Auxiliary support device for processing large thin-walled components and using method

A technology of auxiliary support and thin-walled components, which is applied in metal processing and other directions, can solve the problems of rigidity reduction, processing deformation, and lower hole-making efficiency, so as to avoid the influence of human factors, stabilize the quality of hole-making processing, and improve the manufacturing efficiency. Effect of hole machining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

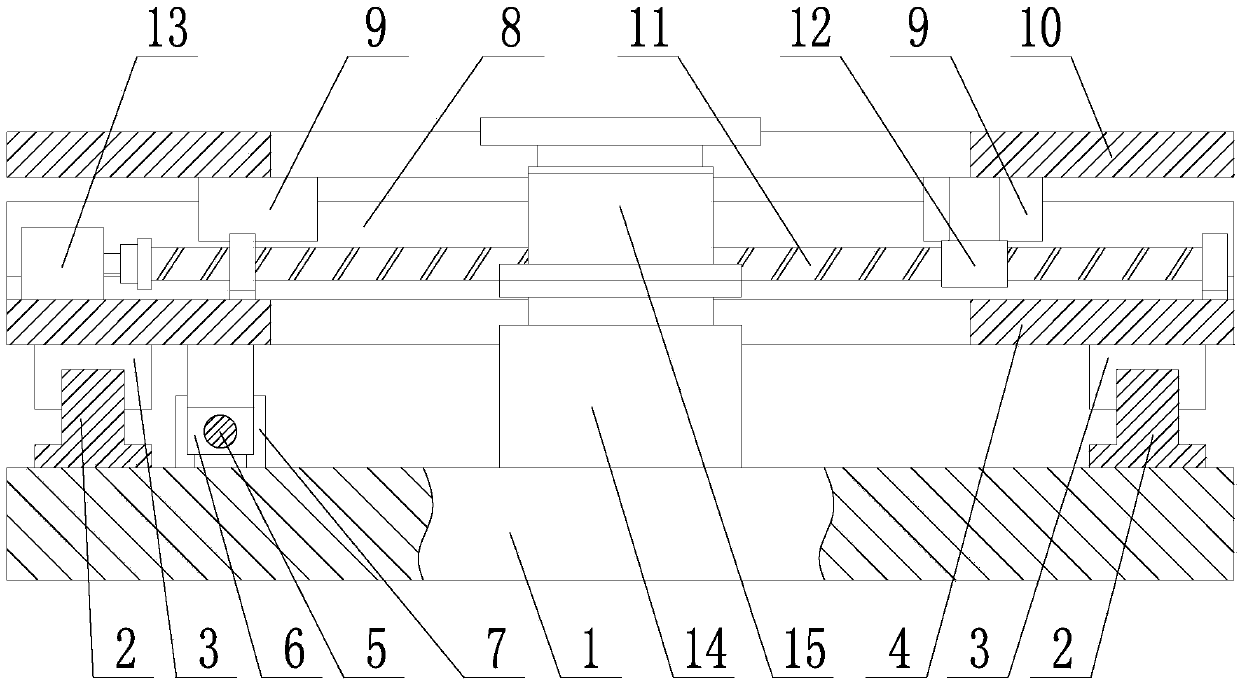

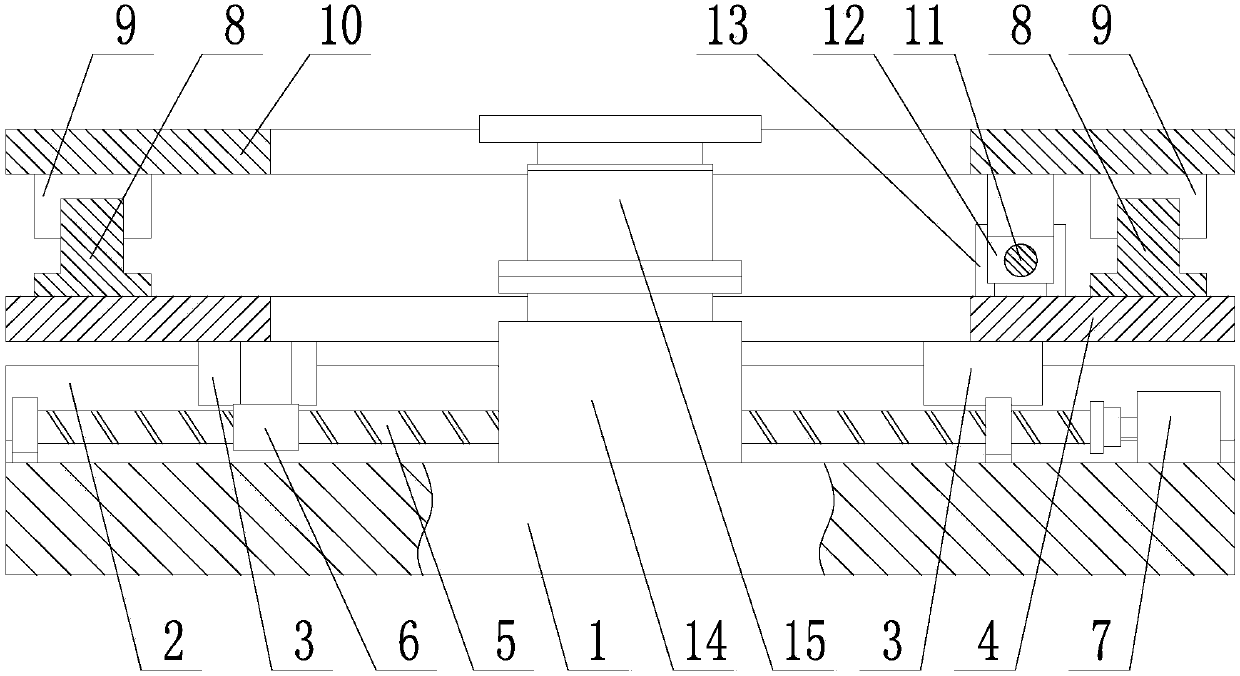

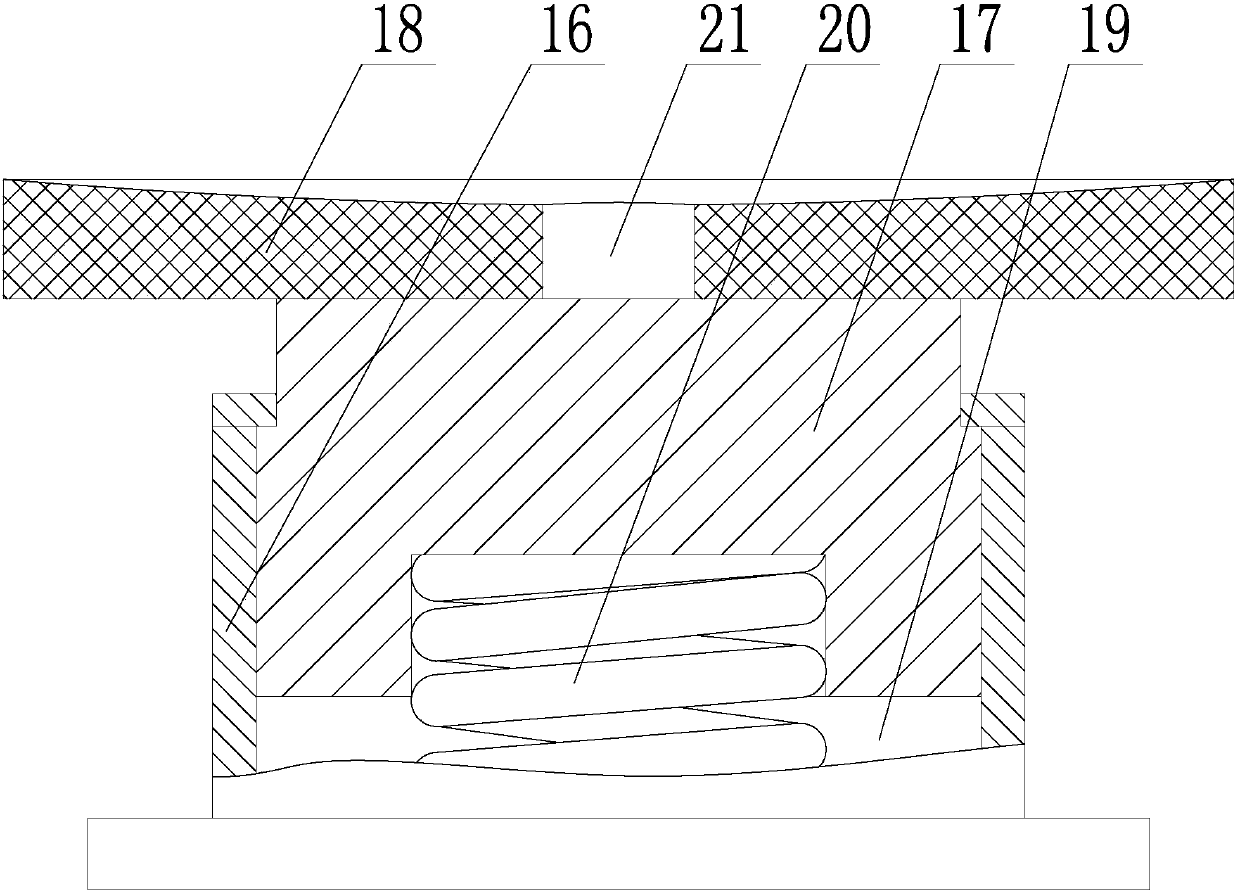

[0038] Such as Figure 1~3 As shown, an auxiliary support device for processing large thin-walled components, including a base 1, an X-direction position adjustment unit, a Y-direction position adjustment unit, and a Z-direction position adjustment unit;

[0039] The X-direction position adjustment unit includes an X-direction rail 2, an X-direction slider 3, an X-direction platform 4, an X-direction screw rod 5, an X-direction nut 6 and an X-direction drive motor 7; the X-direction rail 2 is horizontally fixed Installed on the upper surface of the base 1, there are two X-guiding rails 2 distributed in parallel; the X-direction slider 3 is arranged on the X-guiding rail 2, and the X-direction slider 3 and the X-guiding rail 2 are horizontally slidable; The platform 4 is fixedly installed on the X-direction slider 3, the X-direction s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com