T-slot tooling with universal quick-hold capability for shakers

A general-purpose, vibrating table technology, applied in the field of environmental testing, can solve the problem of not being able to quickly install and compact the test piece, and achieve the effects of efficient positioning and fast compaction, improved utilization, and strong versatility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

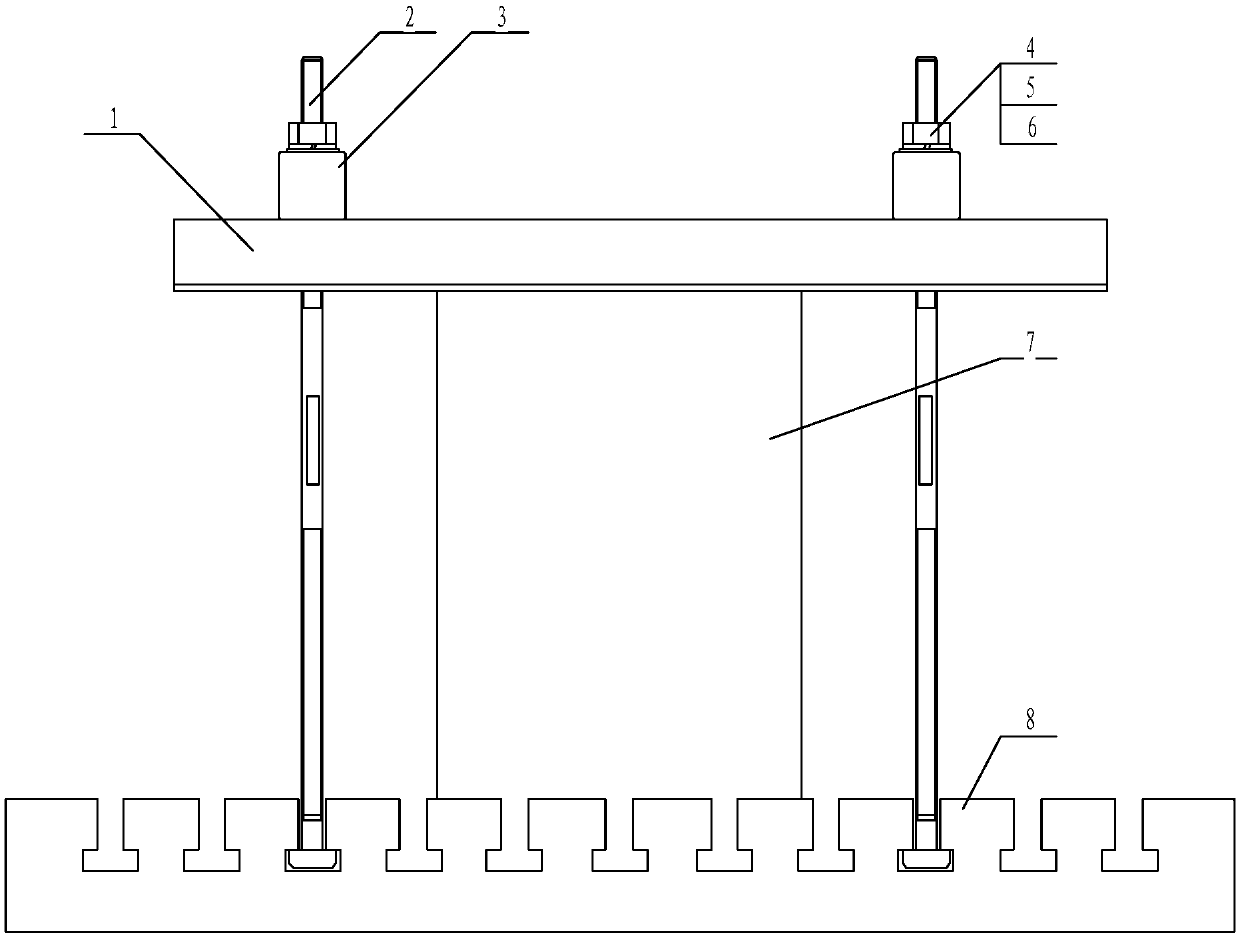

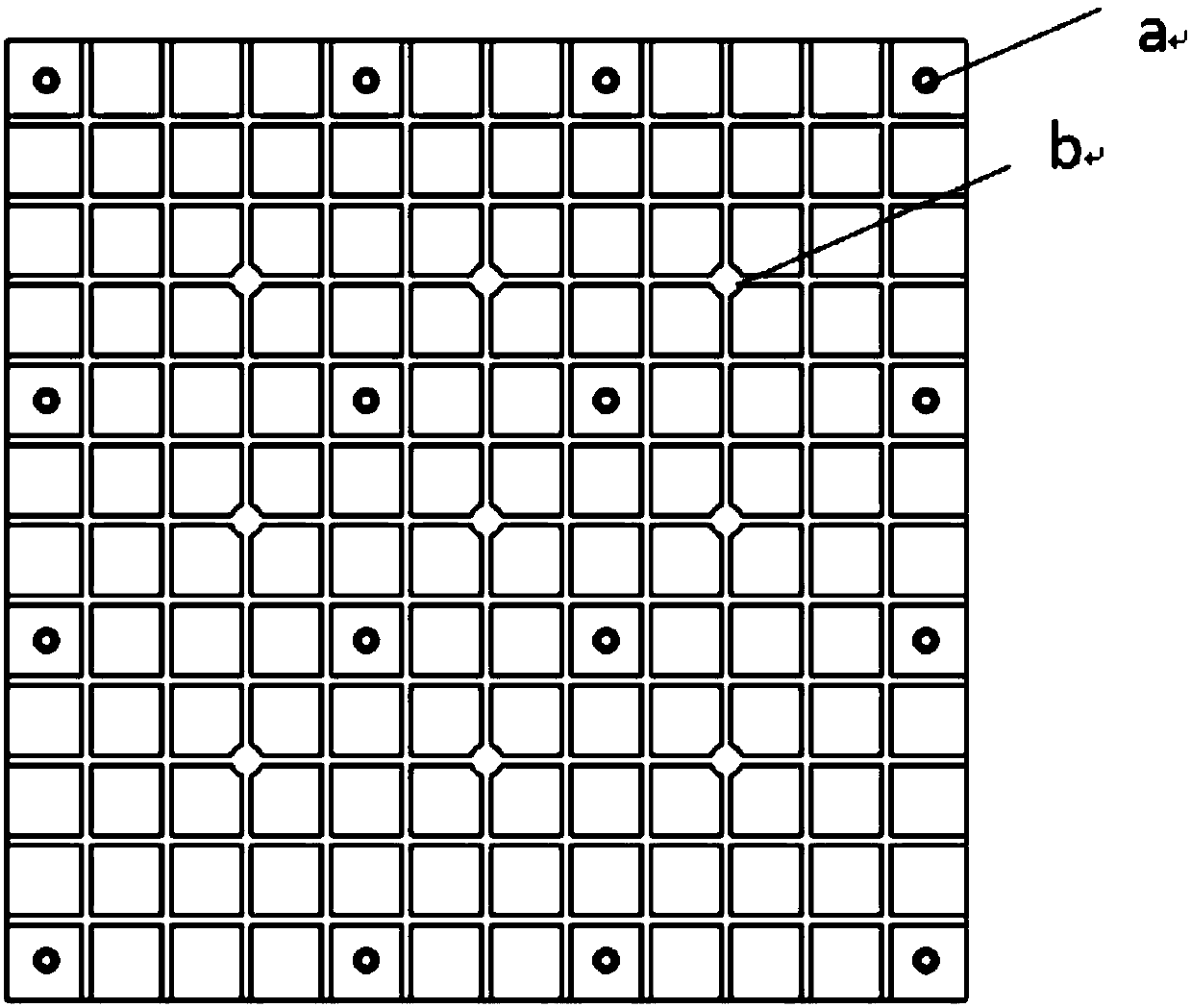

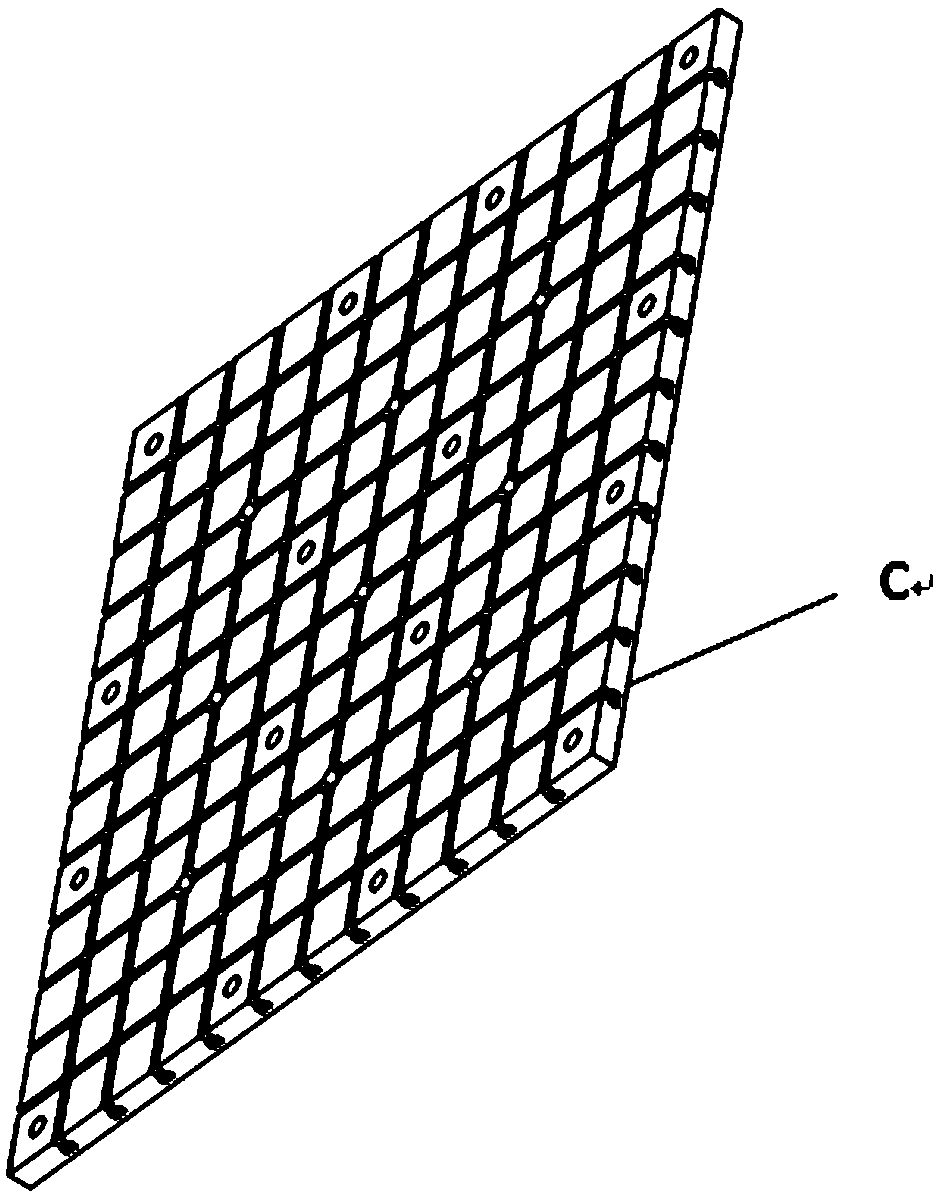

[0027] refer to figure 1 , the T-slot tooling with universal fast fixing ability in the embodiment of the present invention has a structure consisting of upper, middle and lower layers. Displacement in the direction of movement; the middle layer is a T-shaped screw 2 structural member, which bears tensile or shearing force, and the top passes through the U-shaped hole of the aluminum plate d to play a fixed role; the lower layer is a T-shaped groove plate 8, which plays a role of support and The effect of positioning the T-shaped screw rod 2, the cantilever beam structure connected with the T-shaped nut f bears a large bending moment. The T-slot tooling relies on U-shaped aluminum plate 1, T-screw 2, T-slot plate 8, n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com