Sectorial sealplate and manufacturing method thereof

A fan-shaped sealing plate and manufacturing method technology, applied in the direction of manufacturing tools, engine sealing, indirect carbon dioxide emission reduction, etc., can solve the problems of high production cost of the fan-shaped sealing plate, shorten the production cycle, facilitate flatness correction, The effect of reducing the total number of welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

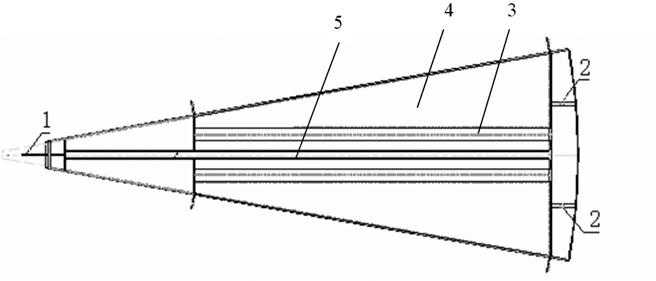

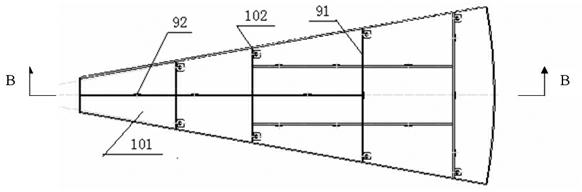

[0038] The following combination Figure 2 to Figure 7 , a preferred embodiment of the present invention is described in detail.

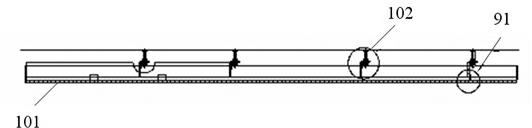

[0039] Such as figure 2 and image 3 Shown is a schematic structural view of an embodiment of the fan-shaped sealing plate provided by the present invention. It includes a fan-shaped steel plate 101, several supporting devices 102 and reinforcing ribs arranged on the fan-shaped steel plate 101.

[0040] Wherein, the fan-shaped steel plate 101 is integrally formed.

[0041] The plurality of supporting devices 102 are arranged on the top surface of the fan-shaped steel plate 101 at intervals along the two side chords of the fan-shaped steel plate 101 . Such as Figure 4 As shown, the supporting device 102 includes a supporting angle steel 8 connected to the fan-shaped steel plate 101 , and a nut 7 and a matching bolt 6 arranged on the supporting angle steel 8 .

[0042] Such as figure 2 and Figure 5 As shown, the reinforcing ribs include s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com