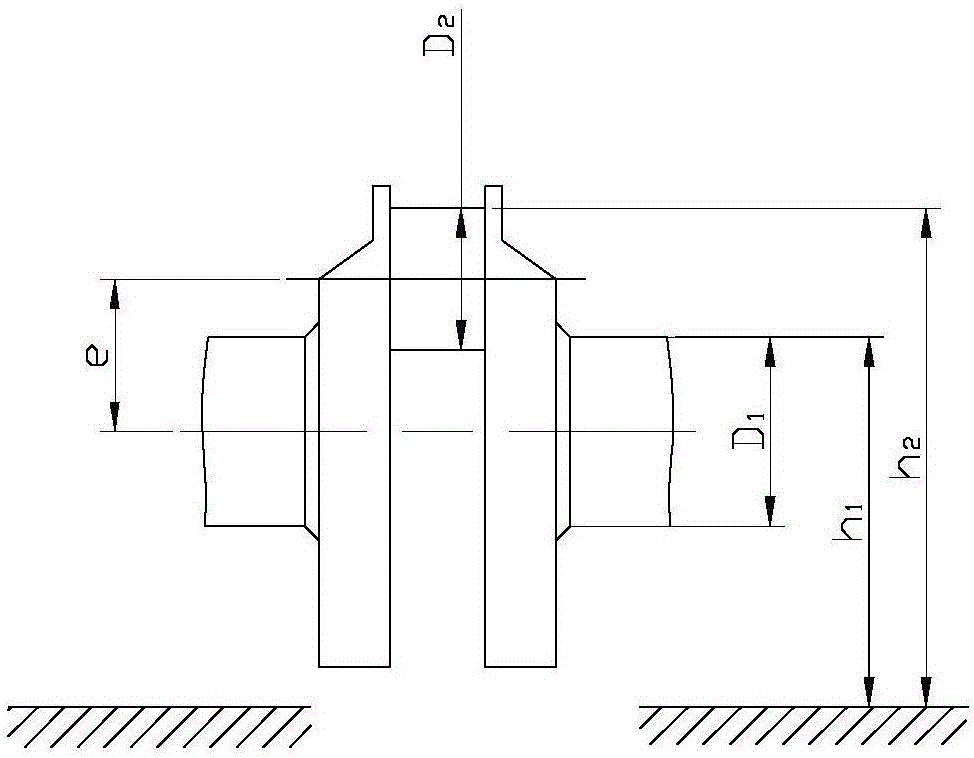

Universal measuring tool for eccentricity of crankshaft type part

A technology of eccentricity and crankshaft, applied in the field of measuring tools, can solve the problems such as the improvement of the measurement efficiency and the large amount of calculation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

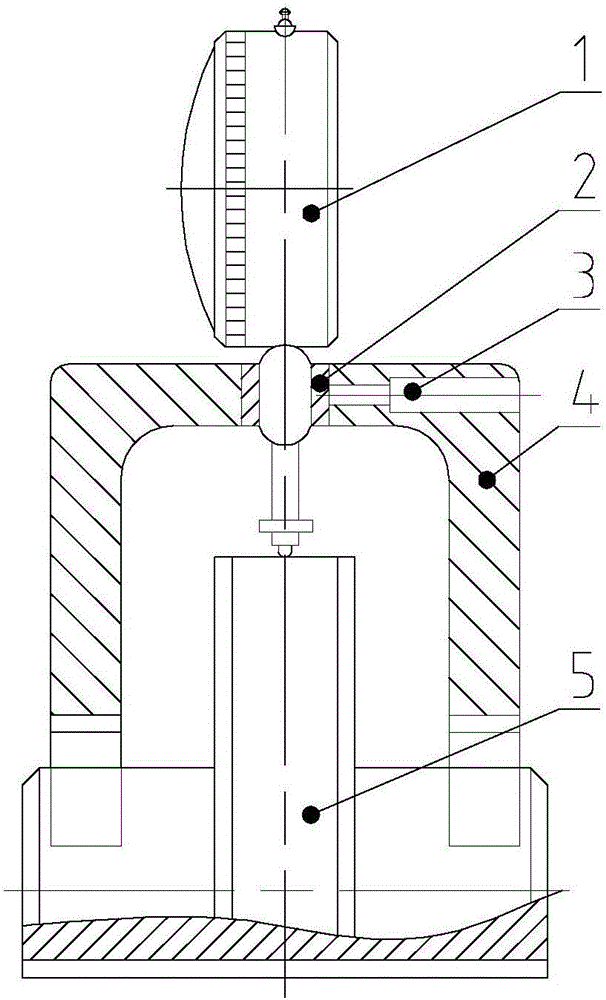

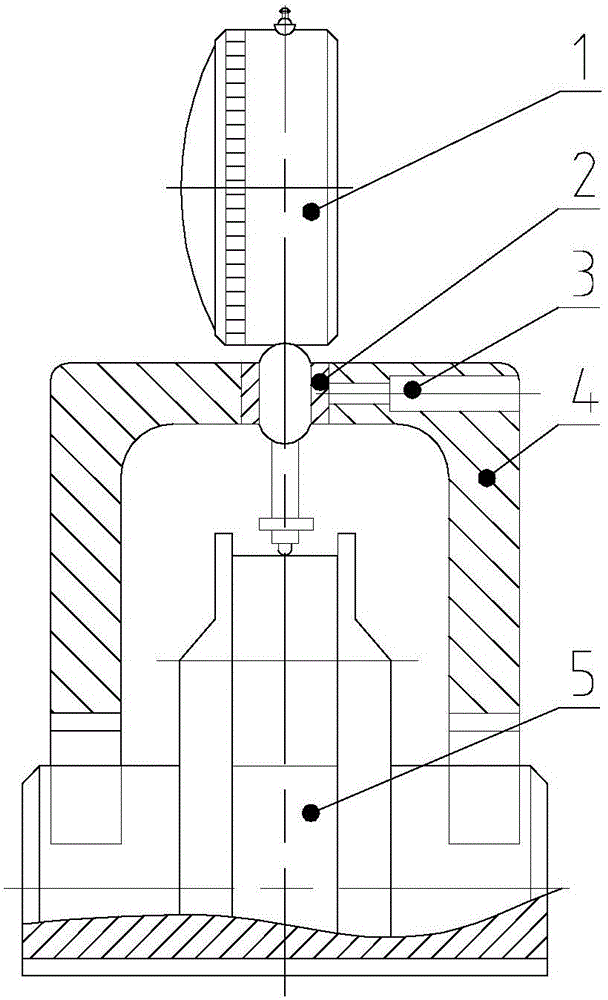

[0013] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

[0014] Such as figure 2 , image 3 As shown, a kind of crankshaft-like parts eccentricity universal measuring tool includes a dial gauge 1, an open bush 2 and a V-shaped table frame 4, and the V-shaped table frame 4 has two legs symmetrically arranged, and the two legs Located at the same horizontal position, the two legs are used to symmetrically place two sections of the main journal of the crankshaft workpiece. The upper part of the V-shaped table frame 4 has a through hole, and the opening bush 2 is arranged in the through hole. The sub-meter 1 passes through the opening bushing and is fixed on the opening bushing 2 by the screw 3, and the measuring rod and the measuring head of the dial indicator extend into the V-shaped meter frame 4.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com