Electric tower stay wire sheath and manufacturing method thereof

A power pole tower and sheath technology, applied in the direction of towers, building types, buildings, etc., can solve the problems of easy breakage, easy occurrence of danger, and cable passing, etc., and achieves the effects of strong impact resistance, good protection effect and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

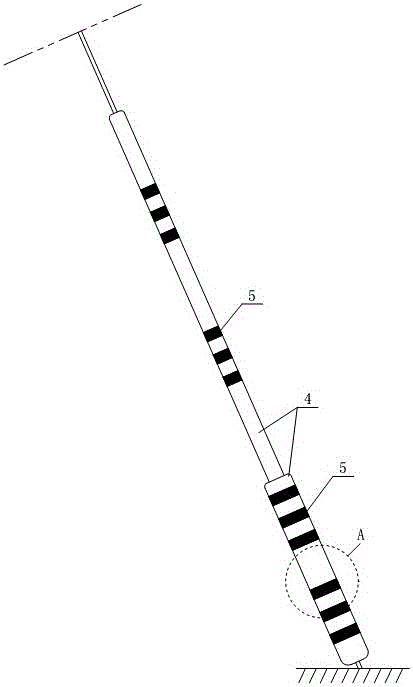

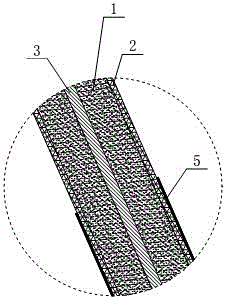

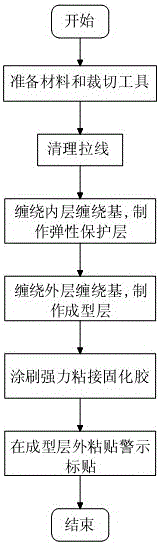

[0023] Referring to the accompanying drawings, the power pole tower stay wire sheath of the present invention includes a sheath body 4, the sheath body 4 includes an inner elastic protective layer 1 and an outer molding layer 2, the elastic protective layer 1 is made of elastic material and elastically protected Layer 1 is tightly wrapped on the bottom section of the backguy 3, the molding layer 2 is made of fiber braided material and the molding layer 2 is tightly wrapped on the outside of the elastic protective layer 1, the outside of the molding layer 2 is coated with a strong adhesive curing agent and strong The adhesive curing agent penetrates between the molding layer 2 and the elastic protective layer 1 and bonds the two layers into one structure, and a warning label 5 is pasted on the outside of the molding layer 2 . Wherein, the warning label 5 can adopt special warning paint, but in view of the complicated painting process and poor operability, the preferred warning l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com