Film take-up structure for digital film printing

A technology of digital printing and membrane structure, applied in the direction of printing device, printing, etc., to achieve the effect of automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

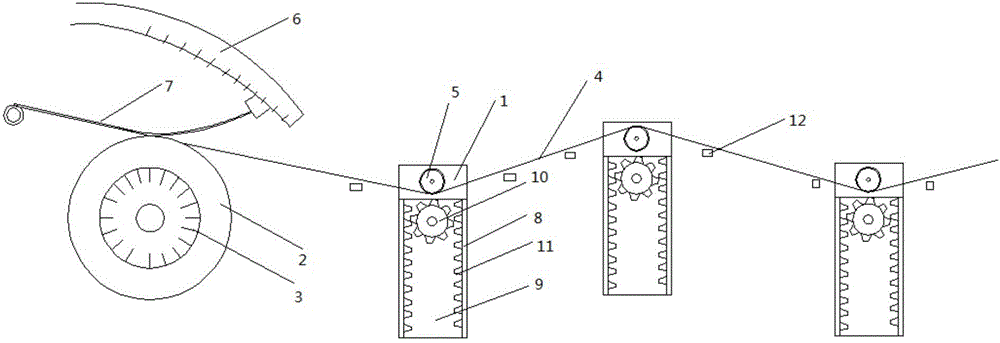

[0010] Refer to the attached drawings, a film-receiving structure for film digital printing, including a number of side-by-side high-low staggered pre-tightening adjusting seats 1, film-retracting wheel 2, and the film-receiving wheel 2 is coaxially provided with a code plate 3, film-receiving wheel 2 Driven by a motor, the film 4 passes through the pre-tightening wheels 5 of several pre-tightening adjusting seats 1 in turn, and the film collecting wheel 2 is wound to collect the film 4. A code bar 6 and an arc-shaped code pin are arranged above the film collecting wheel 2 7. The outer wall of the arc-shaped code needle 7 is pressed on the film of the film-retracting wheel 2. The pre-tightening adjusting seat 1 includes a square adjusting seat 8. The upper end of the adjusting seat 8 is equipped with a pre-tightening wheel 5, and the lower part of the adjusting seat 8 is provided with a groove. The slot 9 is provided with a driving gear 10 driven by a motor, and two sides of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com