An active vibration suppression method for range extender startup based on crankshaft stop position control

A range extender and crankshaft technology, applied in the direction of control devices, etc., can solve problems such as uncomfortable driving feeling and vibration, and achieve the effect of improving accuracy, good control effect and suppressing vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

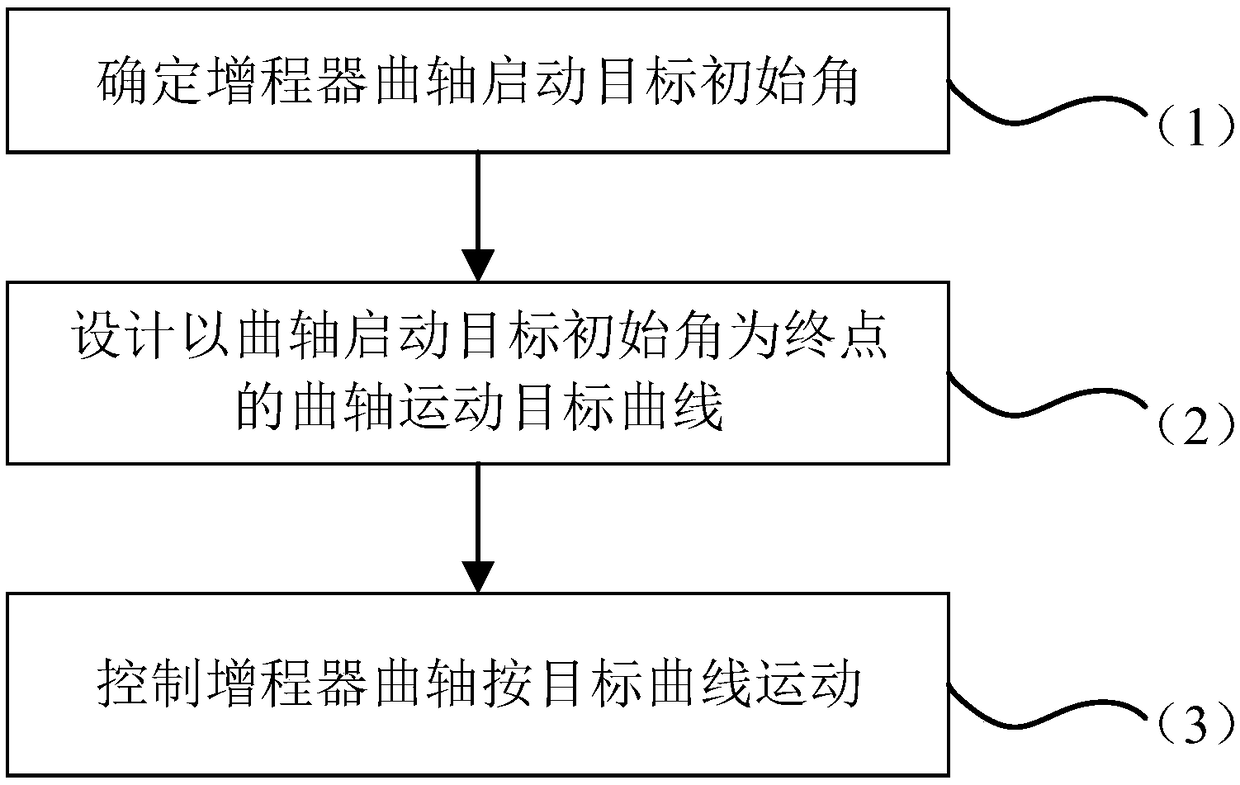

[0038] Such as figure 1 As shown, a range extender startup active vibration suppression method based on crankshaft stop position control, the method is:

[0039] (1) Establish the crankshaft start target initial angle that makes the range extender suspension system minimum excitation to the vehicle body;

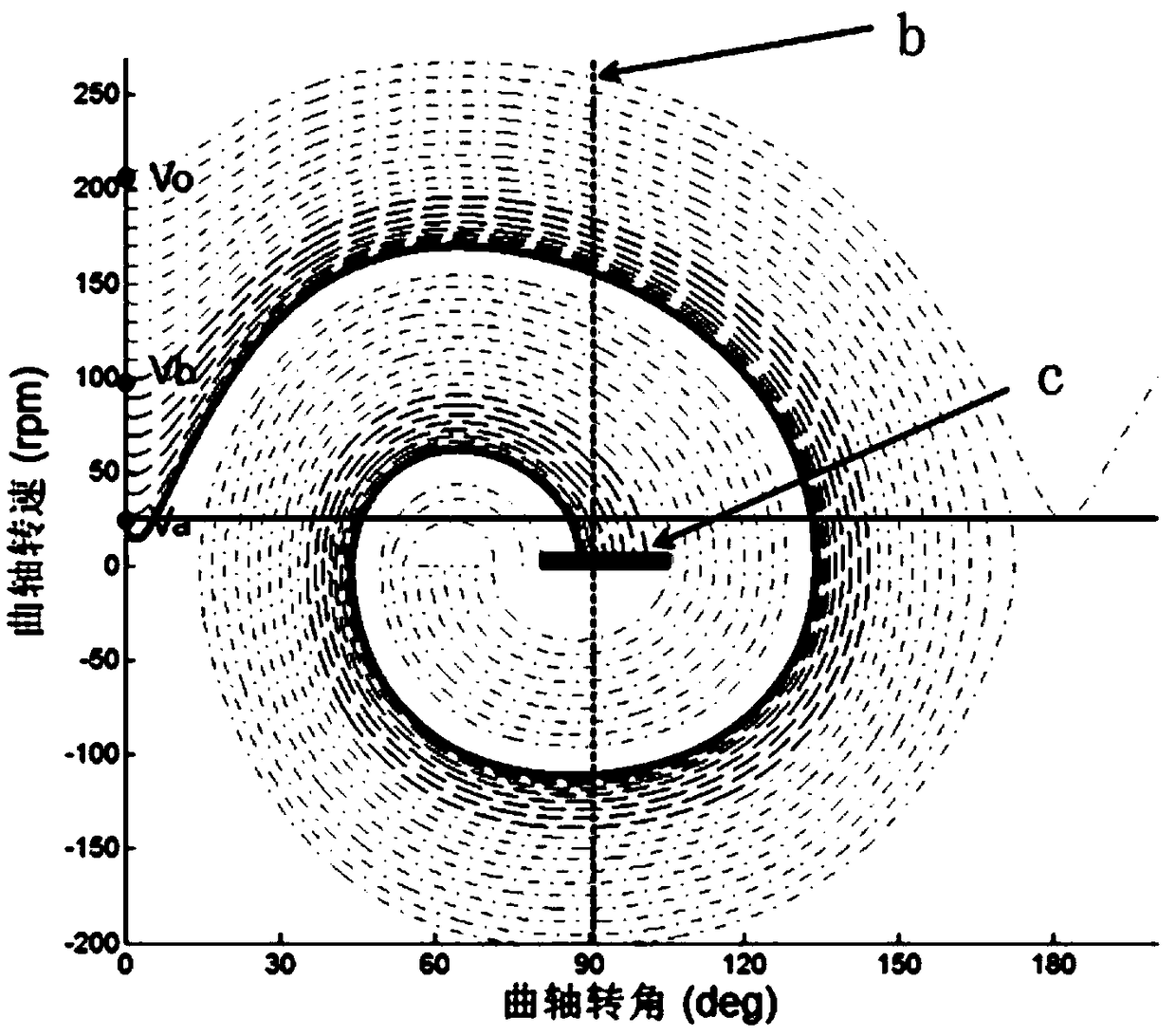

[0040] (2) Design the crankshaft motion target curve with the crankshaft starting target initial angle as the end point;

[0041] (3) During the shutdown process of the range extender, the crankshaft is controlled to move to the end point according to the crankshaft movement target curve, so that the next time the range extender is started, the crankshaft is at the crankshaft start target initial angle in step (1), and the range extender suspension system has a positive impact on the vehicle body The excitation is the smallest, and the vibration of the range extender is suppressed at startup.

[0042] Step (1) is specifically:

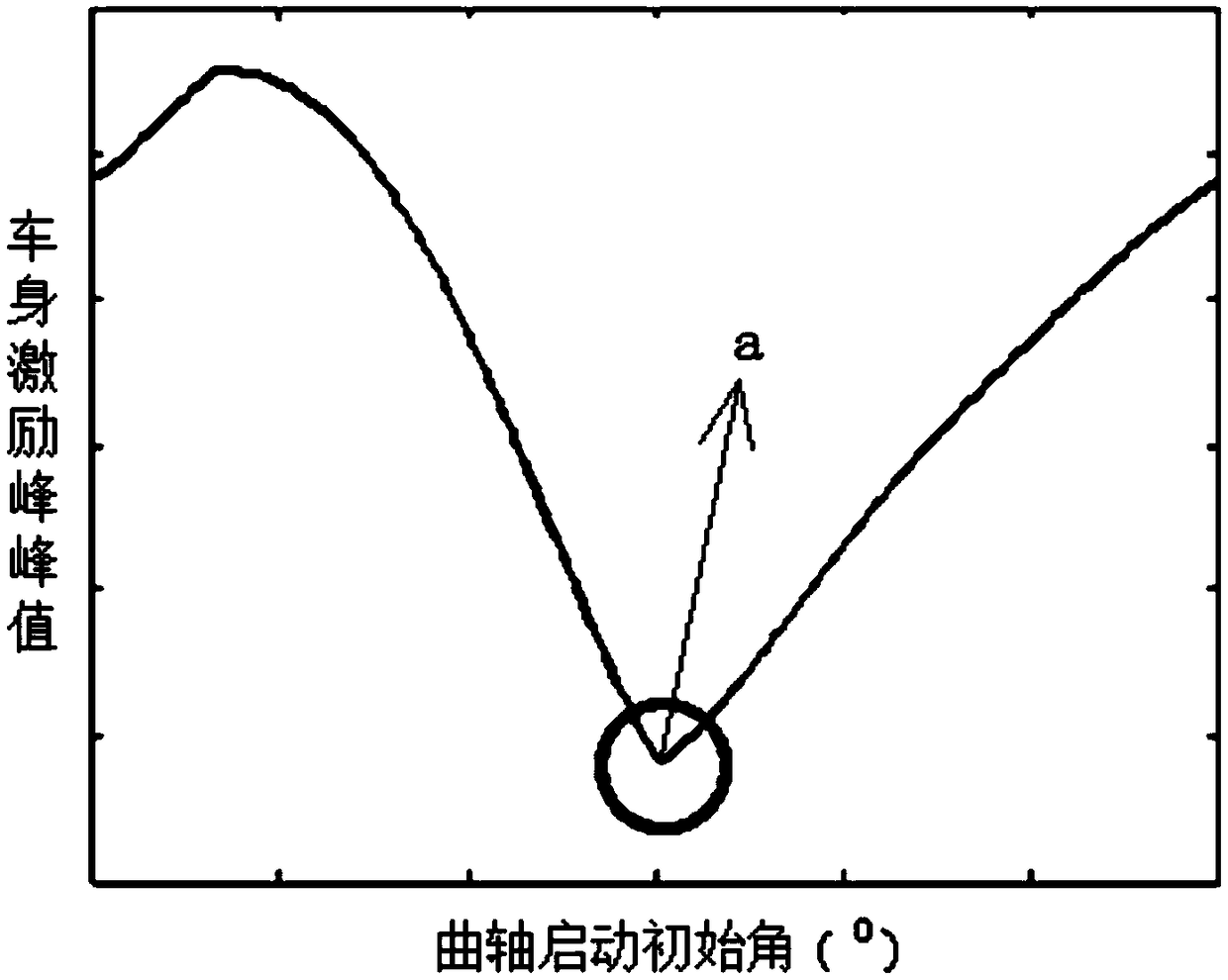

[0043] (101) Run the range extender at diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com