efficient shavings drying device, including a drying chamber 1, a conveyor 2, an infrared electric heating plate 3, a drying conveyor belt 4, a first blower 5, a second blower 6, a conveying conveyor belt 7, a recycling conveyor belt 8, a first The air outlet 9 and the motor 10 are provided with a feeding hopper 11 at the upper left of the drying chamber 1, and a plurality of drying conveyor belts 4 are arranged below the feeding hopper 11. The drying conveyor belt 4 moves horizontally under the drive of the motor 10, so The second blower 6 is fixed on the right side wall of the drying chamber 1 by a mounting bracket 61, the second blower 6 is located on the right side of the discharge end of the drying conveyor belt 4, and a second outlet is also provided on the side wall of the drying chamber 1 The air outlet 62, the second air outlet 62 is flush with the second blower 6, a conveying belt 7 is provided under the drying conv...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap