Double packing self-cleaning anaerobic expanded bed bioreactor

A bioreactor and anaerobic expansion technology, which is applied in the field of anaerobic expanded bed bioreactors, can solve problems such as influent flow fluctuations and failure to update biofilms in time, and achieve the effect of avoiding mutual interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

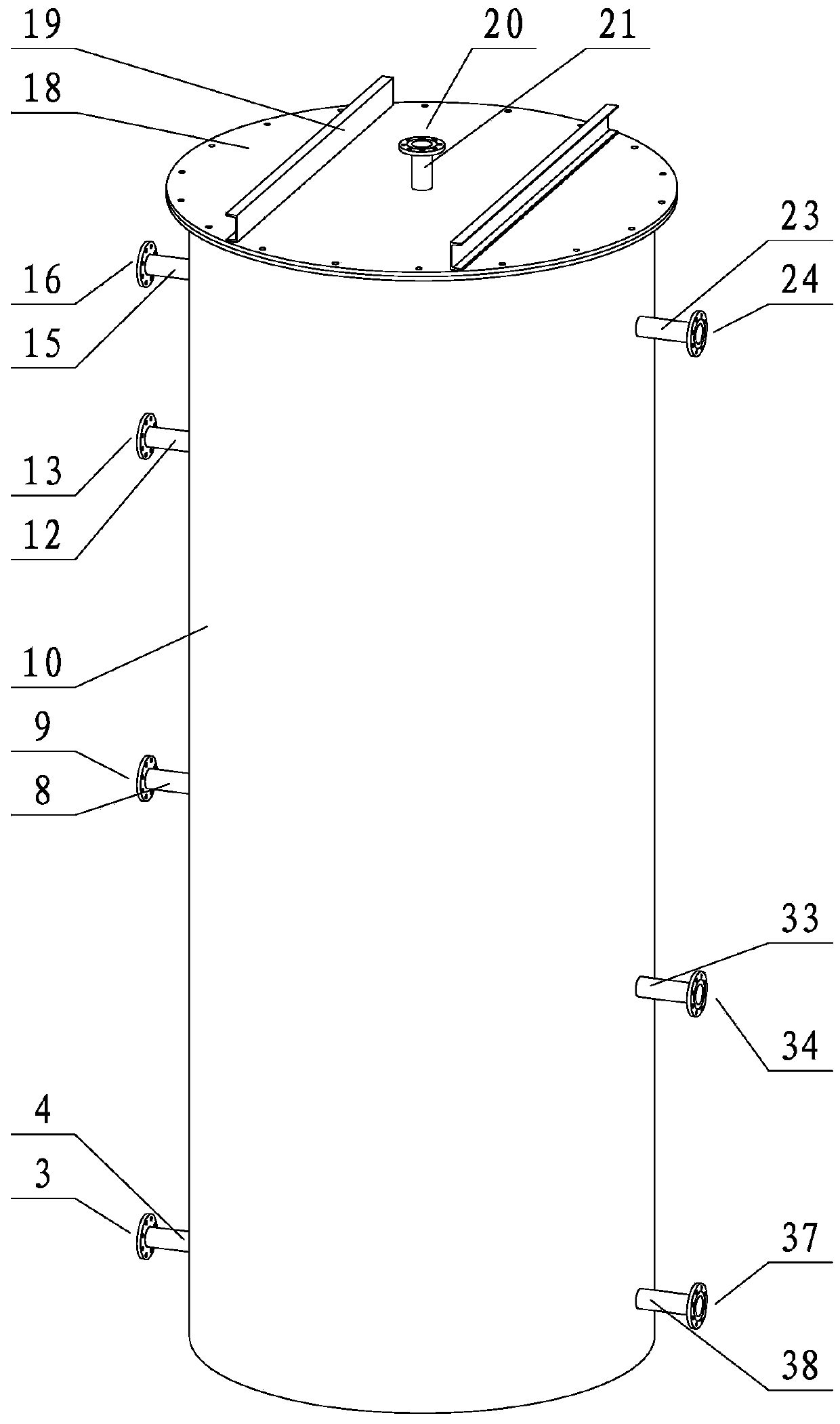

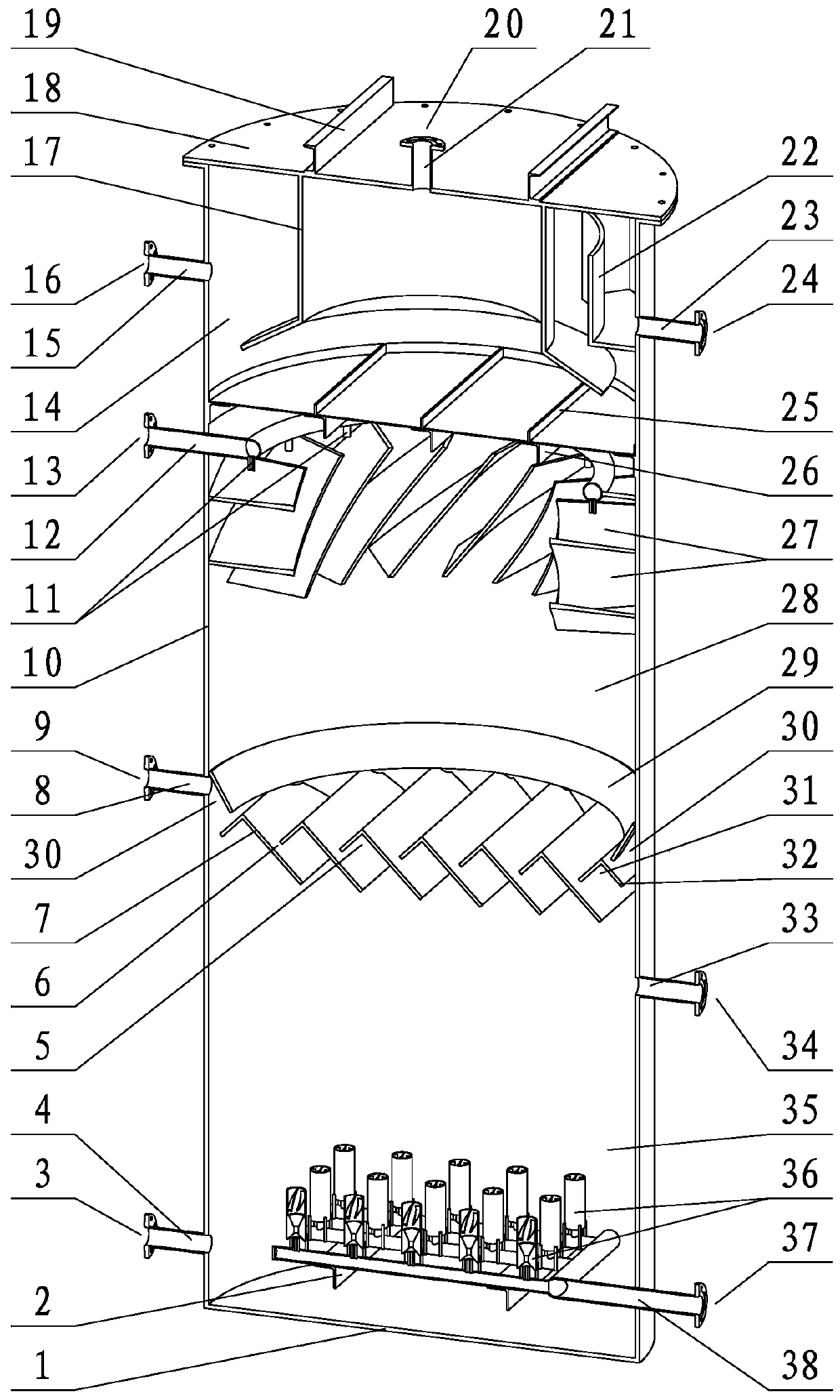

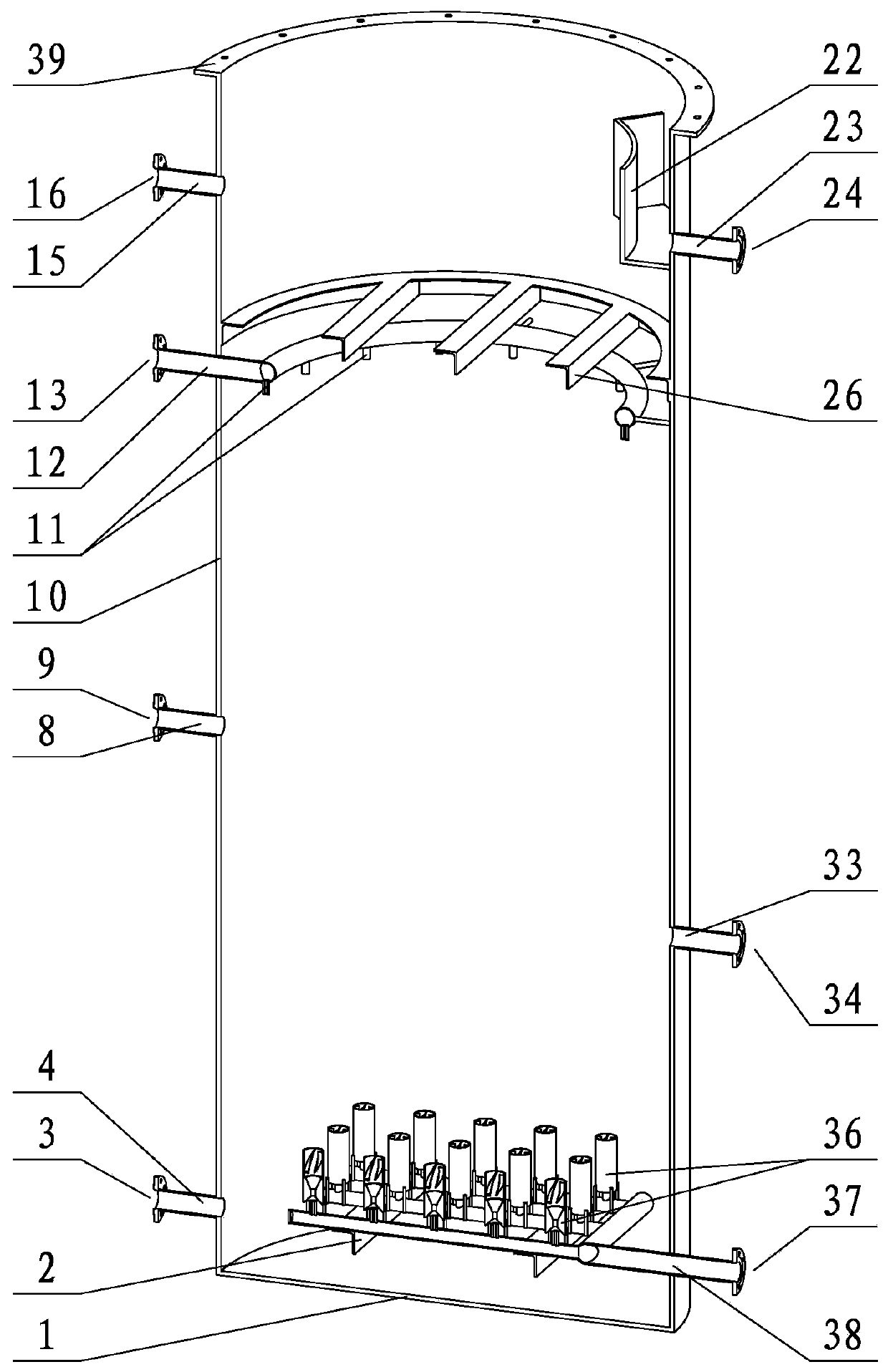

[0030] The present invention is further described below in conjunction with accompanying drawing.

[0031] refer to Figure 1 to Figure 14 , The anaerobic expanded bed bioreactor includes a tank body, an upper cover, a sieve plate part 25, a backwash water distribution pipe part, a spiral deflector part 27, a three-phase separator, and an expanded bed circulation water distribution pipe part. The backwash water distribution pipe components include an upper nozzle 11 , a backwash water distribution pipe 12 and an upper bracket 53 . The components of the expanded bed circulating water distribution pipe include a spiral injector 36 , an expanded bed circulating water distribution pipe 38 and a lower nozzle 58 . The expanded bed circulating water distribution pipe parts are installed at the bottom of the radially inner side of the tank body, the three-phase separator is installed at the middle part of the radially inner side of the tank body, and the sieve plate part 25, the back...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com