High-altitude mounting and dismounting method for heavy pin shaft

A pin and heavy-duty technology, which is applied in the field of high-altitude loading and unloading of heavy-duty pins, can solve the problems of difficult installation or disassembly of heavy-duty pins, and achieve the effect of solving difficulties in installation or disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

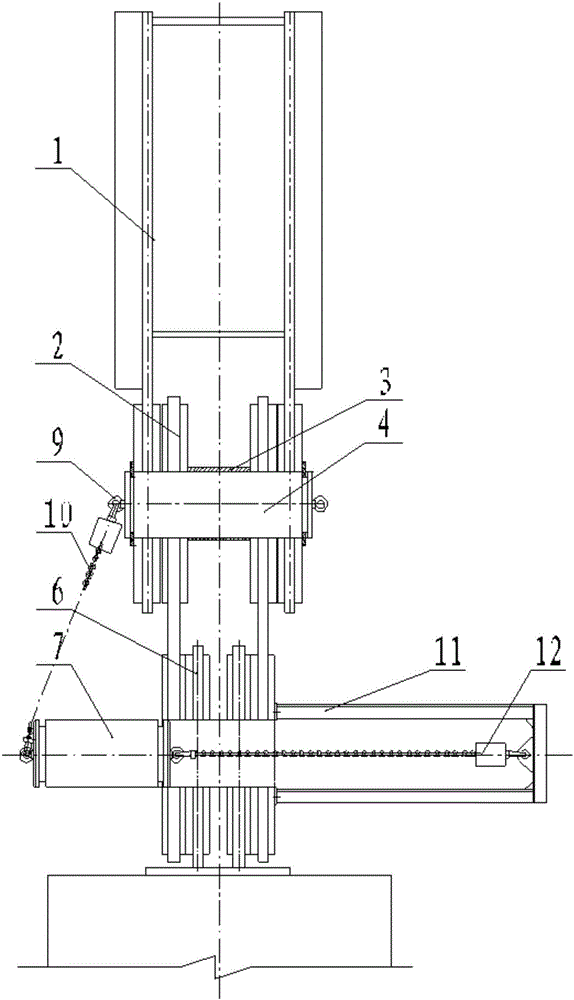

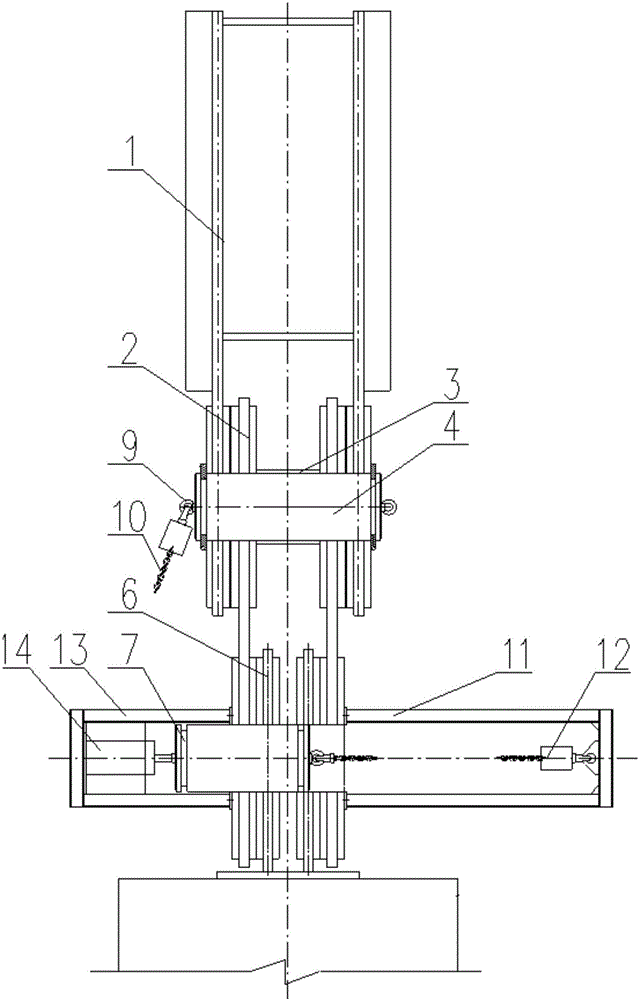

[0030] The embodiment of the present application solves the technical problem in the prior art that it is difficult to install or disassemble a heavy pin in high-altitude operations by providing a method for loading and unloading a heavy pin at height.

[0031] The technical solution in the embodiment of the present application is to solve the above-mentioned technical problems, and the general idea is as follows:

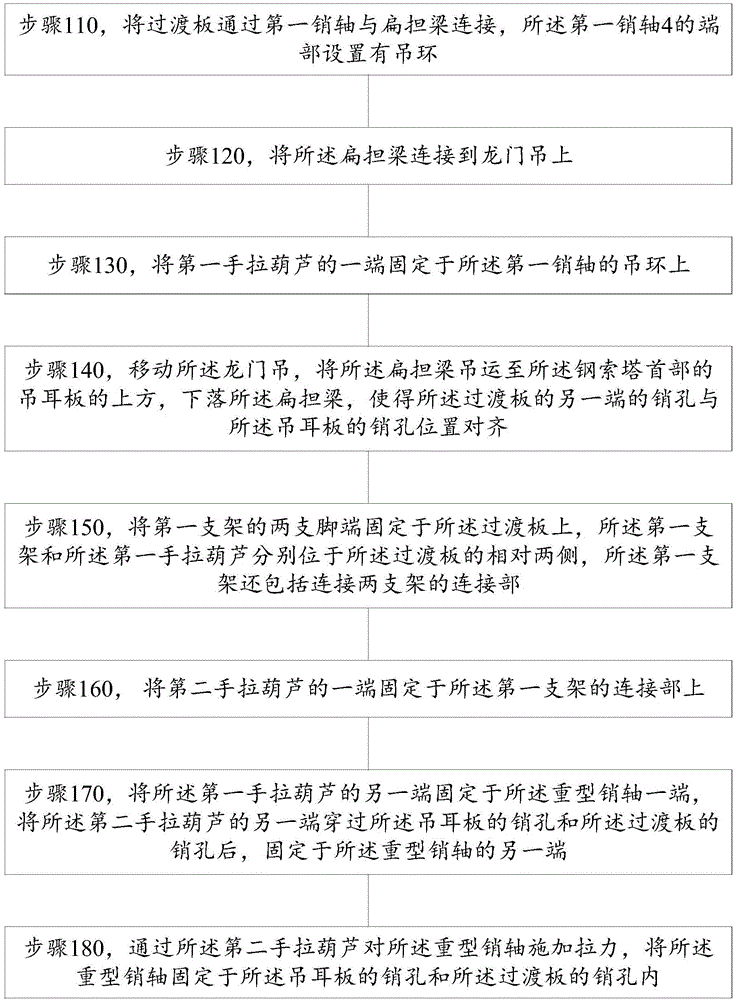

[0032] A high-altitude loading and unloading method for heavy pins, the loading and unloading method comprising:

[0033] Connecting the transition plate to the shoulder beam through the first pin shaft, the end of the first pin shaft is provided with a lifting ring;

[0034] The pole beam is connected to the gantry crane;

[0035] Fixing one end of the first hand chain hoist on the suspension ring of the first pin shaft;

[0036] Move the gantry crane, hoist the shoulder beam to the top of the lug plate at the head of the steel cable tower, and drop the shoulder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com