Multi-color mosaic symmetric-distributed automatic paving equipment

A mosaic and distributed technology, applied in the direction of decorative art, decorative structure, etc., can solve the problems of low mosaic automation and low production efficiency, and achieve the effect of improving the efficiency and speed of laying and improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

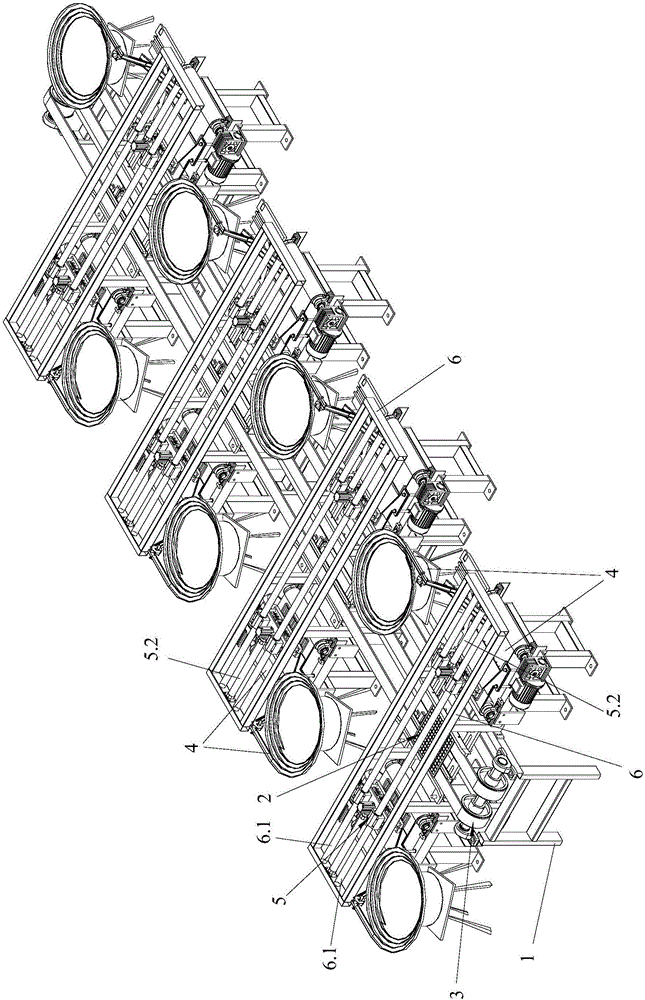

[0063] The symmetrical distributed automatic paving equipment of the multi-color mosaic of the present embodiment adopts eight mosaic automatic feeding units, and each mosaic automatic feeding unit corresponds to the feeding of a color mosaic, and the mosaic in the eight mosaic automatic feeding units Colors are repeatable.

[0064] Such as Figures 1 to 11 As shown, a symmetrical distributed automatic paving equipment for multi-color mosaics is used for orderly paving according to preset patterns; including:

[0065] pedestal 1;

[0066] A mosaic tire mold transmission mechanism 3 for transmitting the mosaic tire mold 2 along the length direction of the base frame 1, and the mosaic tire mold transmission mechanism 3 is arranged on the base frame 1;

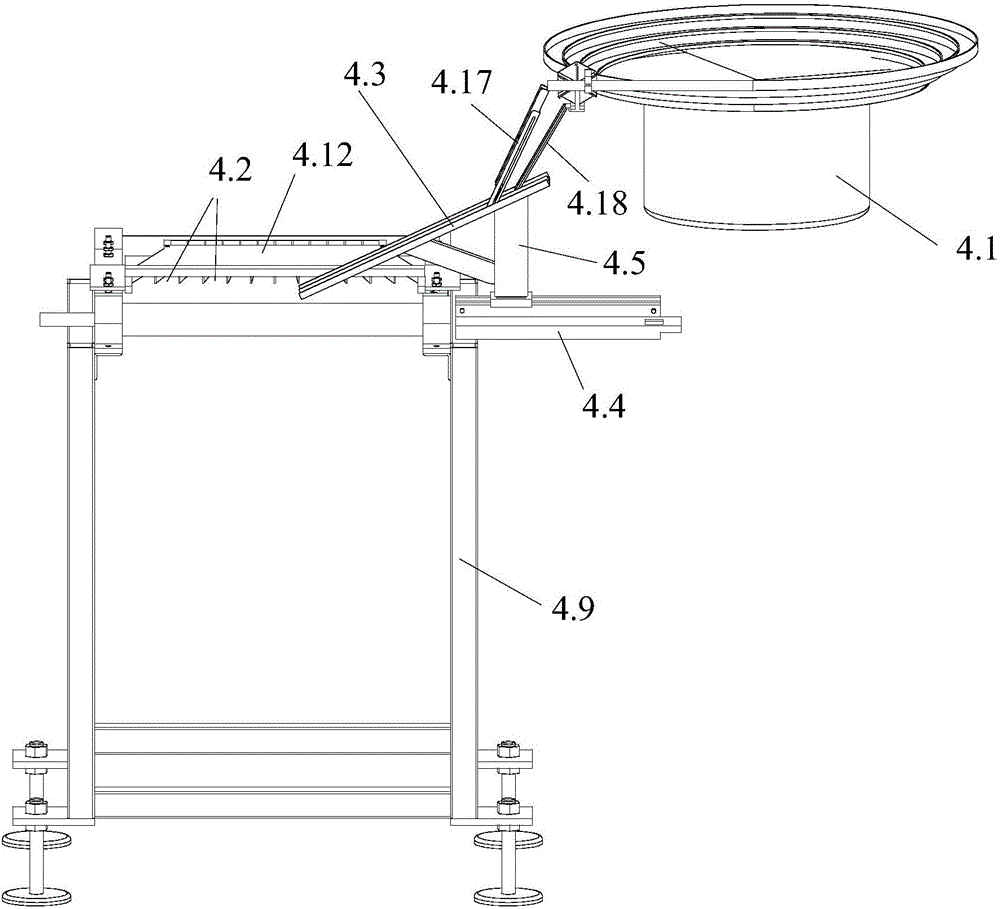

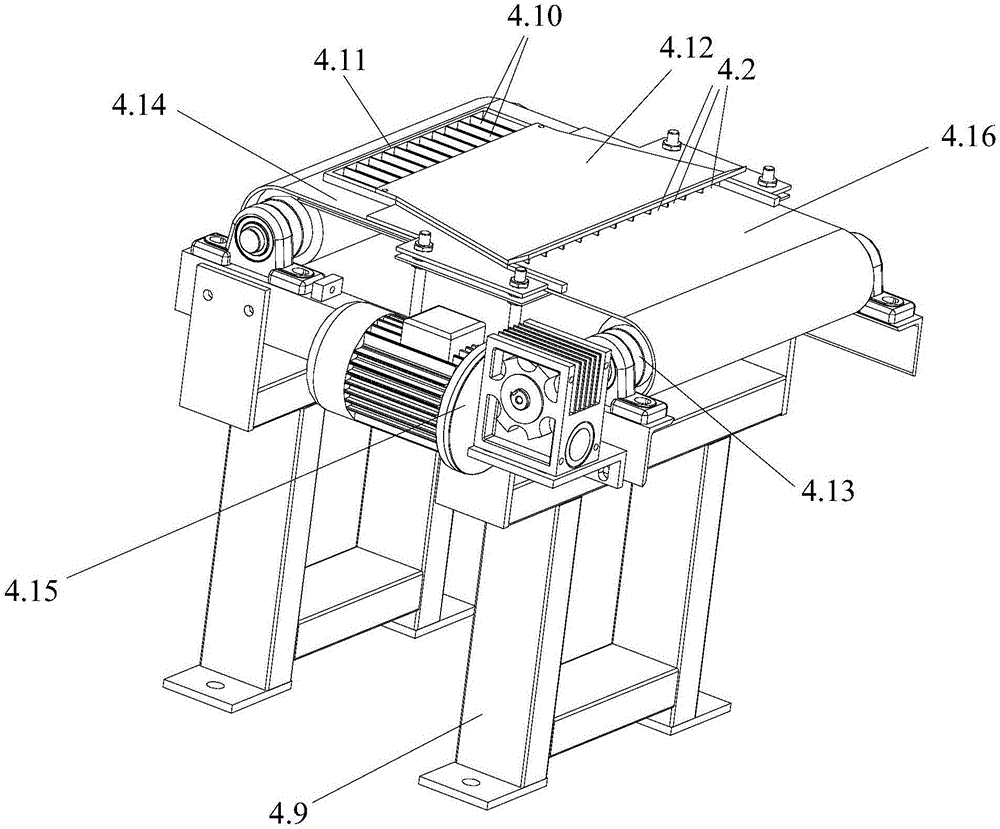

[0067] Eight multi-color mosaic automatic feeding units arranged on both sides of the base frame 1 are symmetrically distributed along the length direction of the base frame 1; wherein each mosaic automatic feeding unit is used...

Embodiment 2

[0096] The only difference between this embodiment and Embodiment 1 is that the rotating disk is a rotating disk with cavities evenly divided, and its cavities can be set to 4, 5 or 7, etc. One side of the feed port can be evenly distributed around the circumference.

[0097] Other structures of this embodiment are consistent with Embodiment 1.

Embodiment 3

[0099] The only difference between this embodiment and Embodiment 1 is that the feeding mechanism of this embodiment can be provided with three or more suction cup frames, and adjacent suction cup frames are provided with a partition device for separating adjacent suction cup frames, so that The distance between two adjacent rows of absorbed mosaics is the same as the distance between two adjacent rows / columns of mosaic tire molds.

[0100] Other structures of this embodiment are consistent with Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com