A Mechanical Manual High Space Lighting Control Device

A control device and high-space technology, which is applied in the direction of lighting devices, lighting auxiliary devices, lighting device components, etc., can solve the problems of narrow space in corridors and stairwells, scattered lighting layout, heavy weight, etc., to improve erection efficiency, Effect of Mechanical Adjustment Process Stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

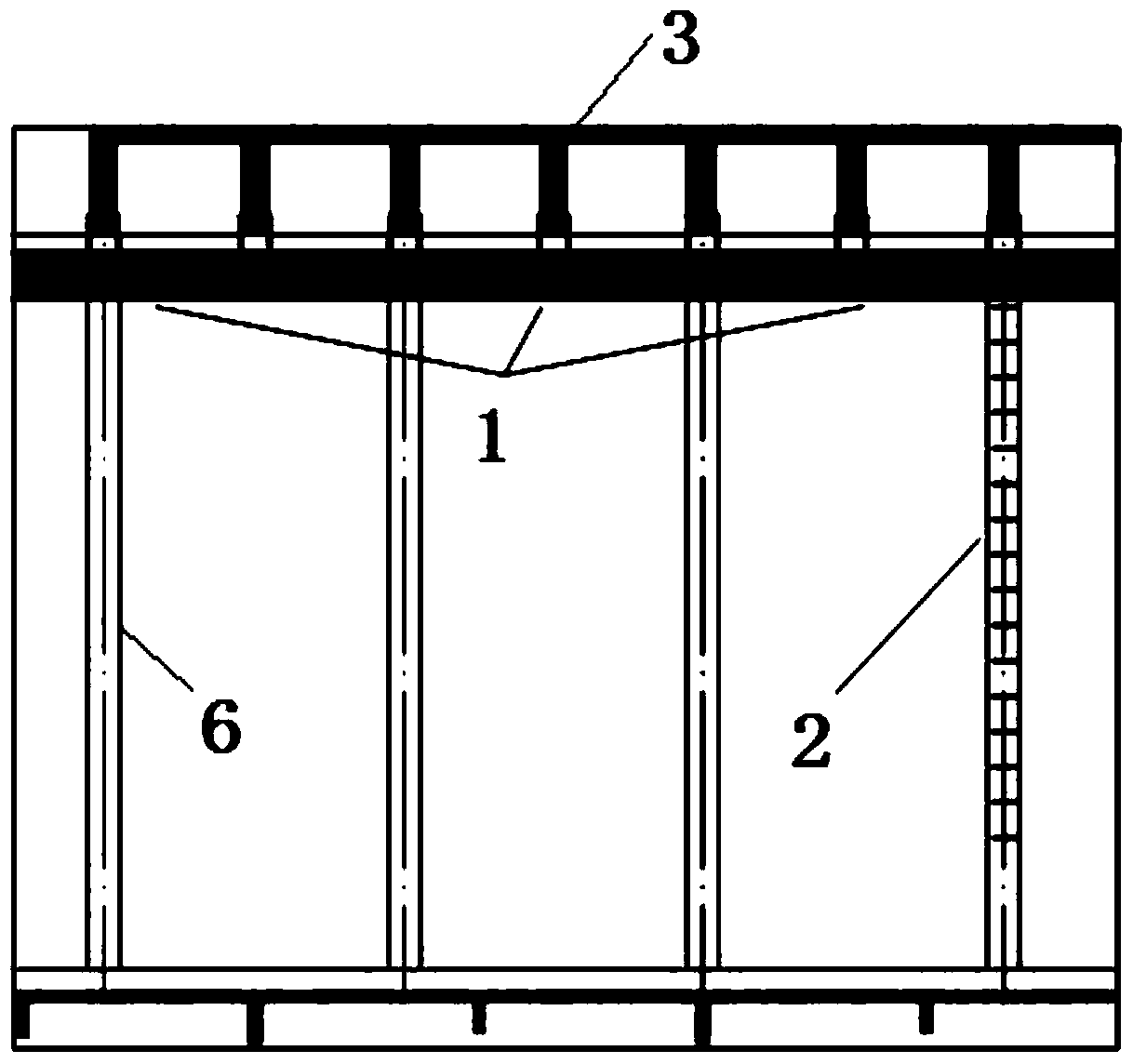

[0025] Such as figure 1 As shown, along the layout direction of each row of lamps, build a cantilever maintenance platform of about 0.8m against one side wall, and set up a ladder on the platform, which can be accessed from the ground.

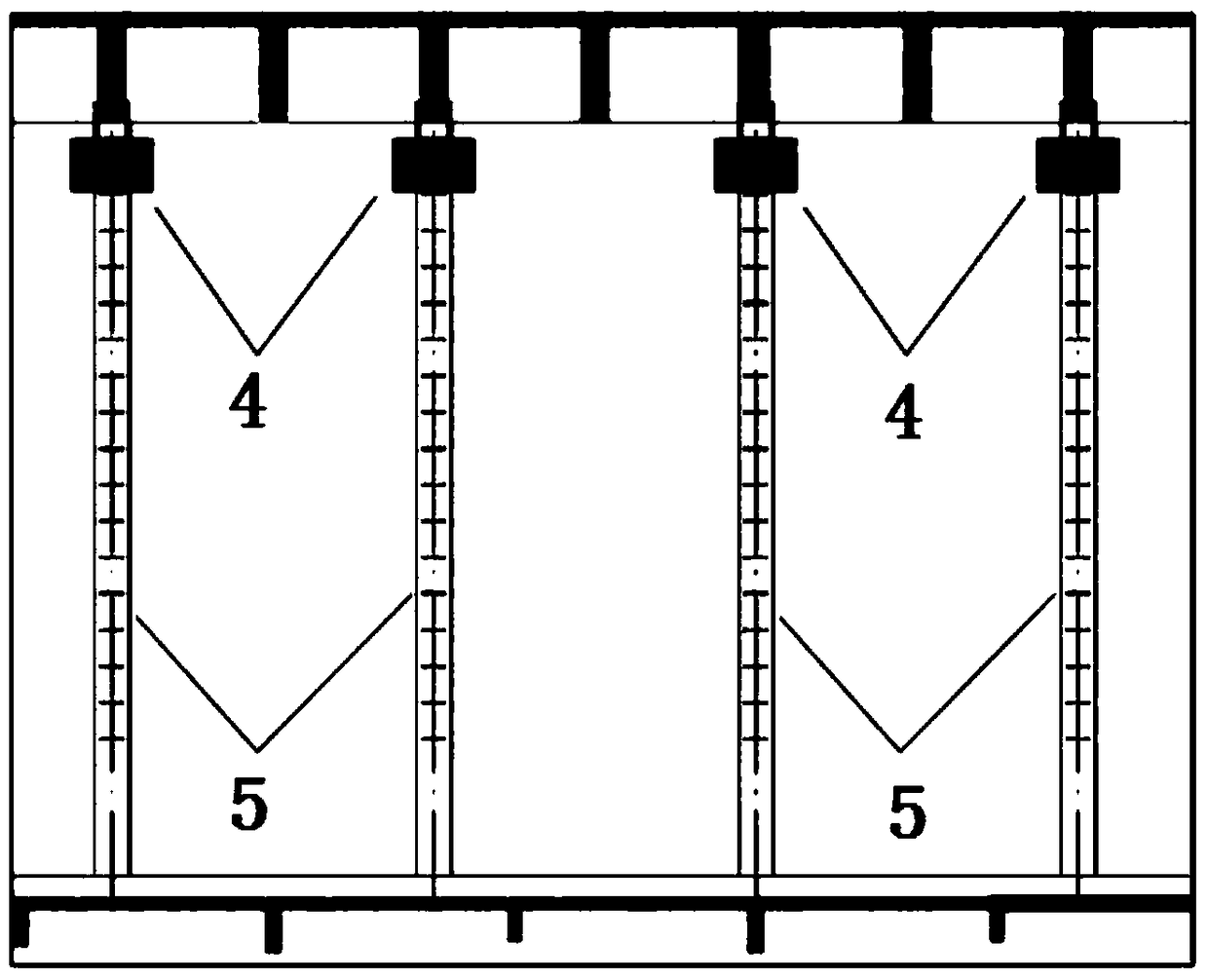

[0026] Such as figure 2 As shown, the maintenance platform can also be provided with a small maintenance platform on one side of each row of lamps, cantilevered on the wall and provided with a ladder.

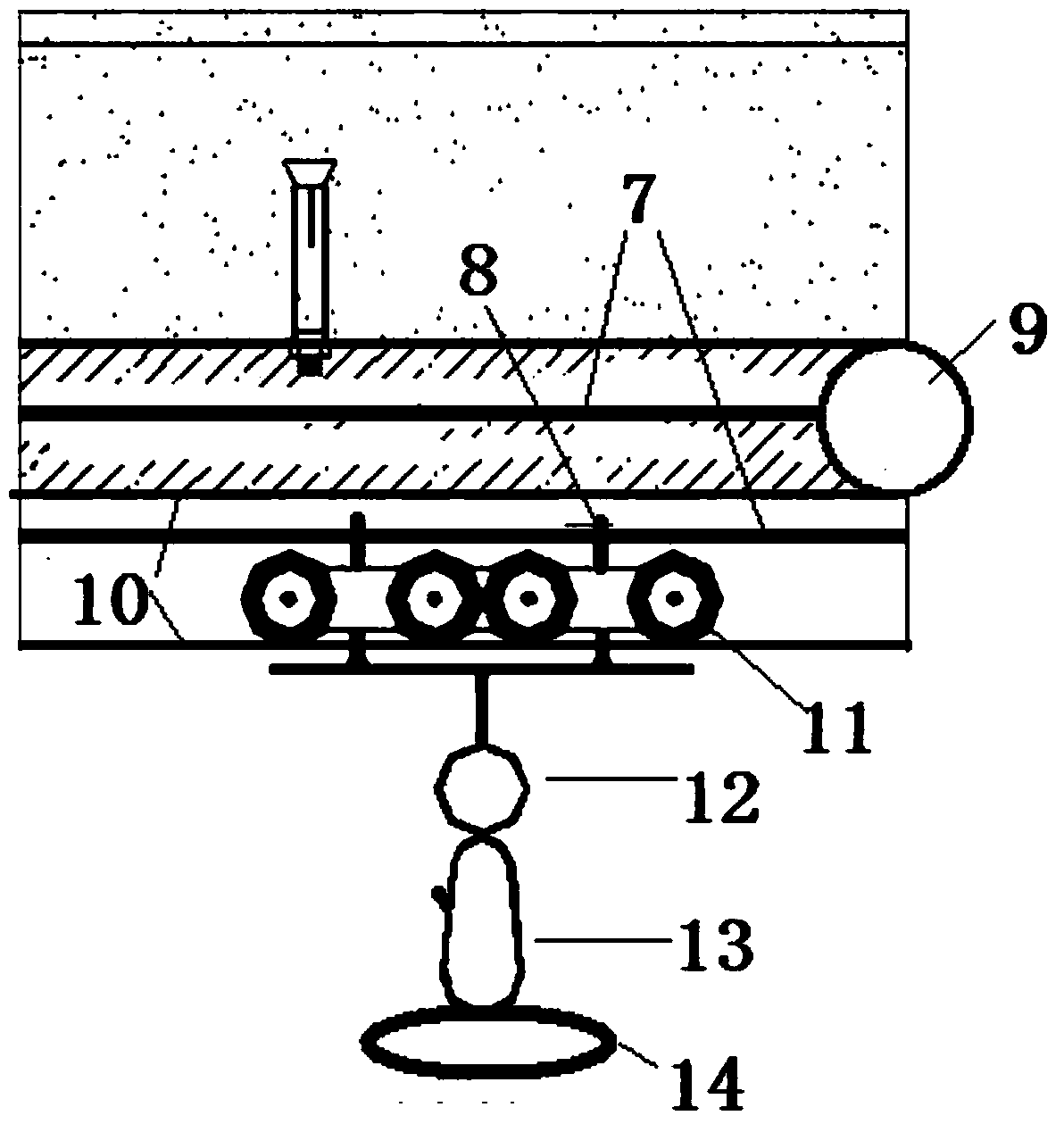

[0027] Such as image 3 Schematic diagram of the installation structure for lamps and track systems, such as Figure 4 Install the vertical structure diagram for the take-up system, such as Figure 5 Schematic diagram of the lateral structure for the installation of the take-up system.

[0028] A mechanical manual control device for high-space lamps, which includes a take-up and release system, a maintenance platform, a lamp and a track system.

[0029] The take-up and pay-off system is the adjustment control structure of the whole device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com