Novel binding post bench free of tools

A terminal, tool-free technology, applied in the field of new tool-free terminal blocks, can solve the problems of falling off, insufficient volume, loose handle, etc., and achieve the effect of ensuring reliability and stable and reliable wiring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the present invention more obvious and understandable, the specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

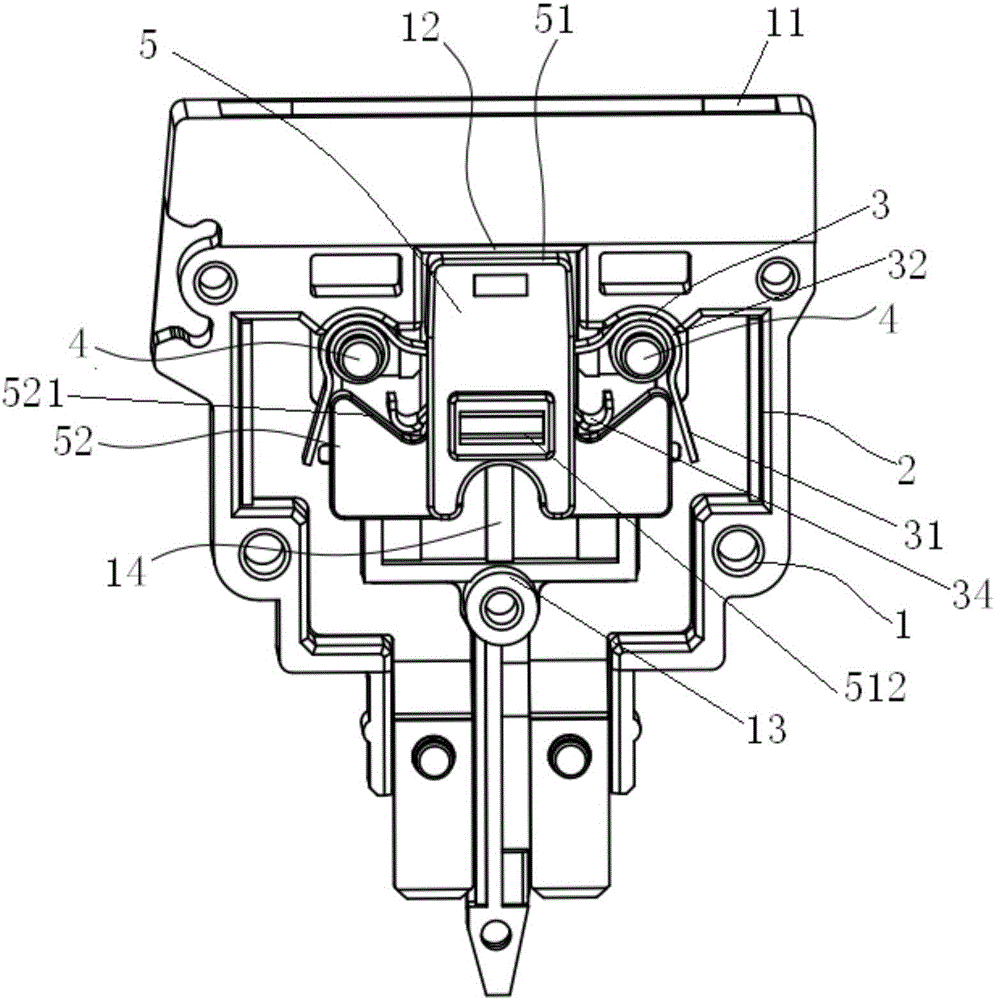

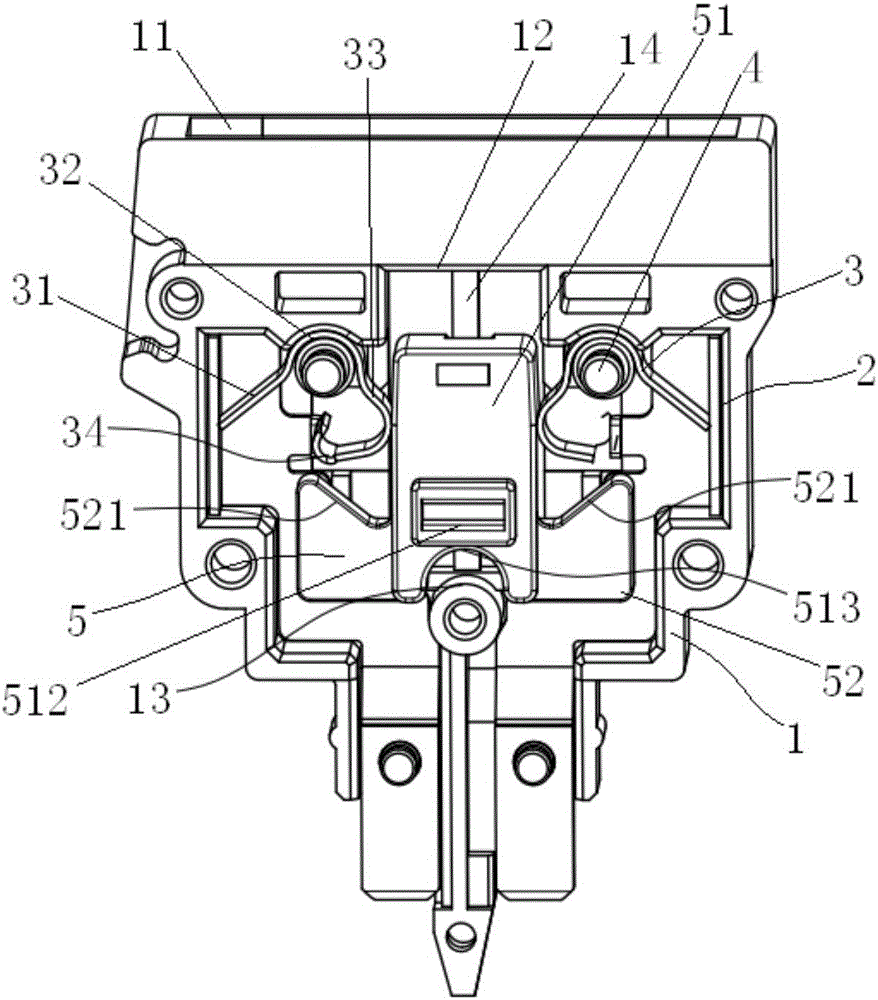

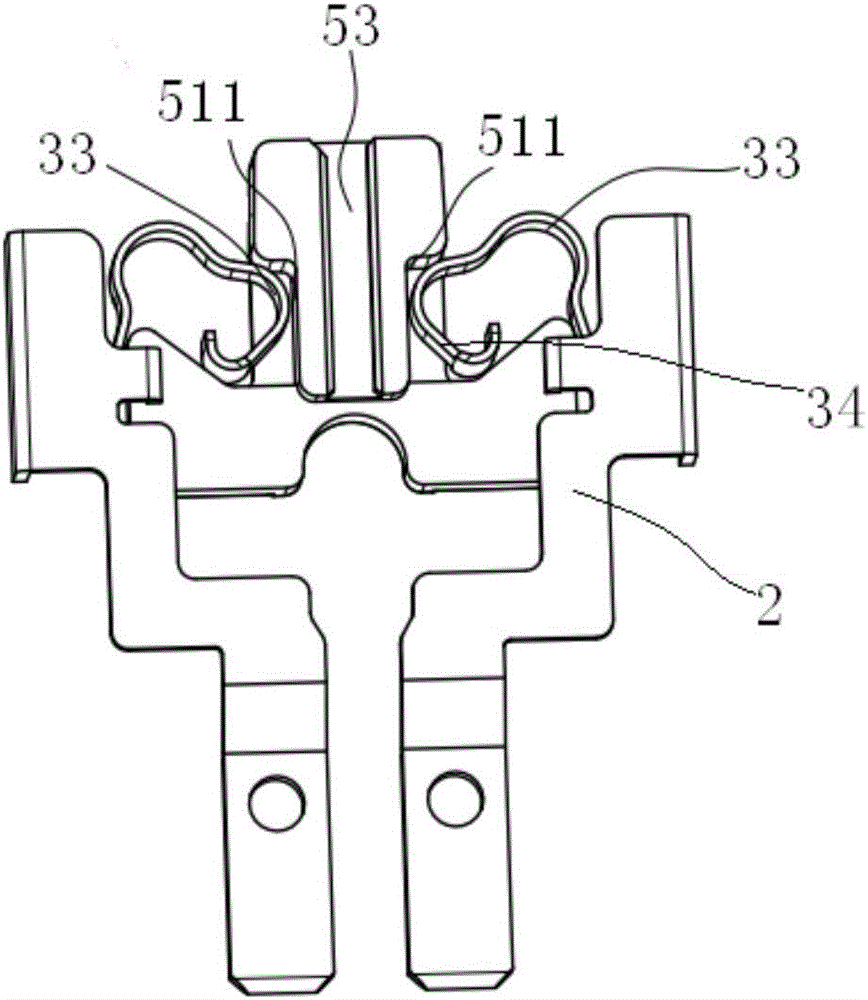

[0029] Such as figure 1 with figure 2 As shown, a new tool-free terminal block includes an insulating main body 1, at least one conductive terminal 2 positioned and installed on the insulating main body, and an elastic piece 3 corresponding to the conductive terminal, on the insulating main body The wire inlet 11 corresponding to the conductive terminal is provided, the elastic piece is rotatably positioned on the insulating main body through the rotating column 4, and the conductive terminal and the elastic piece are provided on the left and right sides of the wire inlet, The elastic piece includes a crimping arm 31, a mounting portion 32, a sliding arm 33, and a reset arm 34 formed by sequentially bending, and the mounting portion is mounted on the rotating column; and al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com