Modular frameless down lamp

A frame tube and module technology, which is applied to the components of lighting devices, semiconductor devices of light-emitting elements, lighting and heating equipment, etc. problems, to achieve the effect of reducing procurement costs and construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

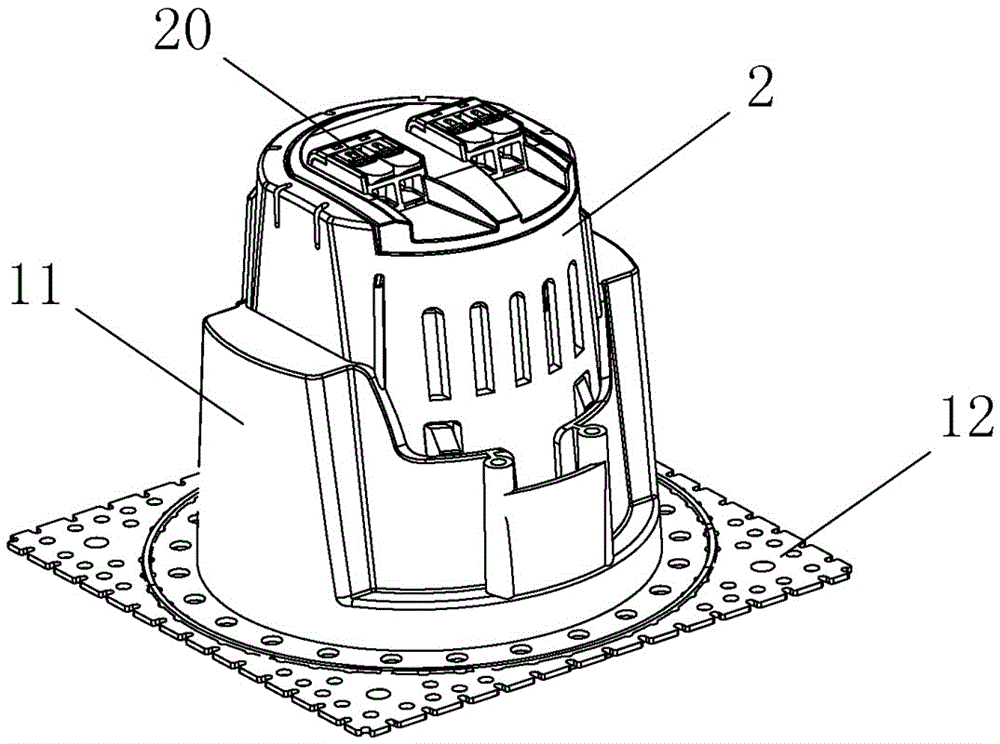

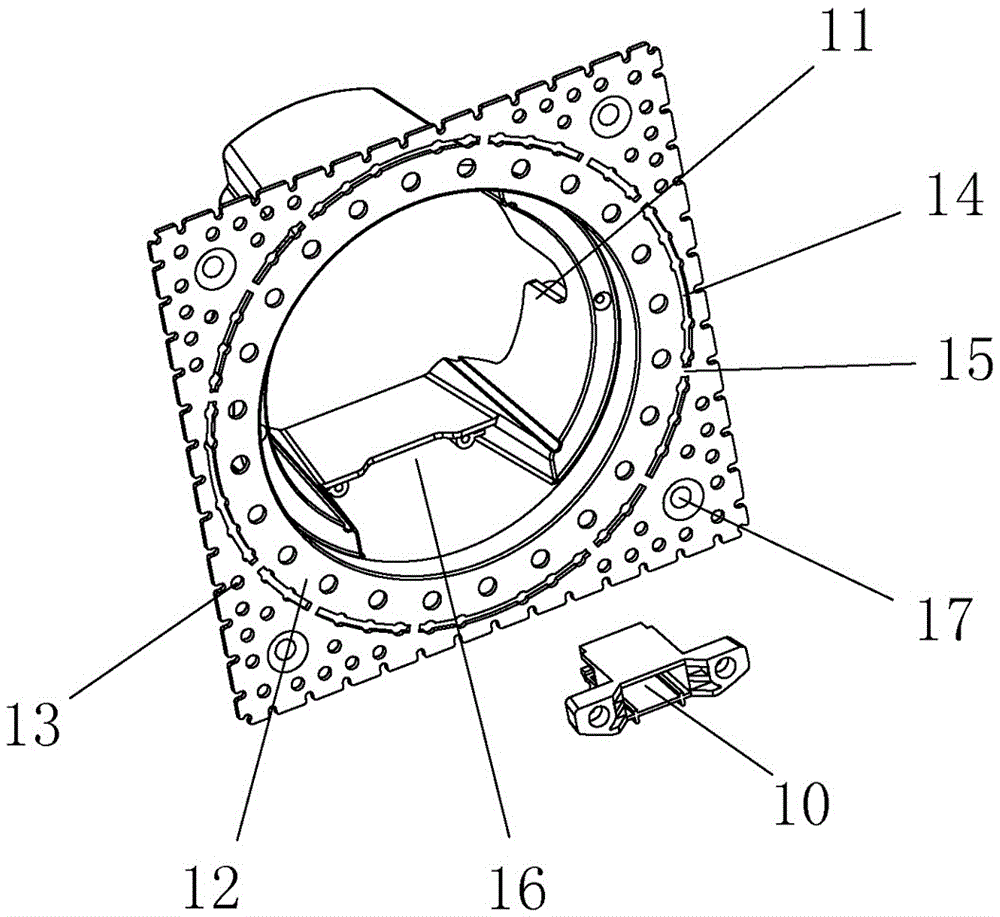

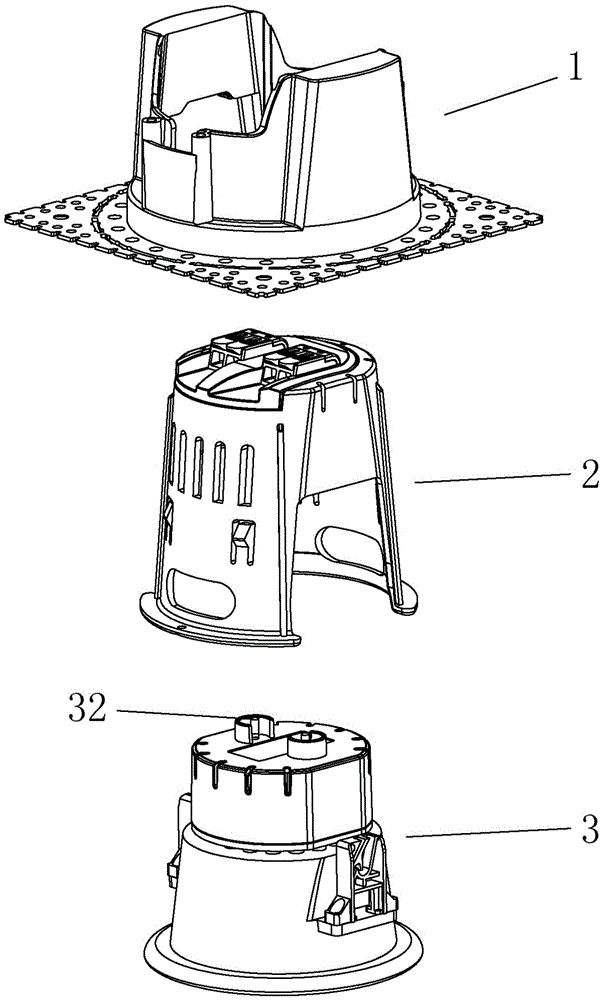

[0024] refer to Figure 1 to Figure 6 , a modular borderless downlight, consisting of three parts: an embedded part 1, an intermediate part 2 and a lamp body 3, the intermediate part 2 is connected to the embedded part 1, and the lamp body 3 is installed In the middle part 2, a fastening structure is provided between the lamp body 3 and the middle part 2 or the embedded part 1 .

[0025] The connecting structure includes a clamping seat 10 provided on the embedded part 1 and a clamping joint 30 provided on the lamp body 3. In this embodiment, the inner wall of the embedded part 1 is provided with A cavity 16 with an opening downward, the clamping seat 10 is fixed in the cavity 16 by screws, the outer wall of the lamp housing 33 of the lamp body 3 is provided with a connecting piece 38, and the clamping joint 30 is fixed by screws on the connecting piece 38 . The snap joint 30 and the snap socket 10 form a rebound self-locking structure, which is also called a rebound self-lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com