Device for detecting rim flatness

A flatness and rim technology, which is applied in the field of devices for detecting the flatness of the rim, can solve the problems of reducing the rim flatness correction efficiency, increasing the operator's work intensity, poor rim flatness, etc., to save production costs, reduce work intensity, The effect of improving the calibration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

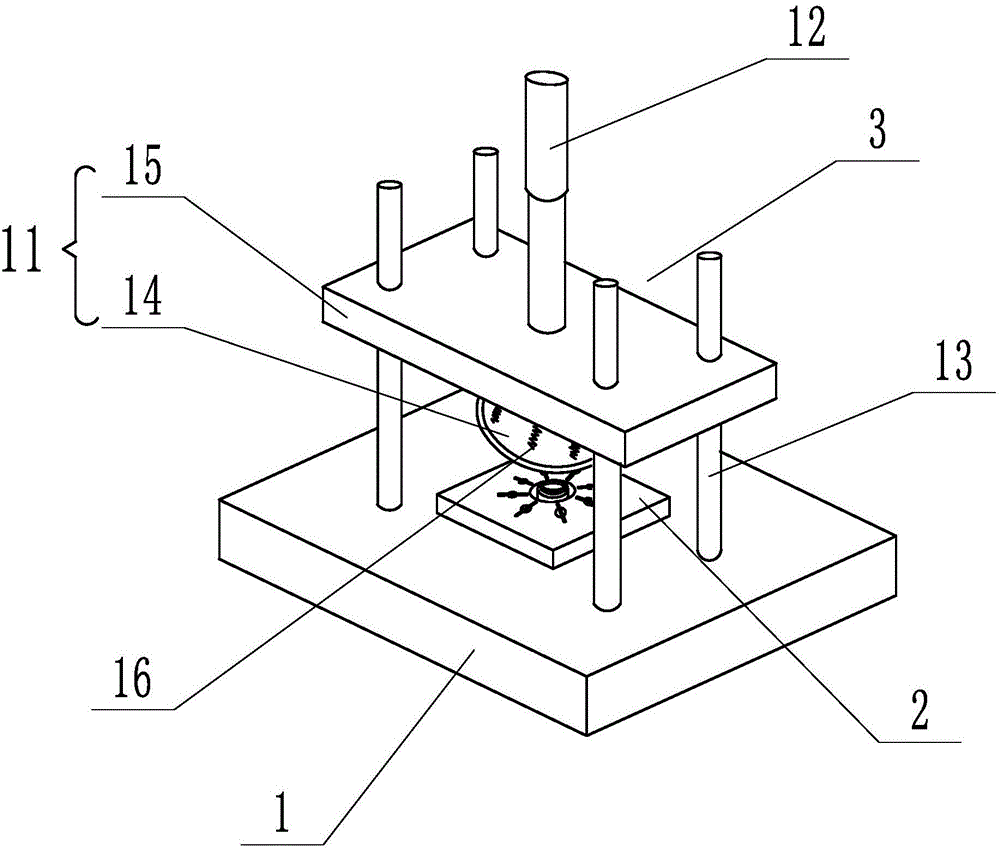

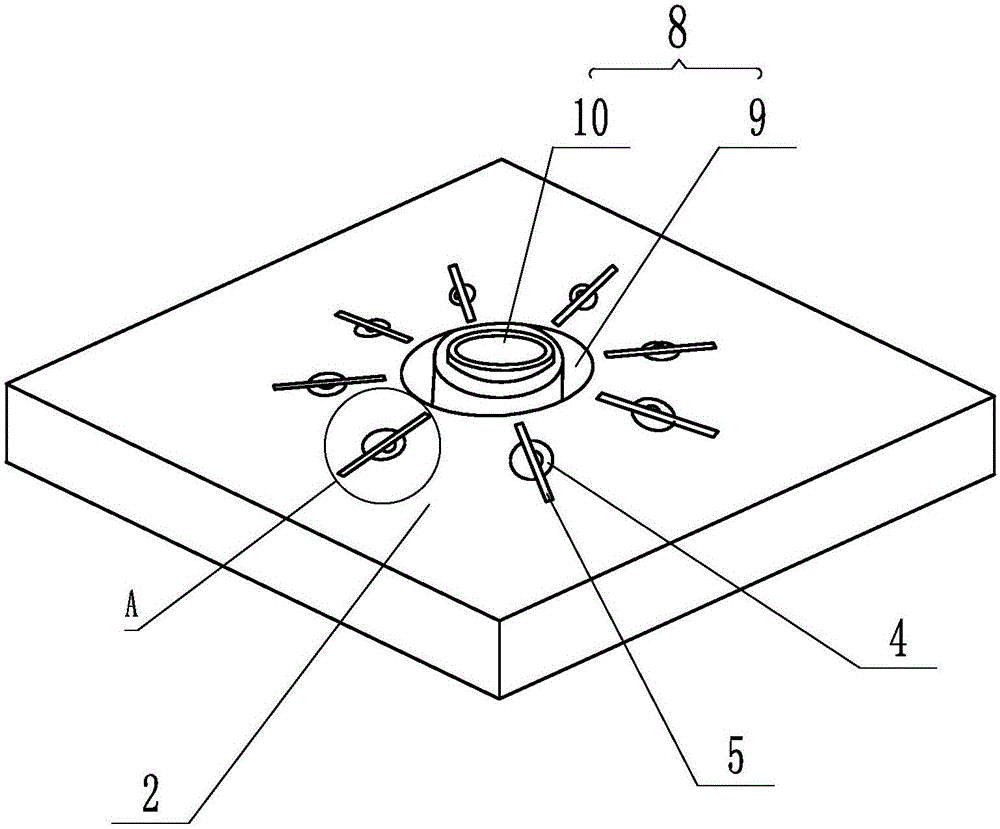

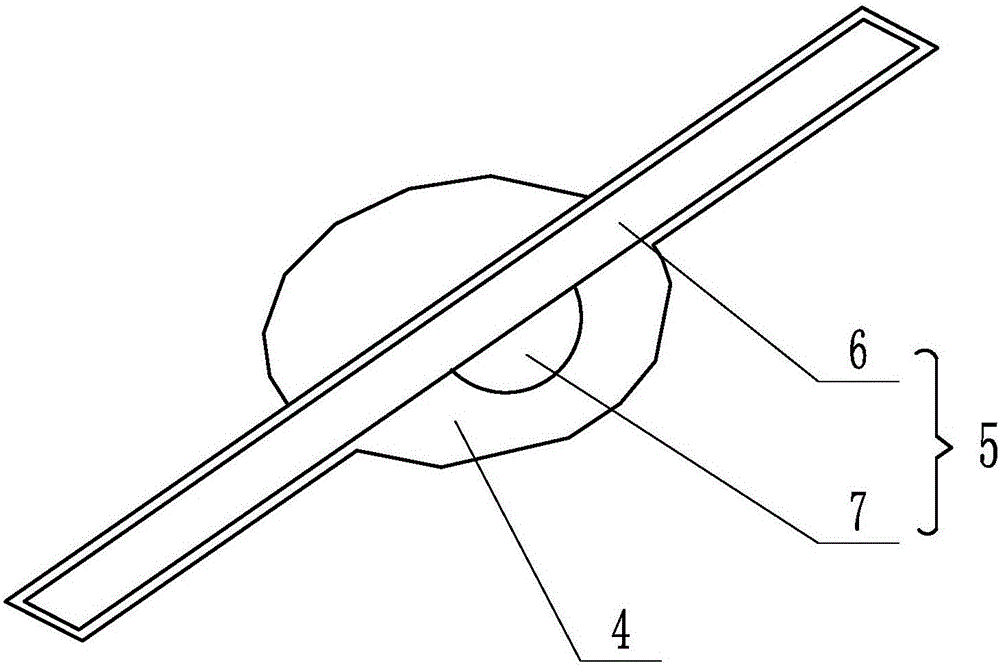

[0019] Such as figure 1 , figure 2 and image 3 As shown, a device for detecting the flatness of the rim includes a frame 1, and a stamping platform 2 and a stamping unit 3 arranged on the frame 1 to correct the flatness of the rim, and the stamping platform 2 is provided with several first grooves 4. The first groove 4 is provided with a detection unit 5 for detecting the flatness of the rim of the wheel. The detection unit 5 includes a detection piece 6 that is slidably connected with the first groove 4. A pressure sensing device 7 is fixedly installed on the detection piece 6 to detect The piece 6 slides in the direction perpendicular to the stamping platform 2 to place the wheel on the stamping platform 2, and the flatness of the wheel rim is corrected by the stamping unit 3. After the correction is completed, the detection piece 6 automatically faces in the first groove 4. The rim slides a certain distance, so that the pressure sensing device 7 arranged on the detectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com