Material pushing device of sorting machine

A technology of a pushing device and a sorter, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of low pushing efficiency, prone to misoperation, and high cost, and achieves high pushing efficiency, improved accuracy, Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

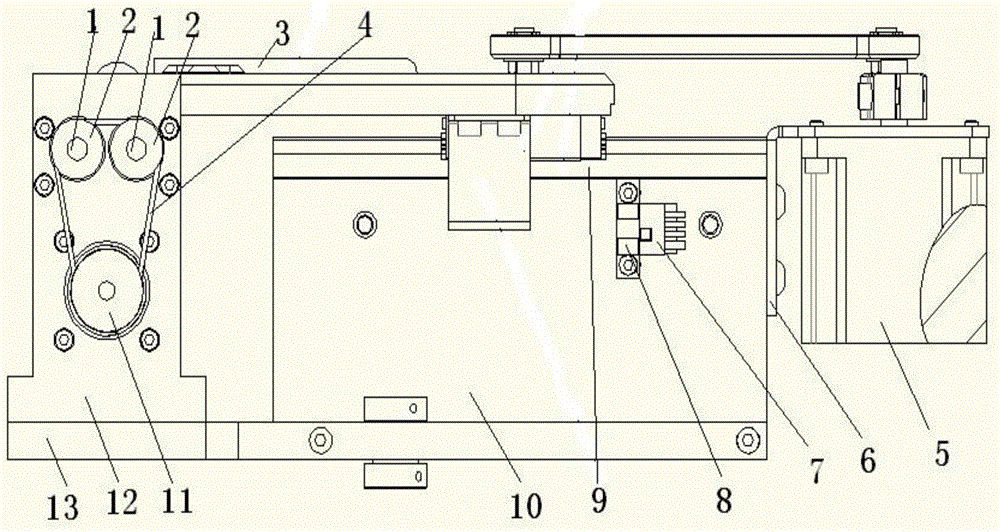

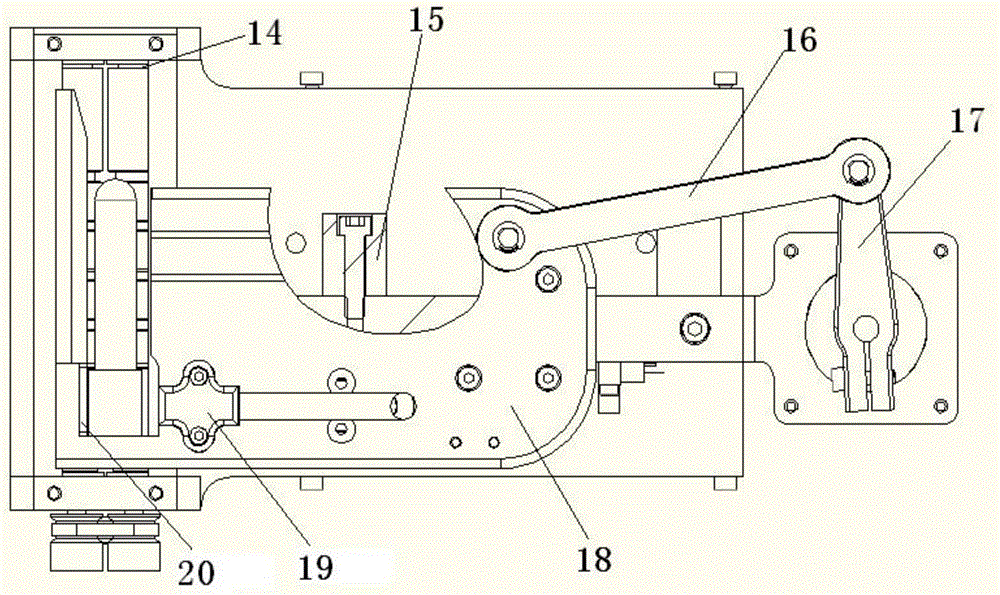

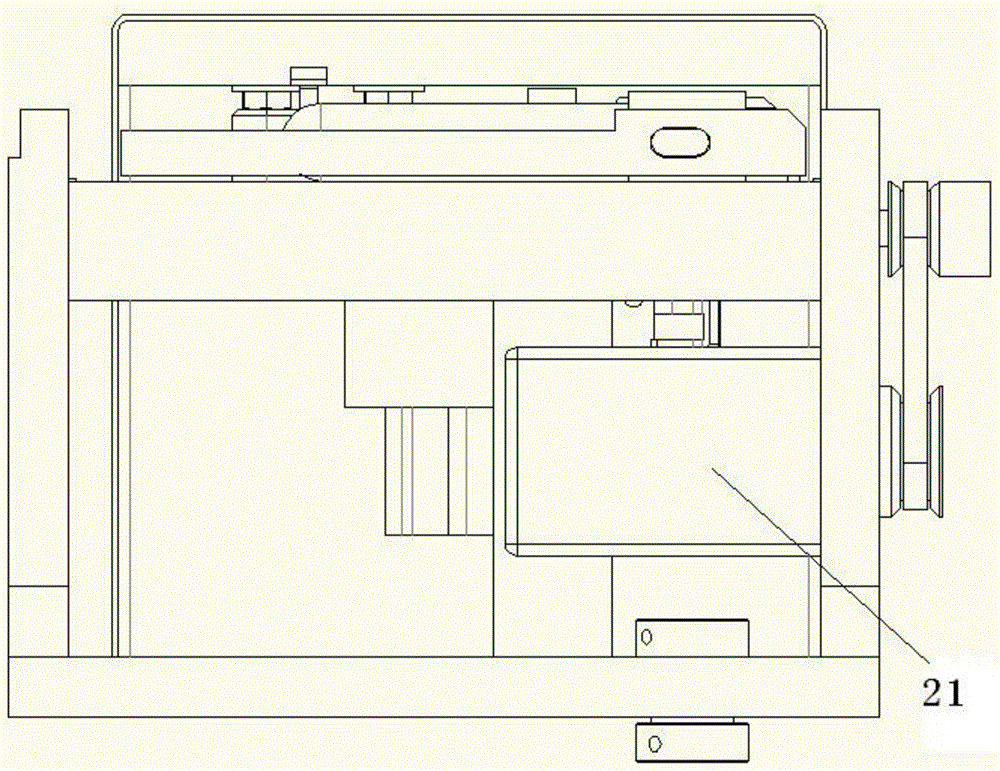

[0019] Such as figure 1 , figure 2 with image 3 As shown, a sorter pushing device includes a pushing mechanism and a material rotating mechanism. The pushing mechanism includes a pushing plate 18 and a pushing driving mechanism for driving the pushing plate 18. The material rotating mechanism includes a material rotating shaft 1 and a material rotating shaft 1. Drive the rotary drive mechanism of the material rotating shaft 1, the pusher drive mechanism drives the pusher plate 18 to transport the material on the pusher plate 18 to the material rotation mechanism, after the material is processed by the material rotation mechanism, the pusher mechanism then transports the material to Feed line.

[0020] Further, it also includes a controller, a zero return sensor 7 for detecting the position of the push plate 18 and a push sensor for detecting whether there is material on the push plate 18, the zero return sensor 7 and the push sensor are all connected with the control The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com