Correction method for capacitive material level sensing device and anti-interference method for multiple capacitive material level sensing devices

A technology of a sensing device and a calibration method, applied in the calibration of capacitive material level sensing devices, and the anti-interference field of complex capacitive material level sensing devices, can solve problems such as mutual interference, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] For the detailed description and technical content of the present invention, please refer to the following detailed description and description of the accompanying drawings, and the accompanying drawings and detailed description are only for illustrative purposes and are not intended to limit the present invention.

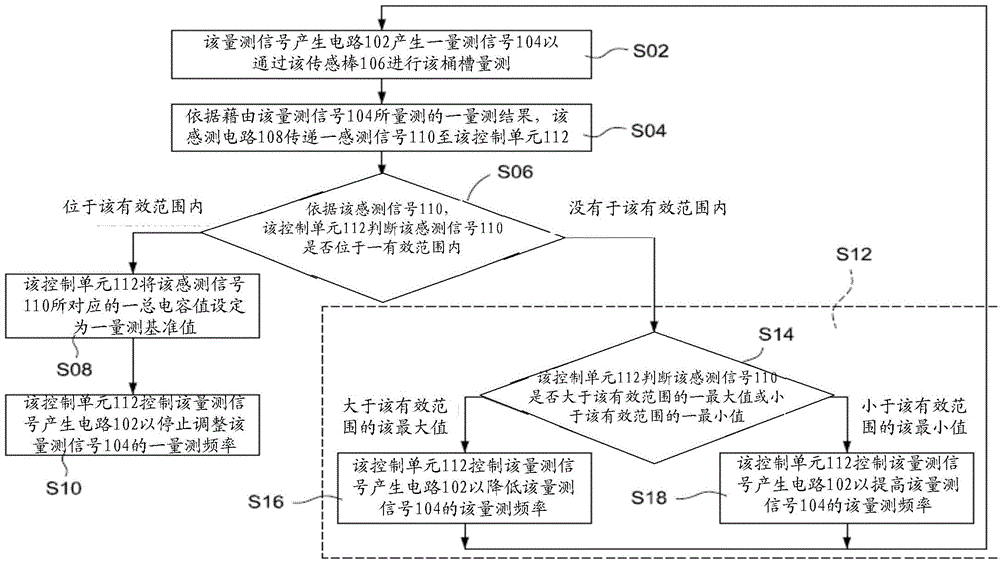

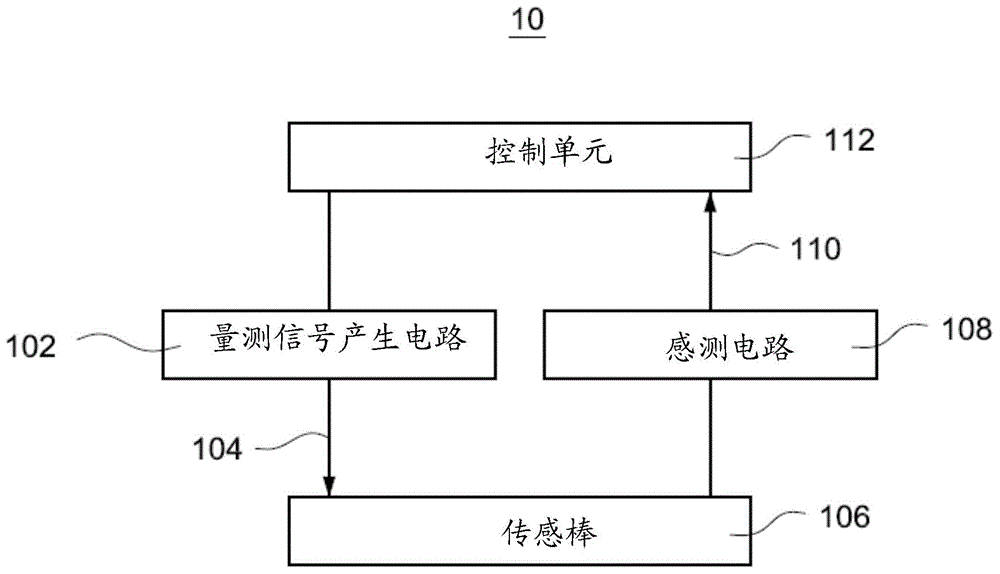

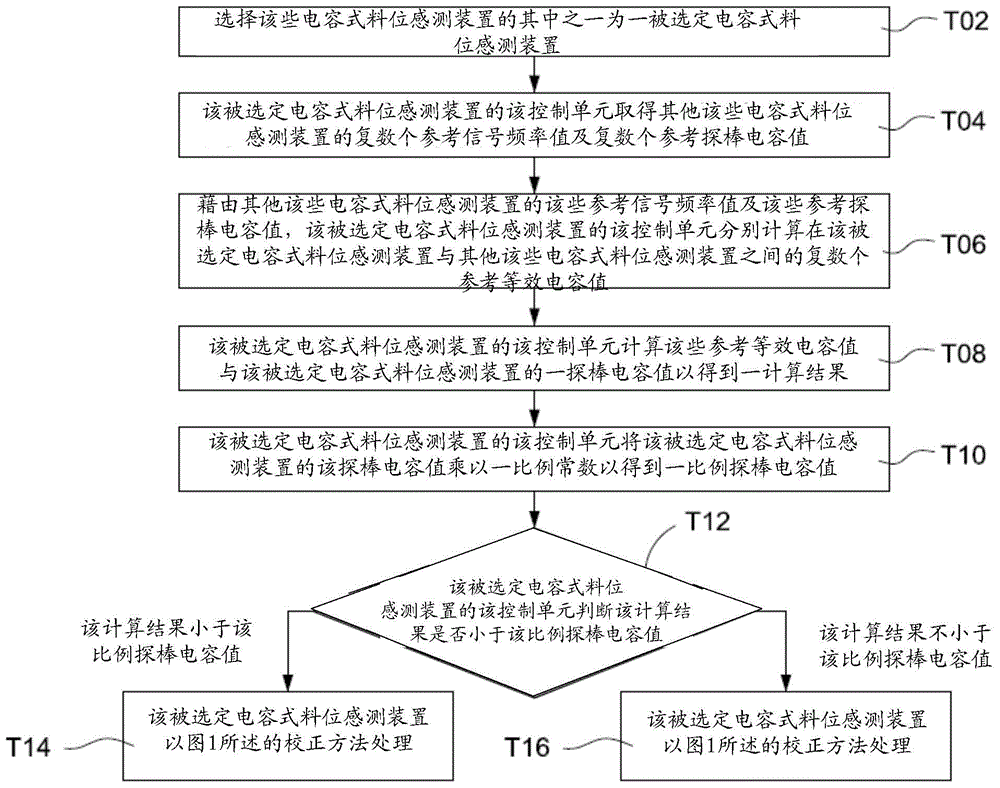

[0056] Please refer to figure 1 , Which is the flow chart of the calibration method of the capacitive level sensing device of the present invention; please also refer to figure 2 , Which is a block diagram of a capacitive level sensing device applying the calibration method of the present invention. A capacitive level sensing device 10 includes a measurement signal generating circuit 102, a sensing rod 106, a sensing circuit 108, and a control unit 112. The calibration method is applied to a barrel measurement, and the calibration method includes the following steps:

[0057] S02: The measurement signal generating circuit 102 generates a measurement signal 104 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com