Hip joint assembly of simulation intelligent robot

An intelligent robot and hip joint technology, applied in the field of robotics, can solve the problems of large volume, low simulation degree and complex structure of the hip joint, and achieve the effects of compact and simple structure, high simulation degree and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

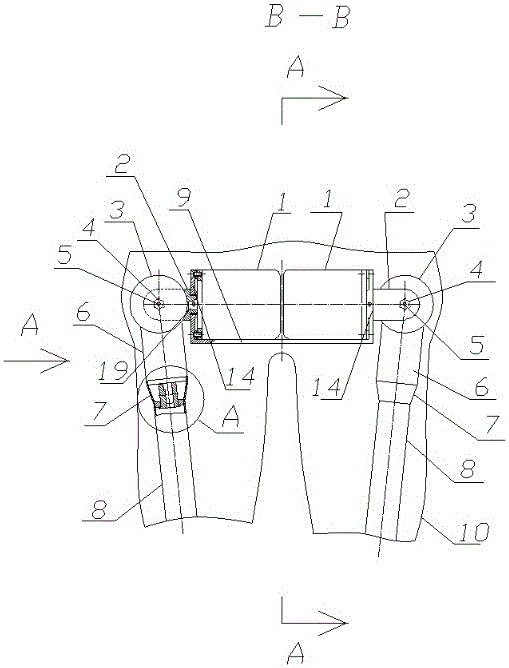

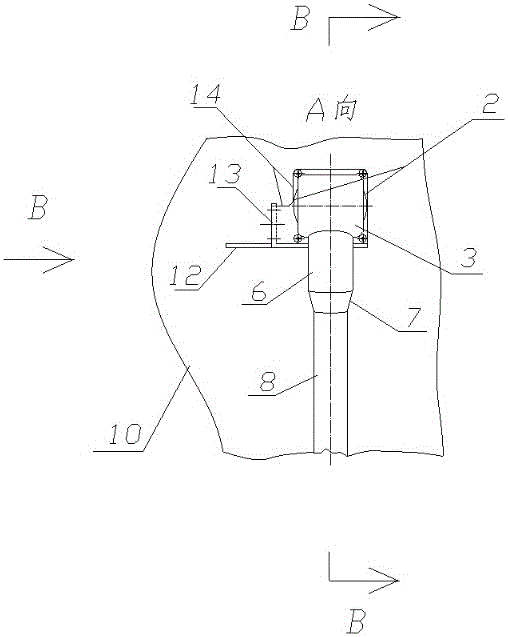

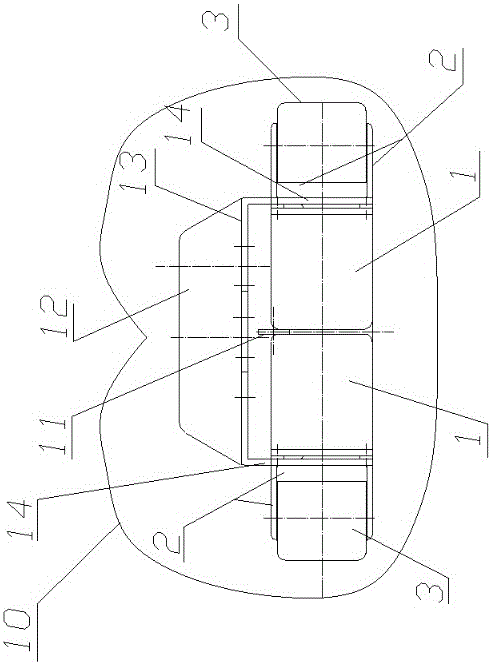

[0018] It can be clearly seen from the figures of the specific embodiments that the present invention includes a hip joint base frame 9, a thigh front and rear swing motor 1 positioned on the left and right side panels 14 in the hip joint base frame 9, and a thigh swing motor 1 positioned on the front and rear swings of the two thighs. The rotating fork 2 on the motor output shaft 19, the two left and right thigh swing motors 3 and the thigh rotating motor 6 are motors with an integrated structure, and the two left and right thigh swing motors 3 and the thigh rotating motor 6 are integrated structure motors. The central output shaft 4 at both ends of the motor is positioned on the rotary fork 2, and is respectively positioned on the output shaft 19 of the two thigh front and rear swing motors 1 through the rotary fork 2. The left and right thigh swing rotation integrated structure motor has a shell of Integrated structure, the output shaft 4 of the left and right thigh swing mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com