Slide Switch Tool

A sliding sleeve switch and tool technology, which is applied in the direction of mining fluid, wellbore/well parts, earthwork drilling and production, etc., can solve the problems of affecting service life and high running resistance, so as to prolong service life, avoid obstruction and realize safety The effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below with reference to the accompanying drawings.

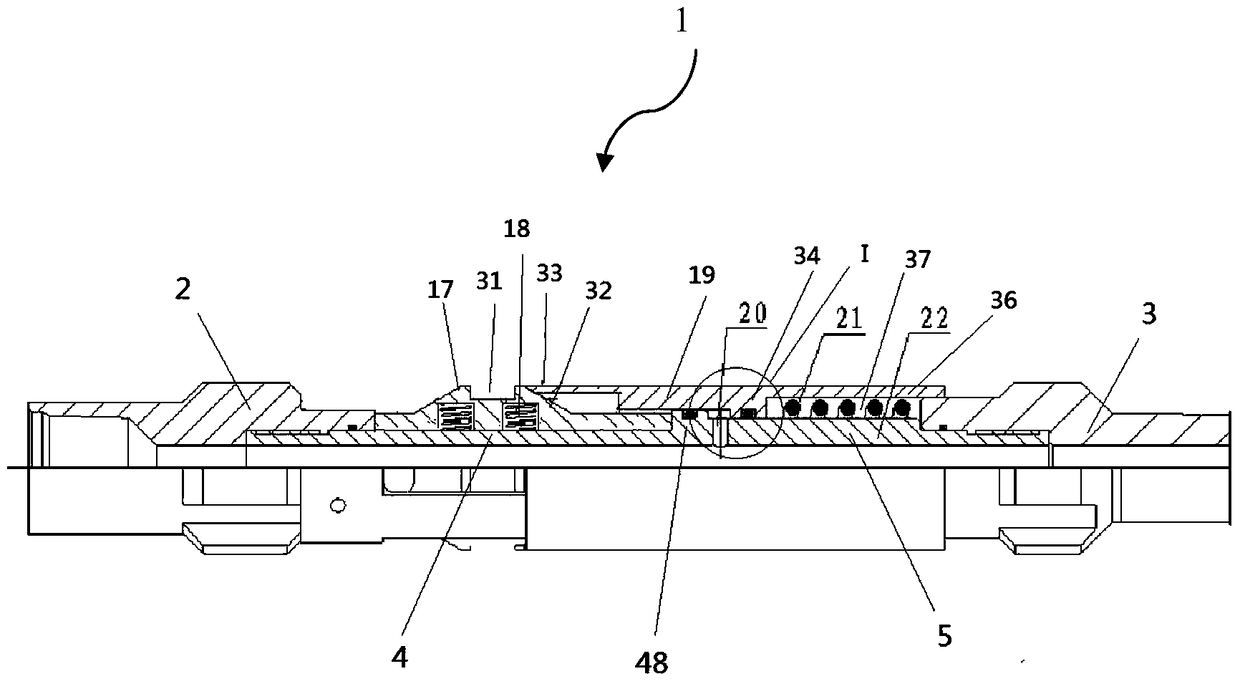

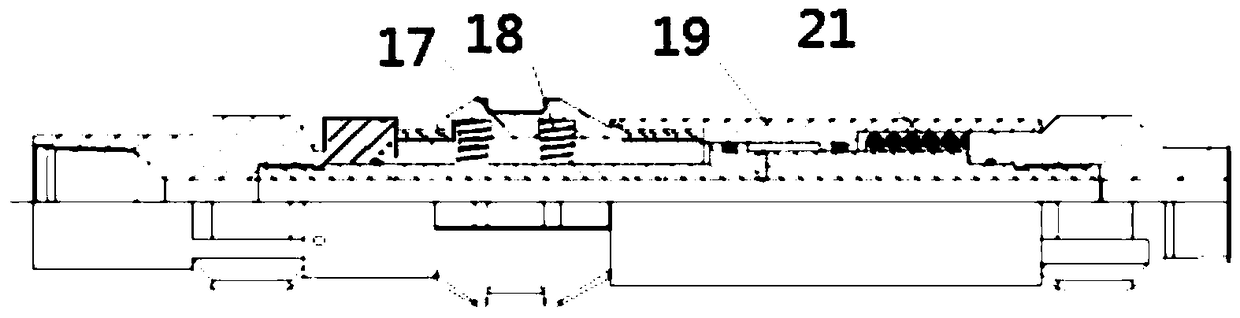

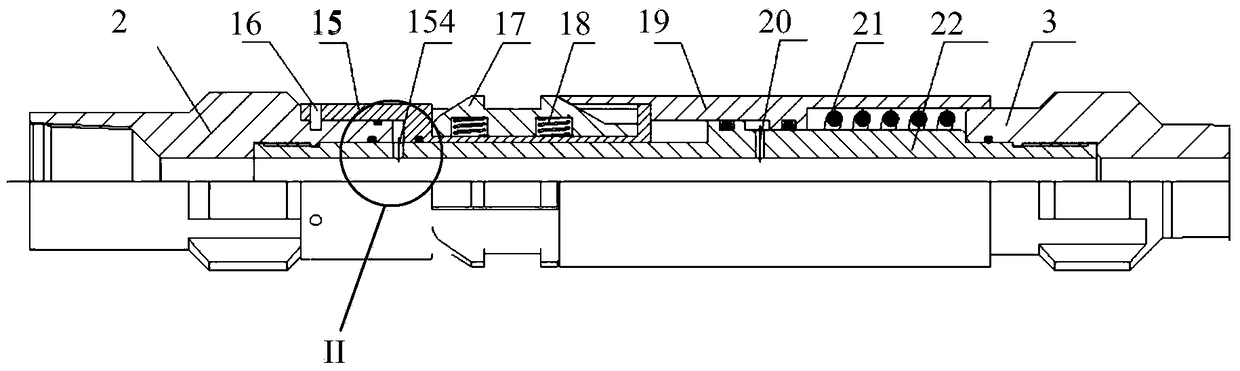

[0026] figure 1 The structure of the slide switch tool 1 according to the first embodiment of the present invention is schematically shown. like figure 1 As shown, the sliding sleeve switch tool 1 includes a cylindrical body 22 having a radially outwardly projecting shoulder 48 disposed on the outer surface of the cylindrical body 22 . Thereby, the cylindrical body 22 is divided into the upstream portion 4 and the downstream portion 5 . The end of the upstream portion 4 of the cylindrical body 22 is connected to the upper joint 2 , and the end of the downstream portion 5 is connected to the lower joint 3 . The cylindrical body 22 , the upper joint 2 and the lower joint 3 are all hollow structures, so that the interior of the cylindrical body 22 can be filled with hydraulic fluid.

[0027] Sliding switch tool 1 also includes a sliding sleeve 60 (see Figure 7 ) engag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com