Peanut harvester

A peanut harvester and rack technology, which is applied to excavator harvesters, harvesters, agricultural machinery and implements, etc., can solve the problems that sandy soil cannot be taken away, implements cannot work normally, and the gap between conveyor chains and ladders is large. Achieve the effect of reducing fruit drop loss, simple structure and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

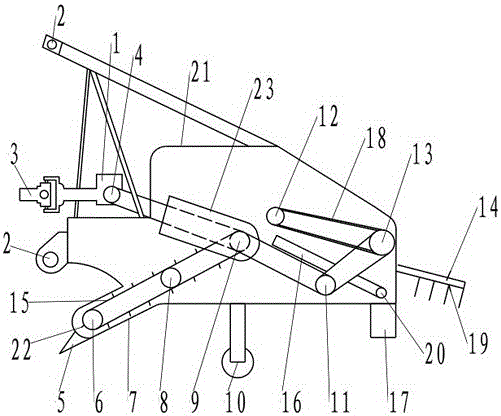

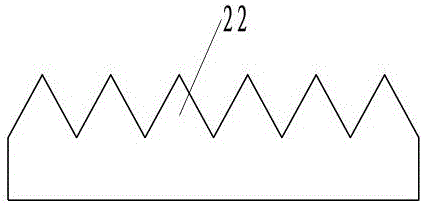

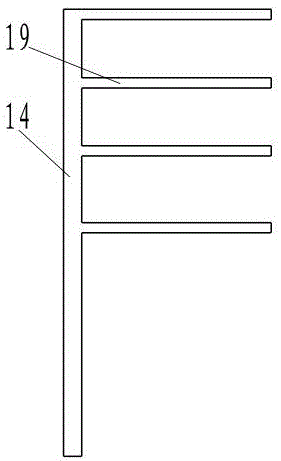

[0014] attached figure 1 Be the specific embodiment of the present invention, comprise frame 21, be arranged on the suspension device 2 of frame 21 front end, be installed in the ground pressing wheel 10 of frame 21 bottom, be installed in the blade 5 of frame 21 front end bottom, blade 5. After the conveyor belt device is connected, the conveyor belt device is connected to the conveyor chain ladder device. It is characterized in that: the conveyor belt device includes a conveyor belt 15, a conveyor belt bracket 7, a conveyor belt power wheel 9, a conveyor belt tensioner 8 and a conveyor belt. With rotating shaft 6, wherein, such as figure 2 , the conveyor belt 15 is equipped with a zigzag baffle 22 perpendicular to its moving direction; the conveyor chain ladder device includes a conveyor chain ladder power wheel 13, a conveyor chain ladder 18 and a conveyor chain ladder driven wheel 12; also includes a vibrating screen 16. The eccentric shaft power wheel 11 connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com