Full-automatic shoulder piece sewing equipment

A fully automatic, sewing technology that is used in sewing machines, sewing machine components, textiles and papermaking to solve problems such as inconsistent output, low sewing efficiency, and quality differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

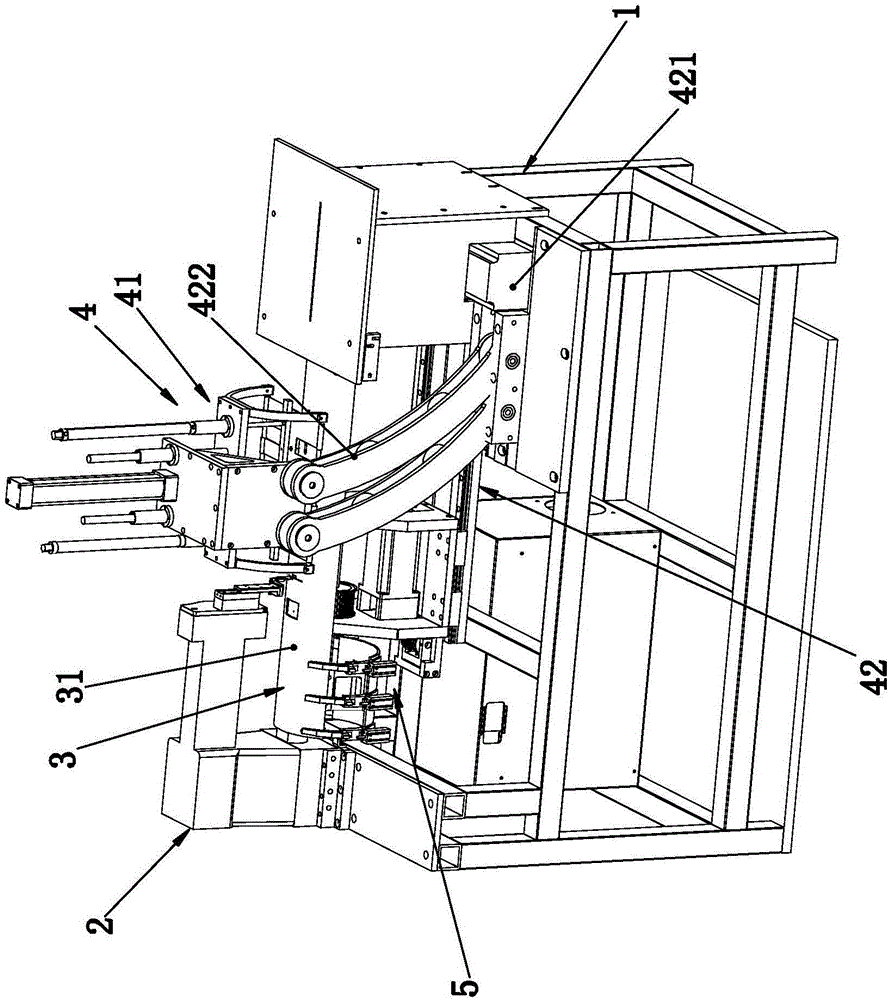

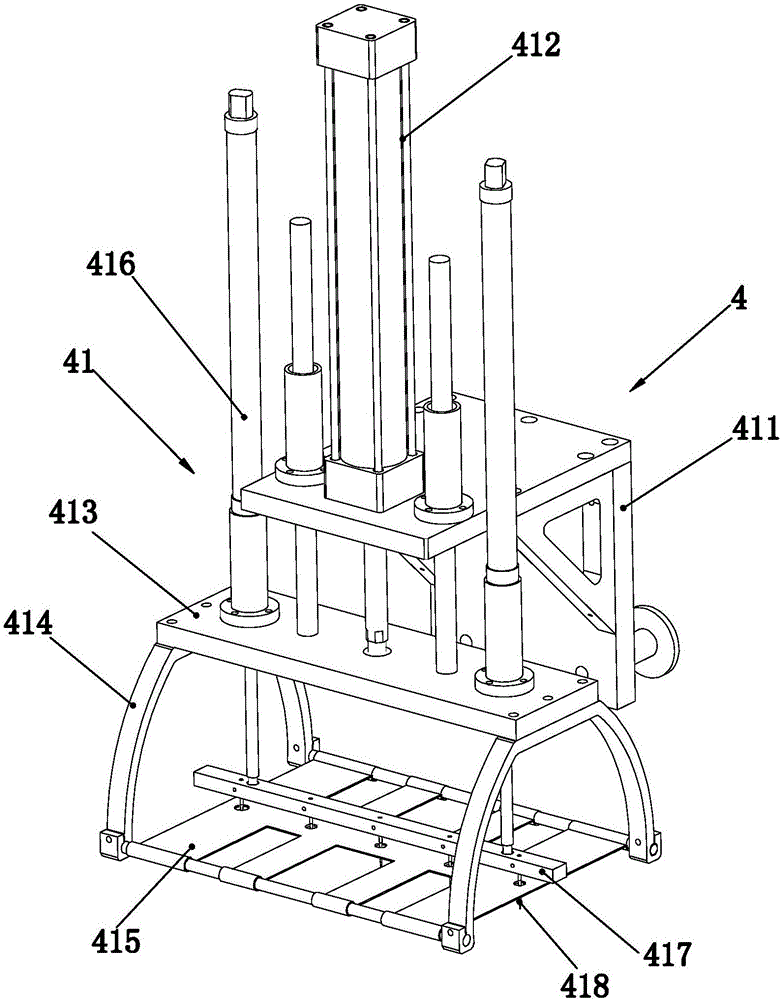

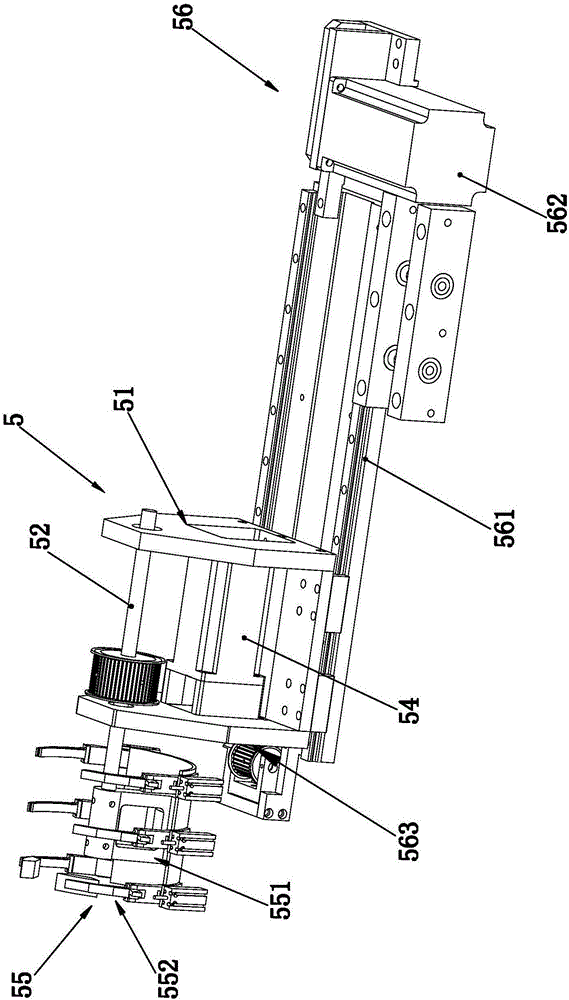

[0023] Such as figure 1 — Figure 5 A full-automatic shoulder padding sewing equipment shown includes a body 1, a sewing machine 2 erected on the body 1, a sewing platform 3 corresponding to the sewing machine 2, and a sewing object can be positioned on the sewing platform 3 and can be positioned along the sewing platform. 3 A positioning device 4 for longitudinal reciprocating movement and an angle adjusting device 5 for making the sewing object to be on the sewing platform 3 at a swing angle. In the process of the above scheme, several pieces of cloth for processing the shoulders are stacked on the sewing platform 3, and then positioned by the positioning device 4 to prevent it from falling off the sewing platform 3, and then the sewing machine 2 is used to align them. Implement sewing, and adjust the sewing angle of the object to be sewn by the angle adjusting device 5 during the sewing process, so that the edge of the object to be sewn is sewn. This process does not requ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com