Automatic PE bag packaging machine

An automatic packaging machine and rack technology, applied in the field of machinery, can solve the problems of inability to effectively guarantee the operating environment, affect the safety of medical supplies, low work efficiency, etc., and achieve labor cost savings, good product consistency, and improved packaging efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

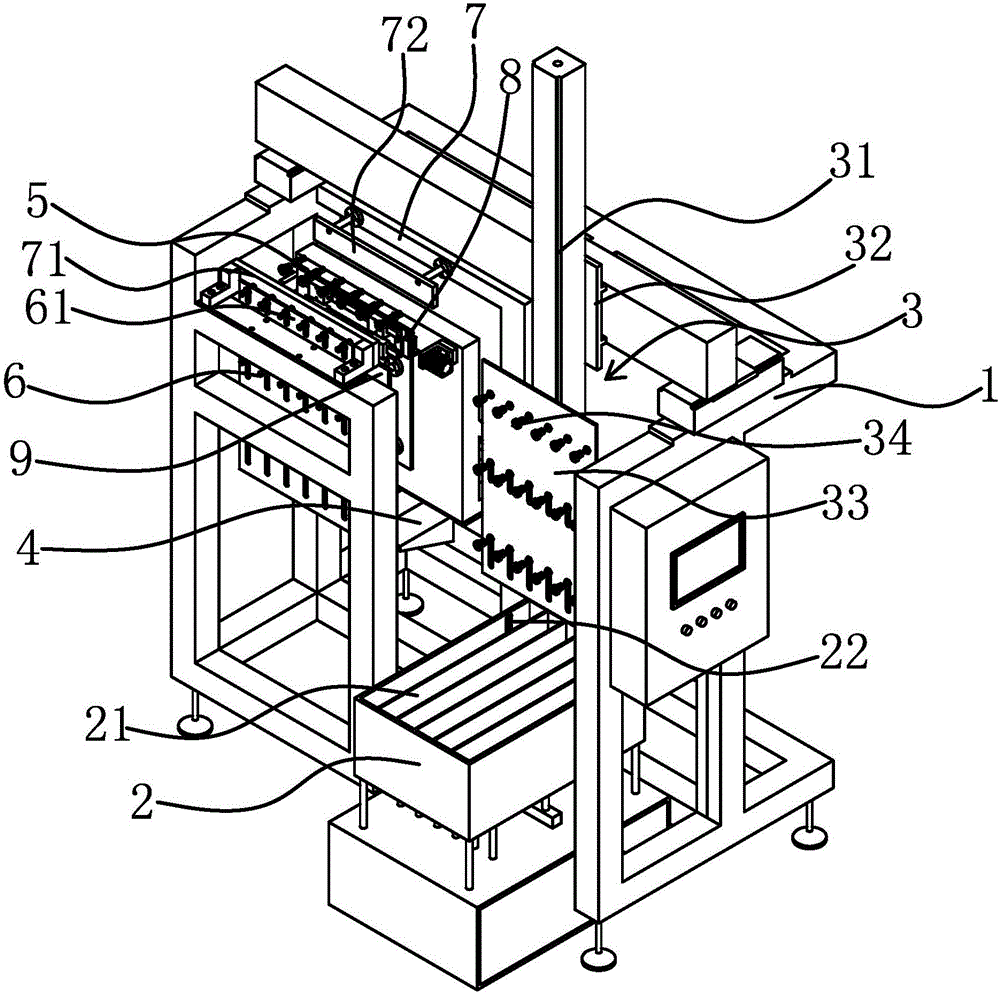

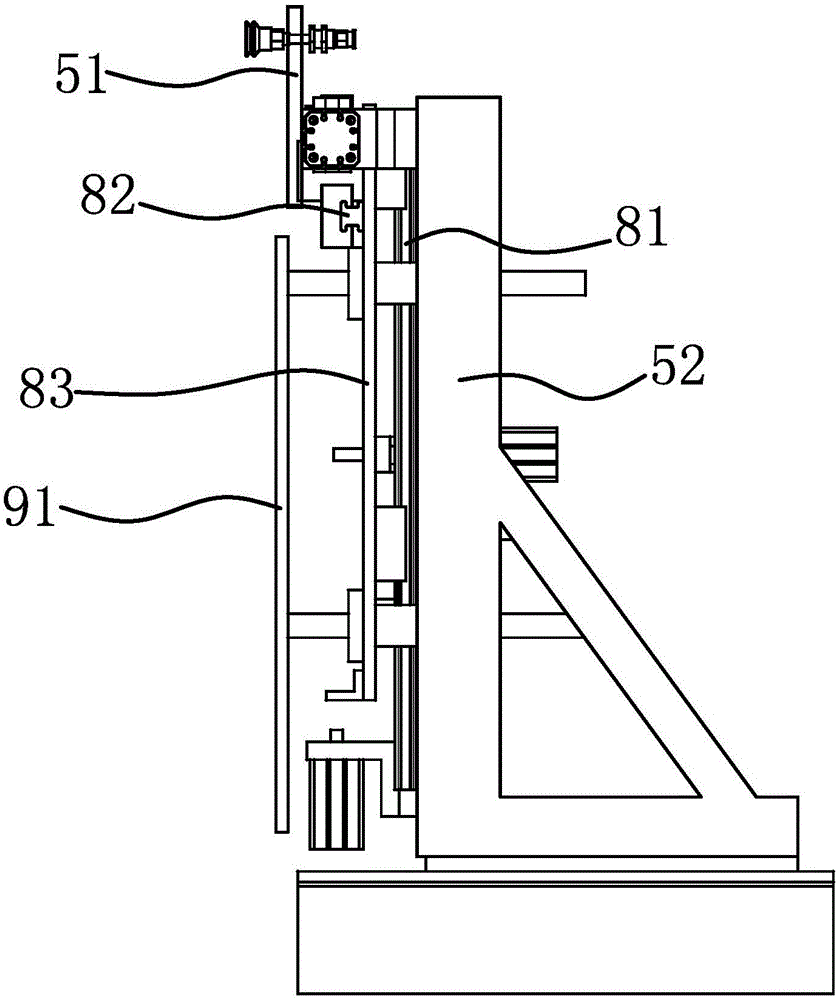

[0031] Such as figure 1 and figure 2As shown, the PE bag automatic packaging machine includes a frame 1, a trough 2 is provided at the bottom of the frame 1, a negative pressure retrieving device 3 for absorbing one side of the PE bag is provided above the trough 2, and a driving device 3 is provided above the frame 1. The lifting device 31 that the negative pressure reclaiming device 3 rises and falls and the lateral movement device 32 that drives the negative pressure reclaiming device 3 to move left and right, the frame 1 is also provided with a fixing device 6 for adsorbing the other side of the PE bag and for Pull open the bag opening device 5 of bag opening, also be provided with on the frame 1 and be used for carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com