A horizontal transport chain for wood

A horizontal transportation and chain technology, applied in the field of conveyor chains, can solve the problems of wood damage and poor synchronization of multiple chains, and achieve the effect of preventing asynchrony, ensuring synchronization and preventing damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

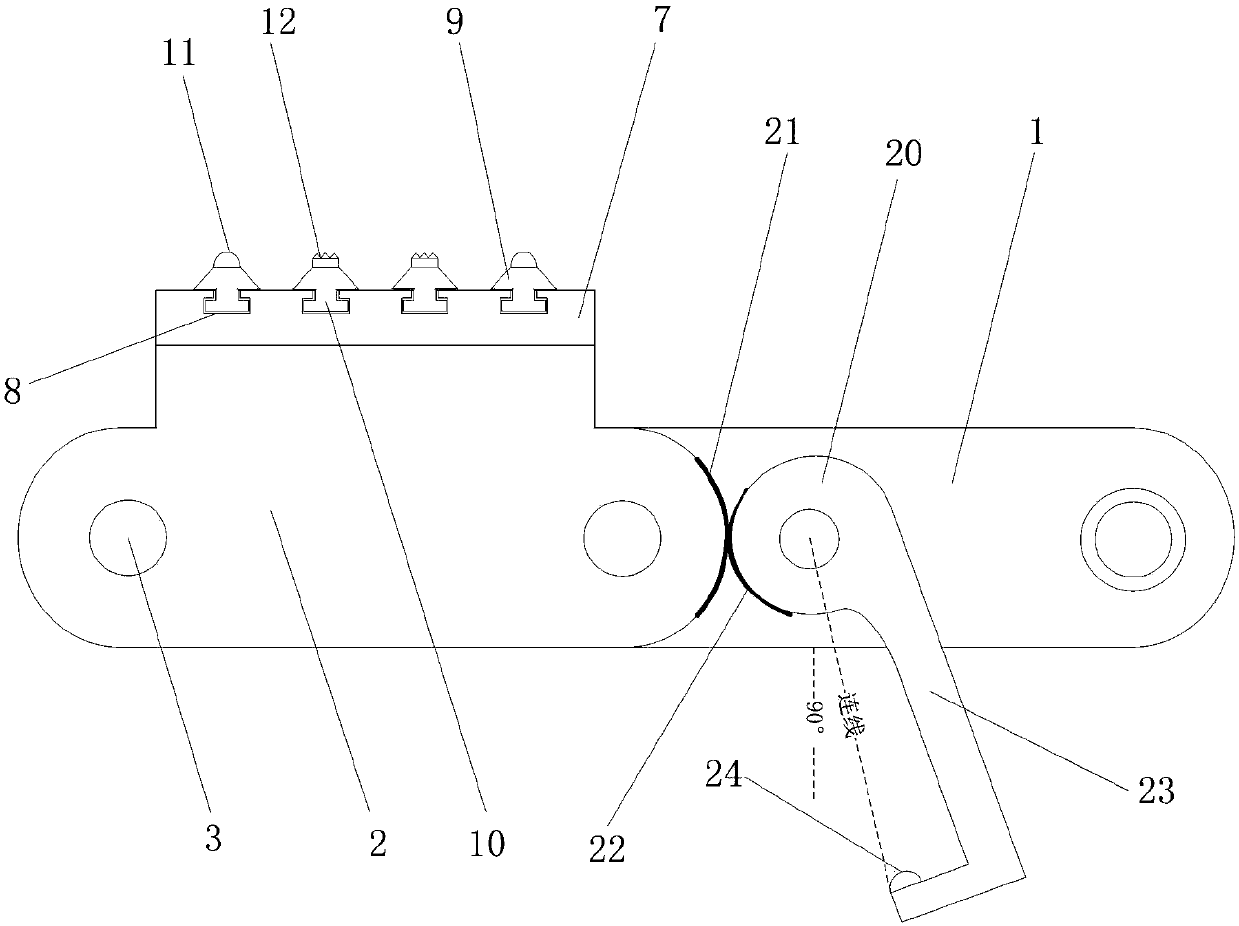

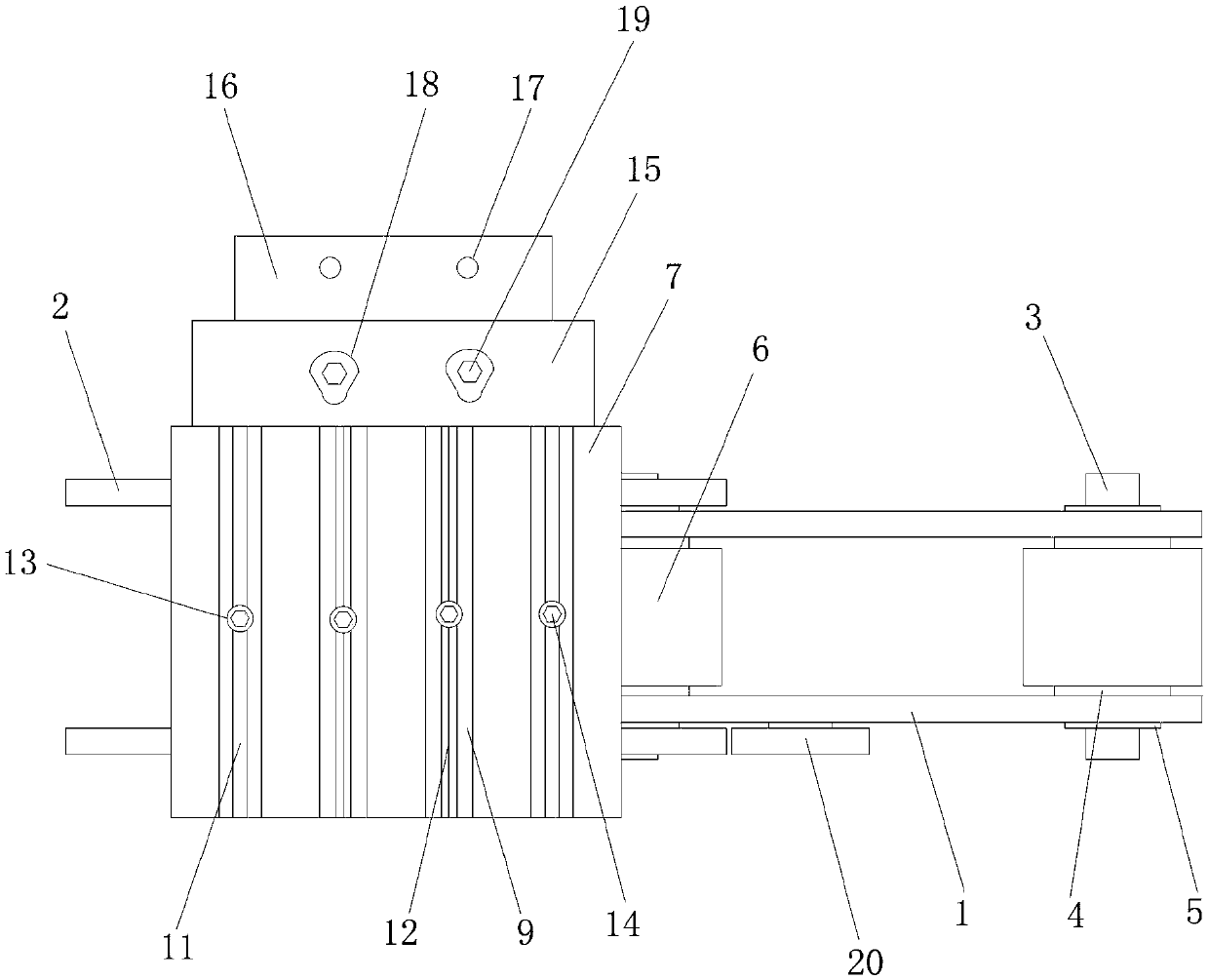

[0039] Such as figure 1 and 2 As shown, the present invention discloses a horizontal transport chain for timber, which is composed of chain links connected in sequence; each chain link includes two inner chain plates 1, two outer chain plates 2, two rollers 6, Two sleeves 4, two pin shafts 3, a support plate 7, two edge anti-slip strips, at least one middle anti-slip strip, a side extension connection mechanism and an anti-skid mechanism;

[0040] The two inner chain plates 1 are arranged in parallel and facing each other;

[0041] The two sleeves 4 are arranged in parallel on the two inner chain plates 1, and a circle of limiting convex rings is provided on the outer circumference of the sleeves 4;

[0042] The two rollers 6 are sleeved on the two sleeves 4 respectively, and a limit groove is provided on the inner circumference of the rollers 6;

[0043] The said limiting protruding ring is embedded in the limiting groove, and can be rotated relatively, and the position of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com