Construction waste crushing system light material collector

A crushing system and construction waste technology, applied in grain processing, etc., can solve the problems of high labor intensity, low picking efficiency, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

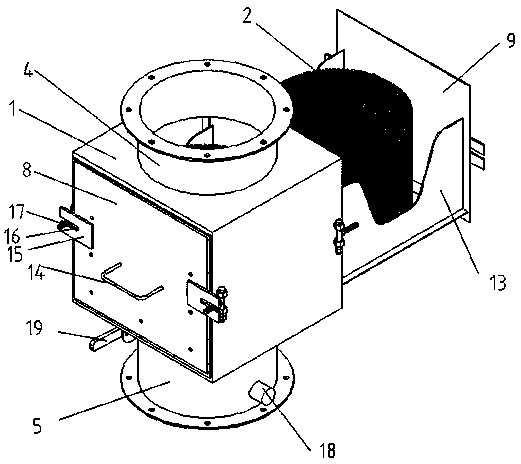

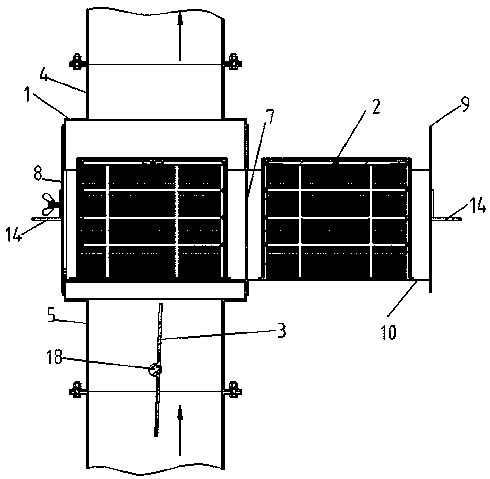

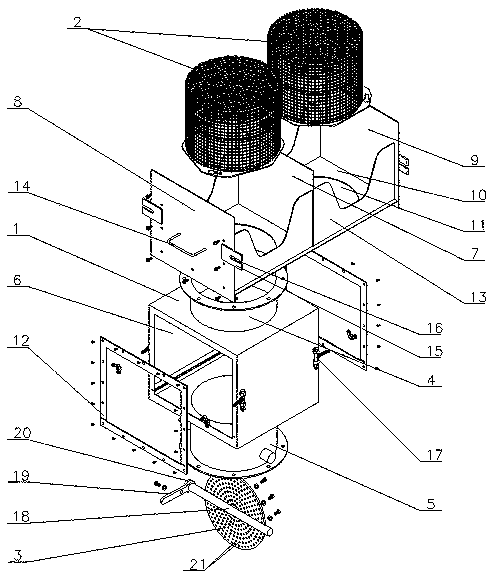

[0013] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0014] As shown in the figure, the light material collector of the construction waste crushing system of the present invention includes a box body 1, a drawer, a butterfly plate 3 and a filter cartridge 2 installed in the box body 1, and an upper connecting cylinder 4 is arranged above the box body 1. In order to connect the dust collection pipeline, a lower connecting cylinder 5 is provided under the box body 1 for connecting the dust collection pipeline. Openings 6 are arranged symmetrically on the left and right sides of the box body 1, and a drawer is installed between the two openings 6. Described drawer comprises left panel 8, right panel 9 and the base plate 10 that is connected between left panel 8 and right panel 9 lower ends, is provided with two circular holes 11 symmetrically on base plate 10, is provided with in the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com