An automatic shoe sole rubber brushing device

A sole glue and automatic brushing technology, which is applied in the direction of footwear, shoe parts bonding, shoemaking machinery, etc., can solve the problems of high hazards, etc., and achieve the effect of improving work efficiency and simple operation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

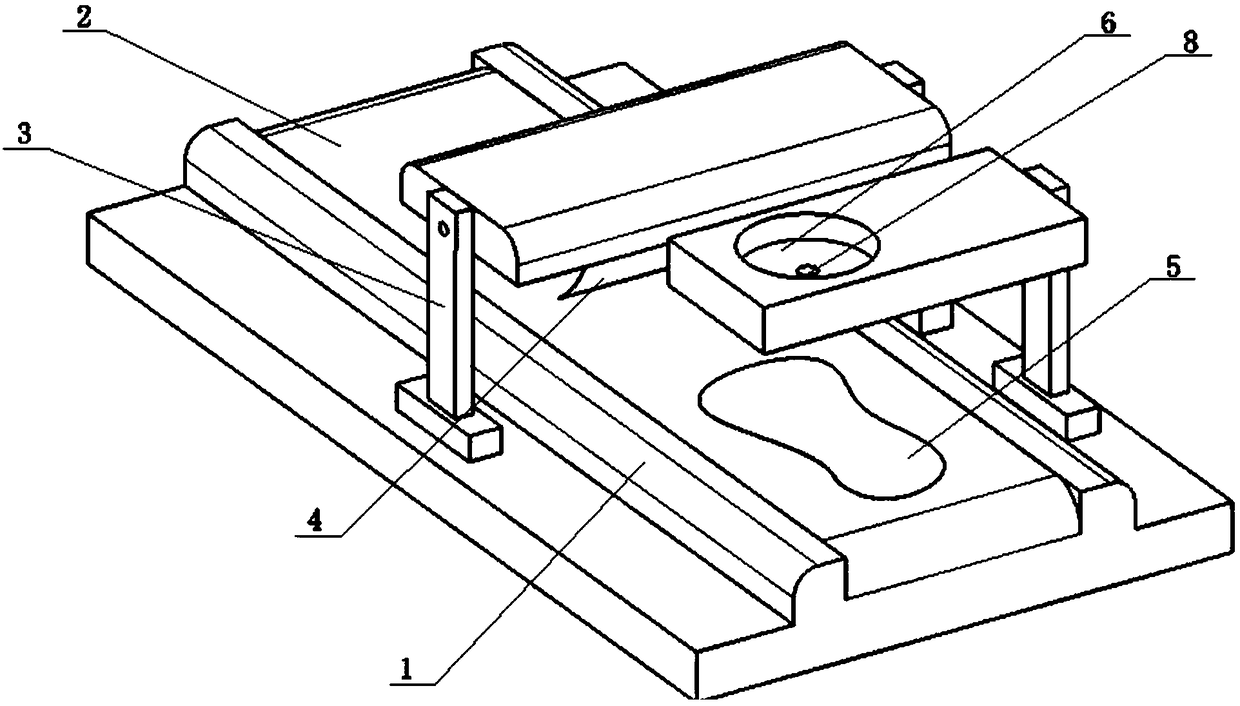

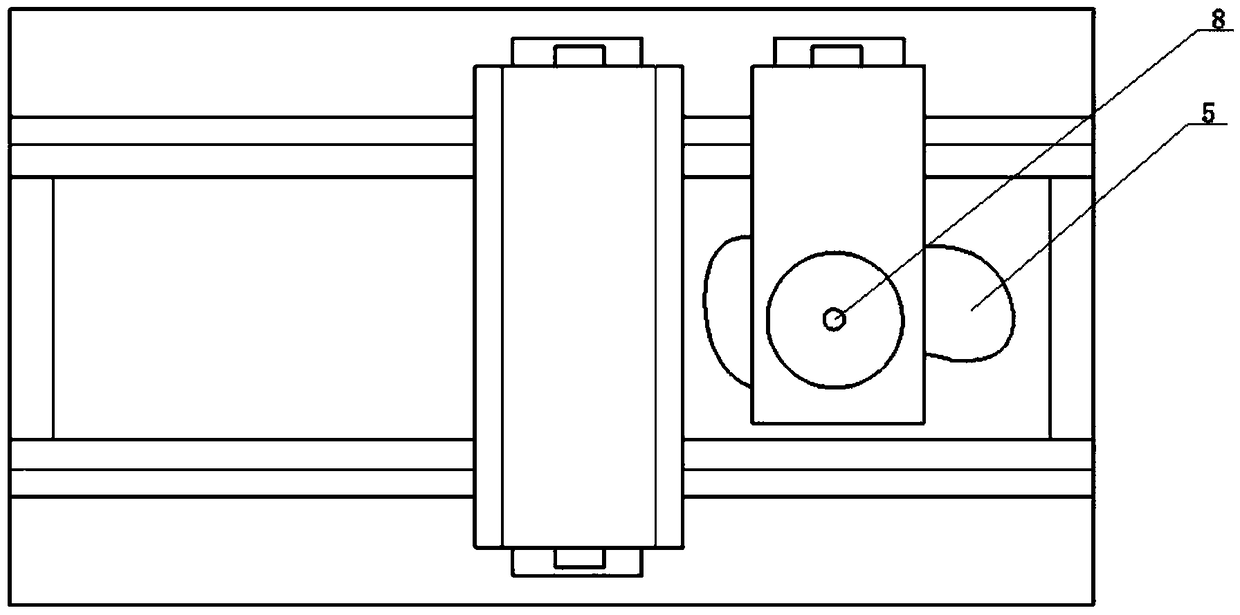

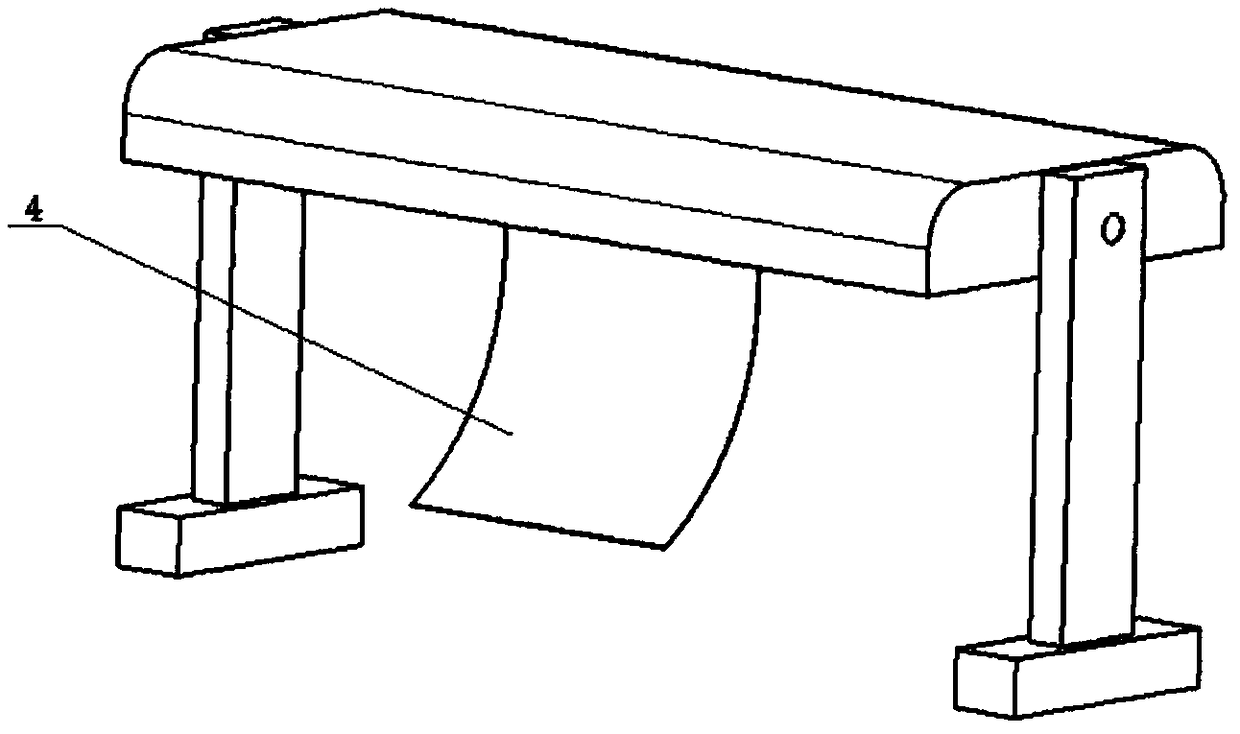

[0028] Such as figure 1 -Shown in 2, a kind of automatic shoe sole glue brushing device comprises workbench 1, glue releasing mechanism, glue brushing mechanism 3 and MCU,

[0029] The workbench 1 is provided with a transmission channel along its length direction. Two gears are arranged at both ends of the transmission channel. The inner side of a closed conveyor belt 2 meshes with the two gears and is tensioned. The rotation of the gear drives the conveyor belt 2 to run in the transmission channel.

[0030] The conveyor belt 2 is provided with a shoe model area 5 for placing the sole, and the gear rotates under t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com