A cascaded peak-shaving system and its operating method for improving thermal power flexibility of thermal power units

A thermoelectric unit, flexible technology, applied in the direction of mechanical equipment, steam engine devices, engine components, etc., can solve problems such as lack of flexibility of the unit, and achieve high practical application value, reliable performance, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0021] Example.

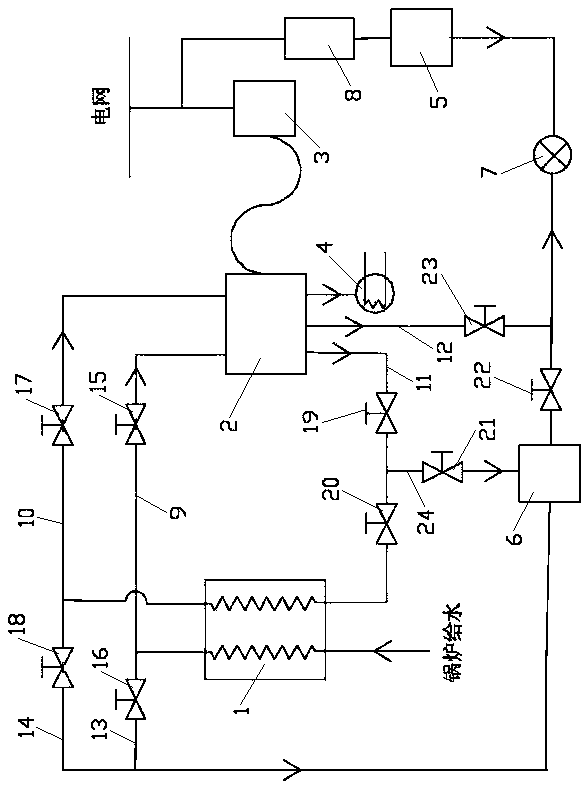

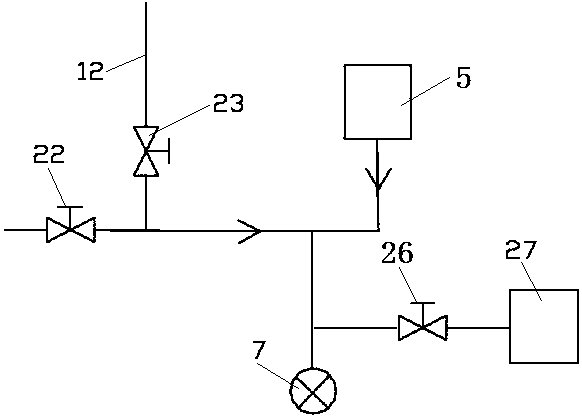

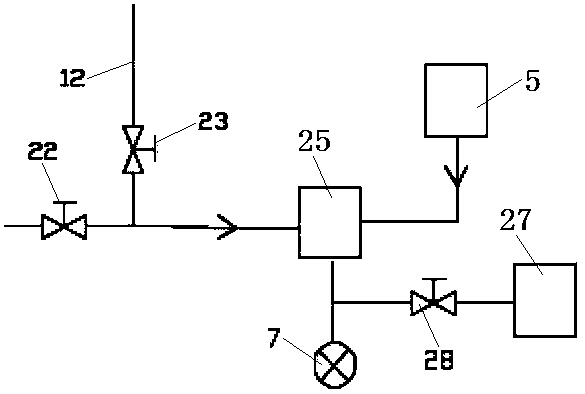

[0022] see Figure 1 to Figure 3 , the cascaded peak-shaving system for improving thermal power flexibility of thermal power units in this embodiment includes a boiler 1, a steam turbine 2, a generator 3, a condenser 4, an electric furnace 5, a temperature and pressure reduction device 6, a thermal user 7, and a current and voltage Adjusting device 8, main steam pipe 9, hot reheat steam pipe 10, cold reheat steam pipe 11, heat supply and extraction pipe 12, main steam branch 13, hot reheat steam branch 14, valve A15, valve B16, Valve C17, valve D18, valve E19, valve F20, valve G21, valve H22, valve K23 and cold reheat steam branch 24.

[0023] Boiler 1 in this embodiment is connected to steam tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com