Lifting stand column with ultra-low installation distance

A technology of lifting column and installation distance, which is applied to the legs of general furniture, lifting devices, household appliances, etc., can solve the problems of low installation distance and the installation distance of lifting column cannot be further reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

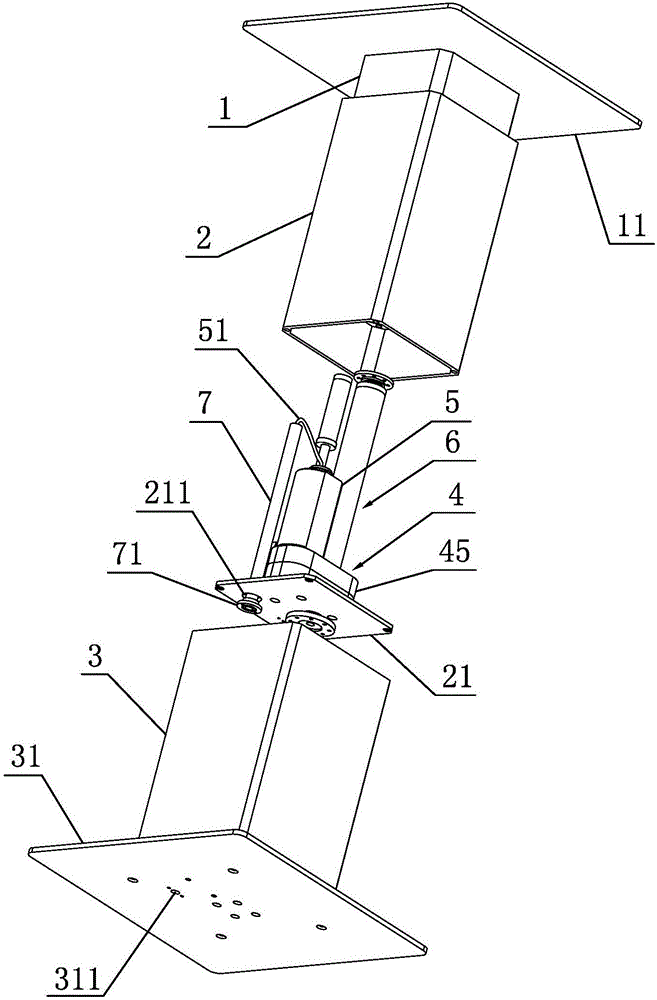

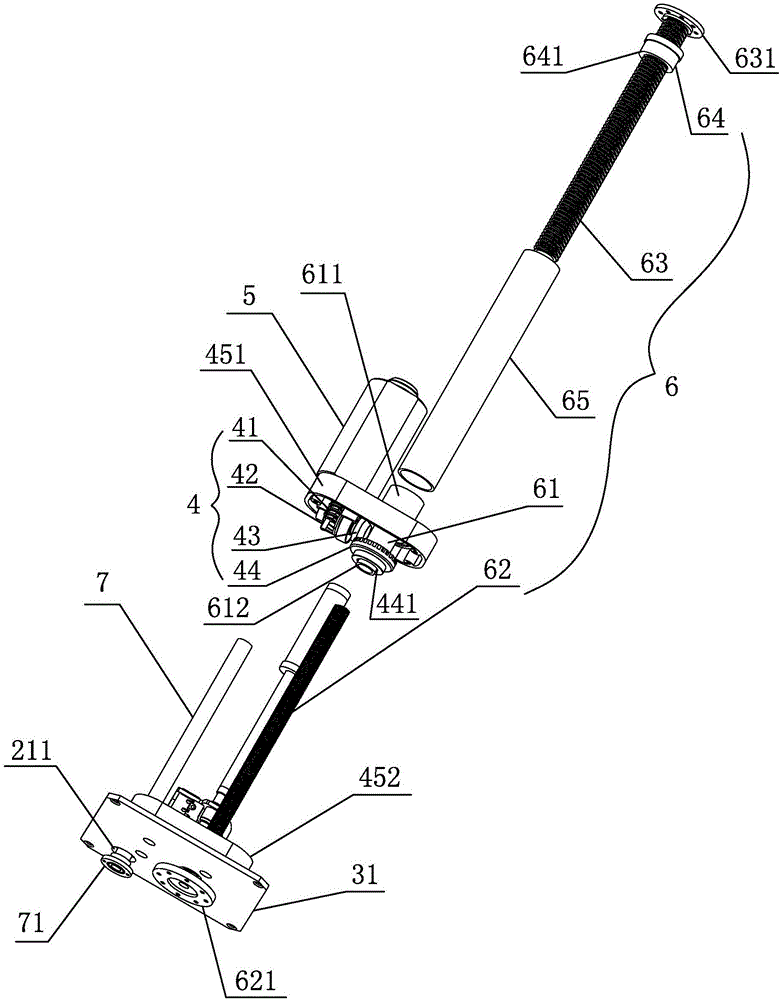

[0020] like figure 1 and figure 2 As shown, the present invention provides a lifting column with an ultra-low installation distance, including an inner tube 1, a middle tube 2 sleeved outside the inner tube 1 and slidingly fitted with the inner tube 1, and a middle tube 2 sleeved outside the middle tube 2 and connected to the inner tube 1. The outer tube 3 that the middle tube 2 slides fits, the bottom end of the middle tube 2 is connected with a middle plate 21, the bottom end of the outer tube 3 is connected with a bottom plate 31, and the middle tube 2 is provided with a transmission mechanism 4 installed on the middle plate 2, The drive motor 5 that is in transmission with the input end of the transmission mechanism 4 and the drive mechanism 6 that is in transmission cooperation with the output end of the transmission mechanism 4 and can drive the outer tube 3 and the inner tube 1 while reciprocatingly sliding relative to the middle tube 2, the drive motor 5 passes throug...

Embodiment 2

[0030] like figure 1 As shown, the difference between this embodiment and Embodiment 1 is that the sleeve rod 7 is an injection tube molded on the outer sheath of the power cord 51. The injection tube has a certain hardness, and the power cord can also be inserted along the middle The tube is supported axially.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com